HIGH-SPEED SCANNING - Machine vision digitizes vintage films

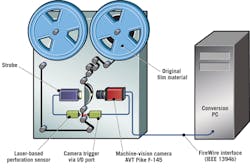

Using technology developed by Daan Müller, a lecturer for multimedia applications,FilmFabriek (Nootdorp, the Netherlands) has introduced a film scanner that uses a machine-vision camera to digitize film (see figure). With a Pike camera from Allied Vision Technologies (AVT; Stadtroda, Germany), the system allows professional film digitization to be offered to consumers and archives such as museums at a lower cost than traditional techniques.

In operation, the framescanner can convert regular 8-mm, Super 8, 9.5-mm Pathé, 16-mm, Super 16, and 17.5-mm frame formats to digital files. According to Müller, changing format setup can be accomplished in minutes by the operator. Changing formats requires the operator to exchange the gate and adjust the camera position and lens. This procedure can be seen athttp://bit.ly/dRoOIn.

Unlike many systems used to digitize films, the Müller HM Data Framescanner does not rely on projection or mirrors, nor does it use a consumer camcorder to capture the images. Instead, the Pike machine-vision camera from AVT is used to capture each frame directly from the film as it passes in front of a strobe light. Thanks to this choice, the achieved quality is close to the one used by professionals processing film archives for movie studios, television production companies, or other demanding clients.

The camera used is a Pike F-145, a digital camera with FireWire interface that employs aSony 1388 × 1038-pixel ICX285 CCD sensor chip. Thanks to the Sony ExView HAD technology used in the CCD, high sensitivity and image quality are achieved.

Müller has implemented a number of technologies into the scanner to optimize the digital output quality. First, a isopropanol fluid is applied to the film to temporarily remove scratches and mechanical damage from the film as it passes between the strobe and the camera. The fluid temporarily cleans the film and fills the scratches on the surface, making them invisible to the image-capture system.

Second, to guarantee stable images are digitized, the camera is triggered by a laser-based system that detects each frame change by analyzing the perforations on the side of the film. This enables the frame rate of the camera to perfectly synchronize with that of the film.

Each individually captured image is transmitted to a host computer over the camera’s FireWire interface (IEEE 1394b). As the theoretical maximum data throughput is 90 Mbytes/s, the scanning can differ between 25 frames/s at 1328 × 1000 pixels and 40 frames/s at 637 × 480 pixels. The data stream consists of uncompressed images, which can be transferred to any required output such as full HD.

Software converts the image stream into a progressive uncompressed AVI file to archive. Frame-by-frame output can be used for automated postproduction digital remastering. The operator may convert uncompressed film into any high-definition video format. After scanning, open source software such asAviSynth can apply sharpen, de-noise, saturation, scratch, and dust removal filters to improve image quality.