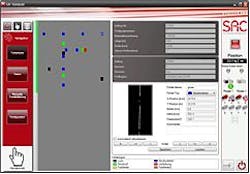

SAC VisionLine provides a modular system for web inspection

PRESS RELEASE

VisionLine, developed by imaging processing experts, is a modular structured web inspection system that inspects in real-time the continuous material's surface for homogeneity. When a deviation from the defined requirements is detected, the error classification decides if and which type of defect exists. With VisionLine, it is possible to detect several defects on continuous materials like paper, textile, metal etc.

An assortment of the defects identifiable by VisionLine:

• impurities

• ripped edges

• thin places

• pin holes

• crinkles

• stripes

• missing or scratched coating

• cracks

• holes

• colour differences

All VisionLine's system components like optics, hardware, and software are modularly designed. Because of their modular structure, VisionLine systems can be ideally adjusted to web widths and web speeds of different production lines. Moreover, the mechanical construction for the integration of the image processing system into the production process is an important factor, which will be specifically adjusted depending on the production area. The system’s control unit is where everything comes together. Questions concerning the defect’s description, the position, and the error’s classification will be responded and the collected data administrated. The downstream data management in addition allows the quantification of the webs as itself and also single details of each defect.

Operating software’s basis is our approved image processing interpreter Coake that has been especially adapted for VisionLine and has proved itself by more than 5,000 applications on the market. Coake will be completely programmed and evaluated for the respective VisionLine application with completed check commands by clicking of icons in the programme editor via drag & drop. The traceability of defects is given without any problems with Coake.

The benefits of VisionLine at a glance:

• 100 % continuous inspection of the product during the production

• traceability of the product at customers complaints

• error detection and classification for better production control

• optimal process control during the production

• increasing efficiency

• improved production quality

• easy integration into the production flow

Contact:

SAC Sirius Advanced Cybernetics GmbH

Am Sandfeld 15

D-76149 Karlsruhe

Fon +49 (0)721 60543-014

Fax +49 (0)721 60543-200

www.sac-vision.de

-- Posted by Vision Systems Design