SMART CAMERAS: Smart camera eases press registration

Offset printing is a commonly used printing technique in which the inked image is transferred from a plate to a rubber blanket, then to the printing surface. Each ink or color is printed separately, resulting in offsets between the individual layers. To ensure that all the elements of the printing press are properly aligned, registration marks inscribed on the plate cylinder must coincide with each other after every stage of the color printing process.

If elements of the printing press are misaligned due to vibration or improper adjustment by the press operator, angular and offset error may occur. To ensure proper alignment of the printing press, print test runs are performed before the final press run is performed. In the manual performance of this task, the press operator examines any offsets on the registration marks that appear after a short initial press run.

After checking the position of these offsets, the operator then adjusts the press to compensate for any angular and offset errors that may occur. After entering the correct parameters, the procedure is repeated until the press is properly registered. Not only can this be a time-consuming process, but it is subject to human interpretation and, if not performed correctly, can result in a large amount of wasted paper and ink.

To make this setup procedure safe, easier, and more accurate, OptoMotive mechatronics Ltd. (Ljubljana, Slovenia) has developed a machine-vision system that automatically reads the registration marks, calculates the offset between each color, and visually indicates the press adjustments required to compensate for errors (see Fig. 1). A 752 × 480-pixel, 1/3-in. CMOS Cameleon camera from OptoMotive is mounted on a five-color rotary web offset printing press from Manroland (Westmont, IL, USA).

A Hall effect sensor from Honeywell is positioned on the press cylinder and optically coupled to the camera to synchronize the printing press with the camera. Since the time taken for one rotation of a cylinder is synchronized with the position of the press registration marks, the camera always captures an image of the positioning marker, which indicates if all colors were printed correctly and without offsets. The angular delay calculation is performed by the camera using the current trigger period.

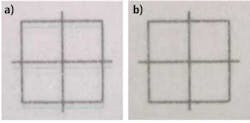

After the operator starts the press, images of the press registration marks are taken by the Cameleon camera (see Fig. 2). Each captured image is transferred to a host PC over a USB 2.0 interface and then compared with a reference image.

Proprietary software from OptoMotive running on the PC displays the image on the screen and warns the operator of any irregularity with the press. The operator then reads the offsets between layers from the displayed image and enters the corrections manually via the printing press control board, a process that takes 2 min.

Adjusting offsets between individual ink layers is common on rotary web offset printing presses, a setup that has now been simplified. Since registration marks are displayed on a PC, the operator no longer needs to manually remove paper from the press to for any potential misalignment of the press.

Vision Systems Articles Archives