Contact image sensors challenge linescan cameras

Andrew Wilson, Editor, [email protected]

High-speed web-inspection systems require high-resolution images to be captured by single or multiple linescan cameras that are deployed across the width of the web. With very high linescan rates, these cameras can capture images at high resolution across the transport width of the web. Because these systems are fast, they require cameras with very high sensitivity, a parameter only now being met by developers of high-resolution linescan cameras (see “Dual linescan imagers increase camera responsivity,” p. 8).

“These conventional “reduction-type” systems operate with a largely reduced image of the object,” says Christine Tichawa, managing director of Tichawa Vision (Friedberg, Germany; www.tichawa.de). “This is why the distance between the object to be inspected and the sensor need to be comparable to the width of the object. To capture a linescan image across a 2-ft web, for example, a linescan camera needs to be positioned approximately 2 ft above the object being inspected.”

One alternative is to use a contact image sensor (CIS) across the width of the web. However, like linescan cameras, conventional CISs are also limited in machine-vision applications. In office products such as photocopiers and flat-bed scanners, for example, these image sensors are placed very close to the object being imaged. Furthermore, they are not built to withstand rugged industrial environments, support high line rates, or interface to standard Camera Link or LVDS frame grabbers.

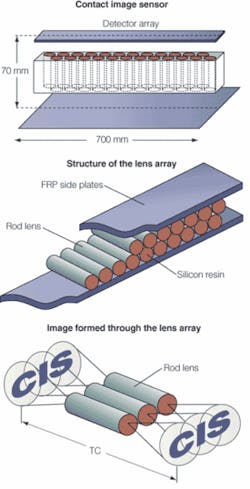

To overcome these limitations, Tichawa has introduced a series of CISs designed to meet the demands of the machine-vision industry. These contact image sensors are composed of an array of linear sensors, sophisticated on-chip optics, and an embedded light source. In Tichawa’s CISs, the sensor is made up of an array of either CCD or CMOS photosensors that are combined with support circuitry and stacked together to form a long detector.

Mounting an array of discrete photo-diodes linearly on a printed-circuit board at a pitch of 1 mm has allowed the company to develop its CIS 25, a sensor capable of imaging at a resolution of 25 dpi across a web width larger than 4 m. To meet more demanding applications, the company has also announced a sensor built around chip on-board linear CMOS sensors. With a pitch of 63.5 µm, these sensors can capture images at 200 or 400 dpi across an image field larger than 3 m.

What makes these image sensors unique is perhaps their use of sophisticated optics. “To allow these devices to be placed at a distance of 20 mm from the web-inspection surface, the sensors use an array of lenses developed by Nippon Sheet Glass (Tokyo, Japan; www.nsg.co.jp). “These lens arrays are composed of several graded-index lenses where light diffraction is not affected by the curved shape of the homogeneous lens but the graded change of the refractive index inside the cylinder shaped lens. This technique lends itself much better to mass production than conventional lens construction,” explains Tichawa. Since every single lens in the array forms an image over a limited region, the lenses are placed so that an overlap between individual images forms a sharp overall image over a long narrow line (see figure).

To correctly illuminate the object being inspected, system integrators can choose from either an integrated fluorescent tube with daylight characteristics or a long LED line. To interface Tichawa’s sensors to off-the-shelf frame grabbers, the company supplies a number of interfaces including LVDS and Camera Link interfaces, as well as Ethernet connectivity.

By developing these CISs, Tichawa has effectively overcome the limitations of conventional contact image sensors to offer noncontact, rugged, relatively high-resolution imagers with standard interfaces. The company expects to challenge the role predominantly held by linescan cameras in web applications.