Super Coal

Andy Wilson, Editor

After years of development and testing, a process has been developed that uses microwave technology and thermal imaging to control multiple properties of coal. The process, developed by CoalTek, increases the burn efficiency and BTU content of a broad range of raw coal fuels while simultaneously improving the overall environmental quality of the processed product.

After its founding in 2004, the company opened its first commercial processing facility in Calvert City, KY, in 2006. According to CoalTek, the plant’s initial capacity of 120,000 tons/year will be expanded in the future, and there are plans to build additional facilities to meet the growing demand for clean coal.

To increase the thermal efficiency of coal by as much as 50% while decreasing environmental compliance costs, the company’s 3-MW plant first subjects the coal to large amounts of electromagnetic radiation. “Using this process, low-BTU, sub-bituminous coal from Wyoming’s Powder River Basin can be converted to a high-heat, ultralow-sulfur product and thus act as an alternative to Appalachian and Colorado coal,” says Michael Druga, technology development manager at CoalTek.

Coal from Wyoming’s Powder River Basin is moist by nature and may contain impurities such as iron oxide or aluminum oxide. By eliminating moisture and impurities before it is shipped to coal-burning plants, the thermal efficiency of the coal produced is increased.

To process up to 120,000 tons/year, the coal is first loaded onto a conveyor belt where it’s partially heated by electromagnetic radiation. Any impurities such as iron oxide or aluminum oxide are more reactive to this radiation, while at the same time moisture in the coal is partially removed.

Thermal images

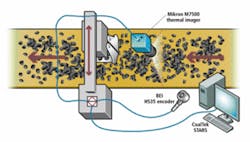

“Thermal images of the coal can be used to identify any impurities within the coal,” says Druga. “This coal can then be removed by a robotic-based system.” Before such a system could be installed, however, it was necessary to determine the best position in which to place the thermal imager. Because of this, Druga and his colleagues placed three different M7500 thermal imaging cameras from Mikron Infrared at various stages along the conveyor belt. After determining which images produced the most accurate representation of any thermal anomalies, the camera was placed mid-way between the initial and final drying stages (see Fig. 1).

After initial drying, the coal traverses the conveyor and is imaged by the camera’s 320 × 240-pixel uncooled microbolometer. “Because the speed of the conveyor is measured by an incremental encoder,” says Druga, “the distance between any defective coal and the position of the robot is known at every point.”

As the coal moves under the field of view of the camera, it is sequentially triggered by a PLC-based system from Factory Automation Systems. Captured images are then transferred over the camera’s Ethernet interface to a host PC.

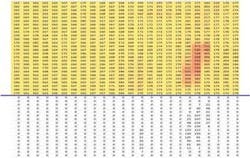

To locate any hot spots, the image is first translated into a bit-map with numbers that relate to peak temperature values (see top of Fig. 2). By taking a weighted average of these values and subtracting this value from the values within the image, any problem areas can be clearly visualized (see bottom of Fig. 2).

“By computing the size of this anomaly and its temperature, only specific coal samples with large amounts of impurities will be detected,” says Druga. Should the algorithm detect two such anomalies within the field of view, then the largest will be flagged as the location of greater interest. “However,” says Druga, “such occurrences are statistically very rare.”

No smoking

Written in Visual Basic, the Smoker Tracking and Removal System (STARS) developed by CoalTek is aptly named. Pieces of coal with impurities previously subjected to this process were often referred to as “smokers” because they would emit smoke after being subjected to the high-intensity electromagnetic radiation. “Since refining the process, however,” says Druga, “these ‘smoking’ effects no longer occur.”

In developing the STARS interface, it was necessary to allow the operator to closely monitor camera parameters, the temperature of the camera and the belt, and specific zones within the camera’s field of view (see Fig. 3). Defects, such as pieces of wire that may be present in the coal (bottom right) can then be visualized, along with the temperature of the impurity identified by zone as the coal traverses the belt from camera to robot.

After the locations of impure coal samples are detected, the coal must be removed from the conveyor belt. To accomplish this, the STARS application analyzes the thermographic image from the M7500 cameras and, upon detection of an anomaly, determines the location of that anomaly within the image. The corresponding coordinates are then written via Ethernet to a set of registers in the Allen-Bradley ControlLogix PLC that controls the robot developed by Factory Automation Systems.

The registers written include the x-axis coordinate based on the encoder value at the point of detection, the y-axis coordinate based on the location of the anomaly across the width of the conveyor belt, and a flag to alert the robot that an action is pending. Once the extraction is complete, the robot then closes the loop by communicating back to the STARS program with the status of the extraction as either a success or a failure based on the robot’s ability to reach the specified coordinates before the smoker passes (see Fig. 4).

null

Robot picking

Because the camera is located approximately 40 in. from the position of the robot, the size, temperature, and location of impurities can be monitored in real time. Depending on the size of this anomaly and its temperature, a decision is made whether to initiate robotic picking.

Equipped with a 4 × 4-in. bucket, this robot is capable of removing approximately 16 in.3 or 1.5 lb of material every 2 s. Because the coal is moving at a rate between 2 ft/min and 10 ft/min along the conveyor belt, the 2-s cycle time of the robot is fast enough to remove all the impure coal.

After the coal sample is picked by the robot, it is transferred to a take-away chute where it is removed from further processing. Any coal left on the conveyor is then transferred through a second electromagnetic drying station where any remaining moisture is eliminated. One of the side effects of this drying, of course, is increasing the temperature of the coal.

To avoid possible fire that this may cause, Druga and his colleagues are also studying deploying the system at the end of the production line. “If the temperature of the coal is too hot,” says Druga, “then the STARS system can be used to initiate a fire-prevention system to cool the coal after it is heated.”

In a similar manner as before, the coal is imaged and the temperature of a width of coal along the belt is analyzed. Should any coal be deemed too hot, then a PLC-based system is used to control a series of fine water sprinklers that independently spray water across the conveyor belt at intervals of 0.5 s.

“Evaporative cooling reduces the temperature without returning any moisture to the coal,” says Druga. Although the Calvert City pilot production plant consumes 3 MW to produce more efficient coal, the thermal efficiency of coal shipped to coal-burning plants is greatly enhanced, reducing pollution effects due to burning impurities. “This results in a near break-even point between the energy expended by the process and the energy finally obtained by producing cleaner coal,” says Druga.

Company Info

Allen-Bradley, Milwaukee, WI, USA

www.ab.com

CoalTek, Tucker, GA, USA

www.coaltek.com

Factory Automation Systems, Atlanta, GA, USA

www.factoryautomation.com

Mikron Infrared, Oakland, NJ, USA

www.mikroninfrared.com