LED lighting targets machine vision

Advances in semiconductors, packaging, and intelligent control systems enable LED illumination to be more effectively controlled and maintained.

By Andrew Wilson, Editor

Recently, a number of lighting and illumination vendors have introduced novel products specifically designed to address applications in the automotive, semiconductor, and aerospace industries. Leveraging the latest developments in semiconductor and optics technology, these products often differ considerably from established designs, providing system developers with greater flexibility when choosing illumination systems for machine-vision applications.

While the luminous efficiency of white LEDs is currently 40 lm/W, the target, according to the Optoelectronics Industry Association, is to reach 150 lm/W by 2012. One of the two approaches to increasing the light output from LED lighting sources favored by companies such as Cree, Lumileds, and Osram is to produce single-power LED packages that can be attached to a printed-circuit board in tight clusters.

The other approach, favored by companies such as Enfis, Epitex, Lamina Ceramics, and Opto Diode, is to package a number of LED chips onto thermally efficient tiles that provide high power density and efficient light-emitting arrays. The advantage of the second approach is that multiple colors can be combined within the array to produce white light.

LIGHT ENGINES

Typical of these products is the range of light arrays produced by Opto Diode. The company’s OD-525-99-110, for example, features an array of 99 LEDs in a nearly square 1-in format. With a power consumption of 1.2 W, the light array produces a luminous output of 250 lm at a wavelength of 525 nm over a 100° beam angle.

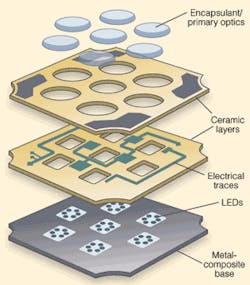

Using proprietary technology that has a multilayer, cofired ceramic-on-metal package, Lamina Ceramics also builds a range of light engines that use multiple high-brightness LEDs packaged into arrays. The company’s BL-3000 red LED arrays, for example, are configured with 39 cavities, each populated with multiple LEDs (see Fig. 1). Measuring approximately 1 in. sq, the company’s model BL-31A0-0122 consumes 104 W and can produce a luminous intensity of 2045 lm, a figure that the company claims makes the part the most powerful LED array available.

FIGURE 1. Lamina Ceramics LED light engines use multiple LEDs packaged into arrays. The company’s BL-3000 red LED arrays are configured with 39 cavities, each populated with multiple LEDs, and can produce a luminous intensity of 2045 lm.

In 2005, the company introduced its BL-4000 warm white LED array, which delivers 95 lm while consuming 5.3 W. Its usable lifetime (rated at 50% of original brightness) is three to four times longer than the longest-lived halogen. It is smaller than a US nickel, as are the RGB (red-green-blue) and cool white models in Lamina’s BL-4000 series.

“Lamina’s warm white LED light engine rounds out the BL-4000 series, which contains an RGB light engine producing 120 lm in up to 16 million blended colors-including white with variable color temperature-and a 120-lm, 5500 K cool white-light engine,” says Taylor Adair, Lamina Ceramic president and CEO.

“All of the company’s BL-4000 LED light engines are available mounted to Lamina’s EZ-connect board for solderless connections,” says Adair. “To protect the LEDs from ESD and provide an isolated metal base for adding a heat sink, developers can add optics and optics holders designed in partnership with Fraen.

CUSTOM PRODUCTS

“When designing smart LED light-engine solutions for our OEM customers,” says Gareth Jones, CTO of Enfis, “our company approaches the problem on a customized case-by-case basis, using in-house and outsourcing facilities to provide the most suitable solution.” To date, the company has produced a number of customized LED light engines, including an LED spotlight, large-area LED illuminator, and a high-power ultraviolet (UV) LED array developed specifically for nondestructive-testing (NDT) applications (see Fig. 2).

FIGURE 2. Enfis custom light-engine products include an LED spotlight, large-area LED illuminator, and a high-power ultraviolet LED array developed specifically for nondestructive-testing applications.

According to Jones, Enfis is currently in discussions with suppliers of UV systems for NDT who require an LED replacement for their lamp-based products to address the reliability, robustness, heat, and safety issues that occur with lamp-based products. Other companies, such as Cognex, are using LED combinations in products such as smart 2-D Data Matrix readers to provide on-axis, off-axis, and dome illumination to image difficult-to-read parts.

While manufacturers such as Enfis package a number of LED chips into their light engines, others such as Color Kinetics use the same terminology to describe their LED lighting modules. These are not true “light engines,” in the sense that multiple dies are not repackaged to increase luminous intensity. Rather, these companies repackage numerous off-the-shelf light LEDs into several different arrays to produce devices such as backlights, on and off-axis illumination systems, and dome lights.

FIGURE 3. Color Kinetics C-102 DLE is an illumination module intended for integration into OEM lighting products. An on-board microcontroller drives the LEDs, stores configuration data, and monitors the temperature of the sub-system. Separate red, green, and blue control channels enable color mixing of up to 16M different colors.

The Color Kinetics DLE C-102 digital light engine (DLE), for example, is an illumination module intended for integration into OEM lighting products (see Fig. 3). An on-board microcontroller drives the LEDs, stores configuration data, and monitors the temperature of the subsystem. Separate RGB control channels enable color mixing of up to 16M different colors. Driven by a current source, the DLE C-102 uses 755-mm LEDs whose intensity is controlled by pulsewidth modulation (see “Adding intelligent control to illumination and lighting,” p. 46).

NOVEL DESIGNS

As more powerful LEDs and LED illumination systems become available, developers of both lighting and illumination devices are taking advantage of them to develop novel products. In the design of its next-generation hand-held DataMan 7500 readers, for example, Cognex incorporated a custom LED design that offers on-axis, off-axis, and dome illumination. “For objects that are flat or gently curved such as printed metal plates, a diffuse on-axis light may be the best choice,” says Justin Testa, senior vice resident of Cognex. “Direct front lighting, however, can produce an image with excessive contrast. In such cases, important object features could be hidden by dark or bright areas in the image. In these cases, darkfield illumination is best used to illuminate the contour of the mark, enhancing embossed or engraved surface features.”

In other cases, the user may wish to read shiny, cylindrical parts marked with Data Matrix codes. In these cases, a diffuse off-axis or dome illuminator can evenly illuminate flat shiny surfaces and enhance scribed, indented, or embossed mark features. To read these parts, the LED lighting built into the DataMan 7500 can be automatically controlled by the reader itself. If a shiny cylindrical part needs to be illuminated, for example, blue LEDs can be automatically activated in a dome configuration to properly illuminate the part (see Fig. 4).

FIGURE 4. Incorporating adjustable lighting into its hand-held DPM reader allows the DataMan 7500 to read codes illuminated under darkfield illumination (left) and diffuse off-axis lighting conditions (right).

After parts are properly illuminated, the DataMan 7500 uses IDMax Data Matrix reading software based upon the company’s PatMax software to read the 2-D barcodes. “This allows the operator to read 2-D barcodes produced by dot-peen, laser, electrochemical etch, and inkjet markers on a variety of surfaces such as metal, glass, ceramic, and plastic,” says Testa.

Cloudy-day illuminators (CDIs) such as those found in the Cognex DataMan 7500 use an integrating sphere to produce a self-contained continuous diffuse-lighting environment. “CDIs can be used in applications involving objects inside clear packaging, such as blister-packed pharmaceuticals, by eliminating reflections from the clear cell coverings, making them virtually disappear while providing a high-contrast view of the cell contents,” says Marcel Laflamme, business manager at Siemens Energy & Automation, Nerlite Division (see Vision Systems Design, December 2005, p. 25).

“While such approaches are useful in many applications,” says Dirk Vermeersch, president of CCS Europe, “they suffer in applications that demand smaller, more flexible lighting configurations that can be more easily integrated into a machine-vision system.” To overcome these problems, CCS has developed and patented a novel “flat-dome light” that integrates the benefits of both coaxial and dome lighting into one compact lightweight flat design. In the design, each of CCS’s FLX LFX series of flat-dome panels consists of four arrays of linear LEDs that are mounted at the periphery. Light shining across the flat panel is then reflected downward by an array of hundreds of hemispherical arrays.

The light tunnels across the flat panel and reflects on both its top and bottom. When the light hits one of the hemispheres, it is scattered downward. “Although this at first sounds trivial,” says Vermeersch, “CCS developed a technology to position these microspheres so that they do not interfere with the light reflecting back from the inspected part into the camera. Vermeersch adds, “Each of the hemispherical arrays must be positioned at the proper angle to ensure the light is transmitted in a perpendicular fashion to the object under test” (see Fig. 5).

FIGURE 5. To illuminate glossy, curved, or uneven surfaces, designers can choose from diffuse on-axis illumination, “cloudy day” illuminators, or CCS “flat dome” light (left). Illuminating blister packs with coaxial and flat-domed lighting shows how the light can be used to better highlight possible pinholes (top). Lighting cans with domed and flat-domed lighting shows how both lights can increase type contrast (bottom).

According to Vermeersch, this was done by developing CAD models of both the LEDs and the coated hemispherical array. This has resulted in a patent-pending technology that provides uniform illumination over glossy surfaces while providing shadowless diffused illumination on objects with curved or uneven surfaces.

To compare the effects of its new flat-dome lighting with both coaxial and domed lighting, CCS engineers used the FLX LFX series to illuminate both pharmaceutical blister packs and the bottom surface of aluminum cans. “To detect pinholes in blister packs,” says Vermeersch, “a blister pack with red lettering was illuminated first with both coaxial lighting (the company’s LFV-100A) and the new LFX-100RD flat-dome light. While coaxial lighting eliminates the red lettering on the surface of the object,” says Vermeersch, “it cannot eliminate the specular reflection associated with the uneven surface of the film.” When the same part is illuminated with the flat-dome lighting, however, both the red lettering on the surface of the blister pack and the specular reflections from the film are eliminated. The pinhole defects can then be detected more easily.

To inspect the dot-matrix printing on the bottom of aluminum cans, CCS engineers used a domed light (PDM-150-15) and the LFX-100RD flat-dome light. “While using domed illumination provides uniform shadowless diffused lighting that highlights the dot-matrix printing, flat-domed illumination provides the same effect,” Vermeersch says.

Improving the performance of LED and illumination products that incorporate them will result in brighter, more stable lights with greater MTBFs. For the system integrator, advances in semiconductor, packaging, and intelligent control systems will allow low-cost LED lighting to be more effectively controlled and maintained by host-based vision systems.

Adding intelligent control to illumination and lighting

To allow illumination and lighting products to intelligently monitor light intensity and color, vendors such as Avago Technologies (Santa Clara, CA, USA; www.avagotech.com) and Texas Advanced Optoelectronic Solutions (TAOS; Plano TX, USA; www.taosinc.com) are building optical-feedback ICs that can analyze the color output of LED lamps and adjust their light output accordingly.

Avago Technologies is a company formed from the former Agilent Technologies Semiconductor Products Group. The company’s HDJD-J822 is a mixed-signal device designed to be the optical-feedback controller of an LED-based lighting system. In a system consisting of an array of red, green, and blue (RGB) LEDs and drivers, a tricolor photosensor samples the light output, and the HDJD-J822 processes the color information and adjusts the light output from the LEDs until the desired color is achieved.

The IC integrates a 10-bit ADC, color data-processing logic core, and 12-bit PWM output generator. By using a feedback system and the HDJD-J822, the light output produced by the LED array maintains its color over time and temperature. In addition, the desired color can be specified using a standard CIE color space. By incorporating a standard I2C serial interface, specifying the color of the LED array’s light output simply requires picking the color coordinates from the CIE color space and writing several bytes of data to the device.

The integrated color light-to-frequency (LTF) converter offered by TAOS combines a number of elements designed to reduce board space and increase functionality in embedded light-monitoring systems. Combining a photodiode, color filter, and trans-impedance amplifier on a single die, output from the device is fed to an external ADC for later processing. The integrated converter performs RGB color sensing using a photodiode grid consisting of 16 groups of four elements each. Output for each color is a square wave whose frequency is directly proportional to the intensity of the selected color.

Each group consists of a red sensor, a green sensor, a blue sensor, and a clear sensor with no filter. Since the LTF converter provides a digital output, color information can be input directly to a processor by sequentially selecting each color channel, then counting pulses or timing the period to obtain a value. This allows the sensor to be located remotely from the processor with no loss of noise immunity. - AW

Company Info

CCS Europe

Sint-Pieters-Leeuw, Belgium

www.ccs-grp.com

Cognex

Natick, MA, USA

www.cognex.com

Color Kinetics

Boston, MA, USA

www.colorkinetics.com

Cree

Durham, NC, USA

www.cree.com

Enfis

Swansea, UK

www.enfis.com

Epitex

Kyoto, Japan

www.epitex.com

Fraen

Reading, MA, USA

www.fraen.com

Lamina Ceramics

Westampton, NJ, USA

www.laminaceramics.com

Lumileds

San Jose, CA, USA

www.lumileds.com

Opto Diode

Newbury Park, CA, USA

www.optodiode.com

Optoelectronics Industry Association

Washington, DC, USA

www.oida.org

Osram

Danvers, MA, USA

www.osram.com

Siemens Energy & Automation, Nerlite Division

Weare, NH, USA

www.nerlite.com