FACTORY AUTOMATION - Smart cameras solve a pressing problem

Andy Wilson, Editor-in-Chief

Silver City Aluminum (Taunton, MA, USA) has been producing extruded aluminum products since 1952. Offering shorter tooling times at a lower cost than other metal forming methods, the extrusion process is straightforward. Billets of aluminum are fed into the extrusion machine, pressed into a die, and heated, emerging as a slat, blind, or other shaped aluminum product.

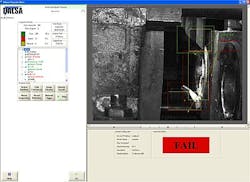

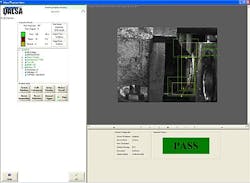

After the billet has been pressed into the die and heated for approximately 1 min, a knife drops down, guillotine-style, and shaves off the excess 3–4 in. of aluminum (see figure). Occasionally, after a billet has been cut, the excess aluminum fails to fall off. When this hanging piece hits the die, it can cause the machine to shut down, leading to a loss of production or to $10,000 in die replacement costs.

To eliminate such disturbances in production, Silver City's Larry Johnson contacted CPU Automation (Tyngsboro, MA, USA) for assistance. CPU Automation specified and installed a dual-camera inspection system using BOA smart cameras from Teledyne DALSA (Billerica, MA, USA).

As the billet is loaded into the press, one BOA camera inspects the billet to ensure that it enters the extruder properly. Since the press is located directly in front of a large window, infrared (IR) lights from Smart Vision Lights (Muskegon, MI, USA) are used to reduce glare and reflections, allowing a clearer view of the billet and preventing harm to workers' eyes.

As the knife drops to cut the billet and returns to its original position, the process is imaged by a second BOA camera. If the image indicates that the excess aluminum was sheared off, then the hydraulic press and plunger resume operations. If the image shows that the billet was not cut properly, the BOA initiates a programmable logic controller (PLC) from Allen-Bradley (Milwaukee, WI, USA) to stop the machine and activate an alarm, alerting workers to the problem.

To analyze images as they are captured, Johnson uses the library of vision tools supplied with the camera. At Silver City, a pattern-matching technique is used to determine whether the aluminum is properly cut. "We look at a clean cut and teach the system to run that specific pattern," says CPU Automation engineer Mike Bray. "Returned images provide a score of 100% if there is an exact match, and this score falls with any variations. Any large fluctuations that occur, for example, down to 20% cause the BOA to alert the PLC that a failure has occurred." Since the system has been running, Silver City Aluminum has not experienced any damaged die or machine downtime.

Both BOA cameras are interfaced to Johnson's PC, allowing him to control the cameras from his desk. Since the software is built directly into the camera, Johnson can program the BOA using a web interface.