Engineers at Moritex have developed a new system that can be used to inspect a variety of different needle types and geometries fully automatically.

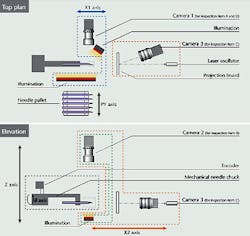

The Moritex system features three Basler (Ahrensburg, Germany) ace CCD cameras, lens optics, an LED lighting system and a diode laser for locating the needle that needs to be inspected.

The cameras capture images of a needle from three different angles, after which software measures its geometry and compares it a known good standard to enable any deviations to be detected.

According to Basler, leading Japanese medical device manufacturers are already successfully using the inspection system in the production of their needles.

More information on the design of the vision system is available on the Basler web site here.

Related items from Vision Systems Design that you might also find of interest.

1. Machine vision adds traceability to packaging

An automated vision system identifies cases of packed fruit and affixes barcode labels at a rate of more than 60 cases per minute.

2. Multispectral imaging plants roots in quality control

An automated vision system employs multispectral imaging techniques, 3-D mapping, and metrology to determine the quality of commercial plant seedlings.

3. Vision system blows the cover off powdered glass

An automated vision system analyzes the distribution and content of powder applied to glass prior to shipping.

-- Dave Wilson, Vision Systems Design