Linescanning Lumber

Visually identifying and characterizing lumber before cutting increases the efficiency of wood production

Lumber mills are now deploying linescan cameras to identify defects in wooden planks. By doing so, cutting saws can be more effectively controlled to decrease the amount of waste while increasing the amount of usable product generated.

In deploying these systems, planks of lumber are scanned for defects with vision-equipped defect scanners. In turn, information from these scanners is then used to control material handling equipment that directs each plank to different transfer chains and then to saw blades that cut the planks according to the information provided by the defect scanner. This results in a number of defect-free pieces, each of a desired length.

One of the problems inherent in defect inspection systems is monitoring the sequence of the planks as they move through the system. Because the wooden planks are moved through the system on transfer chains, often planks can abut or overlap.

In some cases, if there is a large defect in the center of the wood, a plank can break into pieces. In such cases, multiple planks may be interpreted by the system as single planks and vice versa, resulting in the incorrect cut being applied to following planks.

The only method for detecting an out-of-sequence condition is by comparing the length and/or width of the plank of lumber to that given by the scanner. Once an out-of-sequence condition is detected, there is no easy way for the operator to know how to place the planks back in order. For this reason, production is halted and all the planks between the defect scanner and the cutoff saws are removed and placed back in queue for defect scanning. This operation is time consuming and costly.

Grain scanning

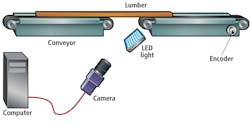

To overcome these limitations, Tisfoon Ulterior Systems has developed a system known as LumberID, which is used both to identify and track lumber in production processes (see Fig. 1). Because lumber is an organic material, it contains a unique grain pattern by which it can be identified. Thus, to identify and track lumber, the LumberID system includes a grain scanning station and a grain identification station.

With the lumber identification and tracking of the LumberID system, the sequence tracking problem is eliminated. By placing a grain scanning station before the defect scanner, the grain pattern of the first 18 in. of the plank of lumber is stored in a database. The cut solution calculated by the defect scanner is also placed into the database and associated to the grain pattern of the plank of lumber. A grain identification station is located at the cutoff saw to identify the incoming plank of lumber.

Once the plank is identified, its associated cut solution is retrieved from the database and transferred to the cutoff saw for processing. This solution solves the sequence tracking problem of the traditional system. Now the material handling system can convey boards with no regard to having to hold sequence to any cutoff saw. This makes the material handling system less complicated and thus less expensive.

Looking at wood

Both the grain scanning station and the grain identification station of the LumberID system employ identical hardware (see Fig. 2). As the wood enters each LumberID system, it is illuminated from below using a rectangular white LED light source measuring 9 × 4 in. with 108 LEDs that was custom built by Tisfoon.

To image the wood as it moves through the system, a 2k × 1-pixel monochrome FireWire LW-PE-2048-1394 CCD camera from ISG Chips (Fairport, NY, USA; www.isgchips.com) equipped with a 50-mm lens from Nikon (Melville, NY, USA; www.nikonusa.com) is triggered from a Turck (Minneapolis, MN, USA; www.turck.com) T8.5020.3422.1024 encoder. Captured images are then transferred to a host PC over the 1394 interface.

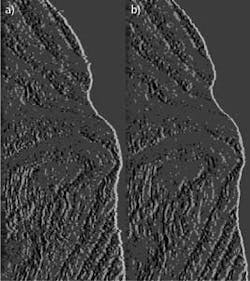

At both scanning stations, two different images are captured (see Fig. 3). Figure 3a shows an example of a grain pattern stored in the grain scanning station and Fig. 3b shows the same grain pattern as detected by the grain identification station. Although identical hardware is employed at both scanning stations, there will still be slight variations between the two grain patterns.

FIGURE 3. Although identical hardware is employed at both the grain scanning and identification stations, there will still be slight variations between the two grain images. To solve this pattern-matching problem, a heuristic algorithm was developed that scores the grain pattern derived at the grain identification station (b) against board grain patterns in the database (a). The highest scoring comparison is deemed to be the correct match.

Pattern matching

To solve this pattern-matching problem, a heuristic algorithm was developed that scores the grain pattern derived at the grain identification station against all the board grain patterns in the database. The highest scoring comparison is then deemed to be the correct match.

In the development of the LumberID software, Delphi 2010 by Embarcadero Software (San Francisco, CA, USA; www.embarcadero.com) was used. This object-oriented, Pascal-based language has the speed benefits of C++ and naturally enforces cleaner, less buggy code because of the typed nature of the Pascal language. Such a highly typed language forces the programmer to typecast all assignments such that the compiler will flag all mistaken non-typecast assignments.

Another software development challenge was the storage and compression of the grain pattern in the database. Grain information had to be small so that fast comparisons and scoring could be accomplished but at the same time had to preserve as much of the identity of the grain pattern as possible. This was accomplished by applying run length encoding (RLE) to the data and resulted in 10 kbytes of data for a plank 18 in. long and 3 in. wide.

By storing and displaying statistical data based on grain information from the scanning and identification stations, performance trends between the two stations can be calculated and monitored. Trends for these results are displayed for maintenance purposes and, if statistical differences of the grain patterns between the two stations become too great, maintenance personnel are alerted to perform calibration procedures.

The LumberID system has proven to be robust in the manufacturing environment. Minimal operator supervision is needed as no parameter changes are required when changing specific lumber types.

Amir Pirzadeh is president at Tisfoon Ulterior Systems (Cary, NC, USA; www.tisfoon.com).

Vision Systems Articles Archives