FOOD PROCESSING: Hyperspectral imaging sorts blueberries

After harvesting, blueberries must be sorted to remove any impurities or unripe berries. While the majority of impurities are ejected by mature mechanical processes, fruit processors remove unripe (green/red) blueberries and any residual impurities using machine-vision systems that incorporate color cameras.

Organic impurities such as leaves, stems, beetles, or other insects as well as inorganic impurities such as plastics, wood, or glass, cannot generally be detected using typical color systems because the impurities will be colored blue by the juice of the blueberries and their shape may not be clearly distinguishable. In addition, impurities such as leaves, stems, stones, or insects may adhere to the blueberries and may not be detected even when manual picking and screening techniques are used.

Recognizing this, EVK DI Kerschhaggl GmbH (Raaba, Austria; www.evk.biz) has developed a system dubbed HELIOS Complete NIR that uses hyperspectral imaging techniques to detect impurities (see Fig. 1). The HELIOS system employs a hyperspectral camera, the HELIOS NIR, also developed by EVK. This camera incorporates an area-array, 320 × 256-pixel, 1.1–1.7-µm indium gallium arsenide (InGaAs) sensor that is operated such that separate 240 × 316-pixel line images are captured to provide a 240-pixel spatial resolution with a spectral signature across 316 pixels.

The blueberries are illuminated by standard halogen lamps while falling straight down a chute. Falling at 1 m/s, the 330-Hz full-frame scanning rate of the sensor then results in a 3-mm resolution in the down-web direction of the fall. Once captured, these images are processed within the camera and signals for ejecting impurities are provided to the ejection unit.

As may be expected, there are distinct differences between blueberries, blueberry leaves, stems, larvae, worms, and similar organic impurities as well between other inorganic impurities in the 1.1–1.7-µm near-infrared (NIR) range. Spectra have a distinctly different shape and can easily be distinguished from one from another, allowing simple data processing to return quantifiable results.

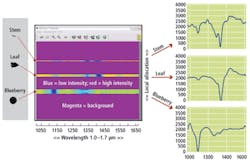

The Helios Viewer software allows the operating parameters of the camera to be set and the data visualized. This may be the spectra of the individual image points (or their derivation), the classified data for each image point, or the control signals for an ejection control mechanism. When represented as a 2-D color-coded spectrum of the individual image points, the spectrum shows a profile of a stem, leaf, and blueberry. As can be seen, the three spectra differ significantly and can therefore be classified by the system (see Fig. 2).

FIGURE 2. Profile spectra of a stem, leaf, and blueberry differ significantly and can therefore be classified by the system.

If a spectrum deviating from the background (shown in magenta) is detected, it will be shown color-coded on the corresponding local line. This color scale ranges from blue (low intensity) to red (high intensity). On the basis of the spectra recorded for each image point, Helios Class software can be used to set a classifier. This classifier is then used as the control signal for the ejection mechanism. Larvae, worms, stems, and stones can be identified in a similar manner. Only parts that are transparent to NIR cannot be detected by the system.

Vision Systems Articles Archives