Laser scanning - It's not just a flash in the pan

A manufacturer of toilets for corporate jets has used a laser scanning system from NVision (Coppell, TX, USA) to reduce tooling costs and get a new toilet design to market faster.

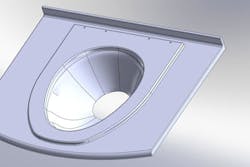

The main parts in the new toilet were the bowl cap, spray ring, and upper and lower bowl assembly. The normal approach to tooling up for a new toilet would have required all four parts to be designed from scratch and then a new thermoforming tool built for each part.

However, Mark Riebesehl, the owner of Aircraft Technologies, noted that an existing bowl cap and spray ring from one toilet and an existing upper and lower bowl from another were all close to the new design and would work perfectly if modifications could be made to the upper and lower bowl to make them fit together.

Unfortunately, the upper and lower bowl had been designed before the company started using CAD software, so there was no model that its designers could modify.

Instead, they decided to reverse engineer the existing upper and lower bowl tooling with help from NVision's Engineering Service Division, which scanned the two parts and created solid models from them. The CAD models were then modified to mate up with the existing bowl cap and spray ring, after which CNC programs were generated and tooling built on a machining center.

By using NVision's scanning services, only two tools instead of four needed to be built, a move that saved the toilet maker roughly $20,000. The scanning approach also helped the company get the new product into production four weeks earlier.

-- By Dave Wilson, Senior Editor, Vision Systems Design