Inside the Box

Winn Hardin, Contributing Editor

Food allergies affect up to 5% of the population, which is why a large food-processing company in North America needed a vision system to verify products packed in shipping cartons before sending the products out to market. The company turned to material-handling specialist the Numina Group to develop an automated system that could read labeled packages inside shipping cartons and check them against records in the customer’s enterprise resource planning (ERP) software program.

Because the products are already in cartons, making traditional UPC barcode scanning impractical, Numina asked vision specialist Vitronic Machine Vision to develop a package identification system. Vitronic offered a single- and multisided system composed of two linescan cameras mounted above the shipping carton conveyor.

The cameras take images of the open shipping container, locate individual packages inside, and then locate the product labels on the individual packages. The information along with images for archive and audit is returned via Ethernet to the Numina Group’s Carton Audit and Validation System (CAVS).

Crunching codes

According to Dave Dambek, chief operating officer at the Numina Group, CAVS detects UPC barcodes on labeled packages inside shipping cartons and determines whether the correct UPC and quantity of packages are present in each carton based on the company’s ERP system. If the carton is packed correctly, it proceeds to shipping. If not, the carton goes to a manual station with custom-designed CAVS interface to the warehouse’s ERP system.

As a carton approaches the CAVS station on a 30-in.-wide belt conveyor, a 1-D laser barcode line scanner reads a barcode from the front of the carton. The identifying number is sent as a query to the warehouse’s ERP system, which returns a manifest for each carton to the CAVS system.

The CAVS system creates a unique “token” or code to identify that carton for communications between the CAVS central processing unit and the Vitronic machine-vision system that will take a picture of the open carton, count the packages inside, locate UPC labels, and send the UPC codes back to the CAVS system for checking against the ERP record.

The VIPAC system includes two VICAMssi illuminated linescan cameras and a standard Windows-based PC running Vitronic’s VIPAC image-processing software. VIPAC includes both spatial image-processing algorithms, such as pattern match and edge detection, as well as optical character recognition (OCR) software for reading the UPC labels on the packages inside the carton.

For this audit and validation application, the CAVS/VIPAC system needed to be able to read 7–12 digit UPC-A, UPC-E, EAN-8, EAN-13, and CODE 39 symbology barcodes. VIPAC also has the capability to read handwritten labels, but that functionality was not used in this application.

Counting cartons

While the shipping carton’s manifest is downloaded to CAVS, a de-bounced photoeye sensor mounted on the side of the conveyor sends a 24-VDC trigger signal through CAVS, then via Ethernet connection to the VIPAC PC host. VIPAC, with autofocus camera control, triggers a pair of VICAMssi 8192-pixel linescan cameras with multiple taps, operating at 250 MHz, to start acquiring an image of the shipping carton as it passes underneath. When the carton passes the photoeye, a “stop acquisition” signal is sent back to the VIPAC PC (see Fig. 1).

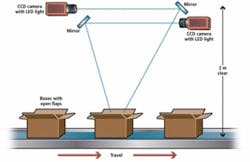

FIGURE 1. VICAMssi linescan cameras are mounted slightly off-axis to avoid reflection from the shrink-wrapped packages in the shipping containers. The conveyor must be rated to operate at constant speed to preserve the spatial integrity of the acquired image.

Each Ethernet-enabled camera ships with integrated bar lens for focusing the image onto the linear array, diffusion plate, and red LED line light inside the camera enclosure. The cameras are mounted 20° off the vertical axis to cut down on reflection from plastic-wrapped packages inside the shipping container and 2 m above the conveyor to provide adequate depth of field.

With the internal optics, this gives the system a spatial resolution of 200 dpi across a maximum conveyor width of 30 in., allowing the system to read any code with a width of 10 mil or more. The 2-m vertical standoff provides a depth of focus of ±2 in., which accommodates variations in package height inside the shipping carton.

“We used two cameras so that we could image a UPC label inside the container no matter how close to the sidewall, while still avoiding the reflection from plastic shrink-wrap,” explained Dambek. “To limit vibration that would negatively impact the images from the VIPAC system, Vitronic suggested mechanical dampening below the camera support frame and making sure nothing was attached to the frame, including pipes, sorters, or cable trays.”

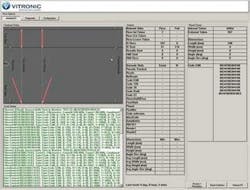

Once a full image is acquired from the linescan camera, the VIPAC software uses edge detection and pattern search algorithms to locate the individual packages inside the shipping carton. The packages located in the images from the two cameras are compared one against the other to make sure that both cameras see all packages and the count is correct (see Fig. 2).

FIGURE 2. VIPAC software GUI shows camera location and cameras’ FOV in the top-left Hardware Status window. As cartons are scanned, system messages appear in the bottom-left Event Viewer window and can be seen in greater detail by clicking the Diagnostic button. Green messages indicate normal operation; blue represents warnings; red indicates errors. The right side of this Managers screen shows how many cartons have been passed or failed and other performance statistics.

Then VIPC software searches for the UPC labels on each package. Finally, OCR software reads the UPC codes before sending the number of packages/labels, UPC codes, an image of the shipping container, and the carton “token” number back CAVS for comparison with the ERP record.

The CAVS logic compares the actual contents with the contents specified in the ERP download. The information is both stored locally on the CAVS system for 90 days and uploaded to the warehouse’s ERP system. If the contents of the shipping container are incorrect, packages bearing two or more product codes are in the same shipping container, or a label cannot be read, the VIPAC system sends an alarm to CAVS, which directs the packages to a manual inspection station.

At the manual audit station, an operator can scan the front barcode on a carton, and a display indicates the intended carton contents. The operator can then scan the UPC barcodes in the carton. CAVS determines whether the actual contents match the intended contents, indicates the result to the operator, and uploads the information to the ERP system.

Company Info

The Numina Group

Woodridge, IL, USA

www.numinagroup.com

Vitronic Machine Vision

Louisville, KY, USA

www.vitronic.com