AGRICULTURE AUTOMATION: Linescan-based system counts seeds

In the production and preparation of seeds for shipment to retailers and end users, different seed shapes and sizes must be accurately counted at high speeds. In the past, this process used photodiode-based systems that were relatively slow and difficult to adapt to a variety of seed shapes and sizes.

To accomplish this counting at rates of up to 1000 seeds/sec for a variety of seed shapes and sizes that range from 0.5 to 20.0 mm,Coleman Technologies Inc. (CTI; Newtown Square, PA, USA) has developed a linescan-based imaging system that provides such a throughput with a counting accuracy greater than 99%.

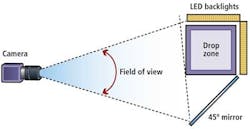

A Gigabit Ethernet Runner rul2048-19gm 2k × 1 linescan camera fromBasler (Ahrensburg, Germany) with an F-mount 75-mm lens is used to image silhouettes of seeds as they pass through a drop region in front of a pair of 6-in. EL138 high-intensity backlights from Advanced illumination (Rochester, VT, USA). To image a horizontal plane in this drop region, a mirror placed at 45° splits the field of view so the camera can simultaneously view the region from two angles 90° apart (see Fig. 1).

"Viewing the drop zone from two orthogonal directions enhances the ability of the system to distinguish seeds whose silhouettes overlap in just one view," says Michael Coleman, PhD, president of CTI. "The use of a single camera and mirror, as opposed to two separate cameras, significantly reduces system size and cost, in addition to simplifying the alignment of the two orthogonal camera views."

Each of the camera's fields of view acquires images at 19 kHz. Since the resolution of the system in the horizontal direction is 0.125 mm/pixel, this is sufficient to view very small seeds. With the linescan camera, the resolution achievable in the vertical direction is dependent on the velocity of the seeds. In the system developed by CTI, the optimum velocity of these seeds is from 2 to 5 m/sec, although the system can accurately count seeds at speeds faster than this at reduced seed throughputs.

To analyze the images as they are captured, a custom algorithm was developed usingLabVIEW from National Instruments (Austin, TX, USA) to associate seeds found in each view with seeds in the other view. In this way, it was possible to avoid double-counting seeds and to handle cases where seed silhouettes may overlap in one or both views. Additional routines used image-filtering techniques to avoid counting debris mixed with the seeds.

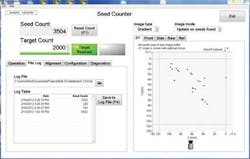

NI's LabVIEW and the NI Vision Development Module were used to perform image analysis on the data and present results in a graphical user interface (GUI) to the user (see Fig. 2). This GUI allows the user to set a target seed count and, once reached, triggers a digital output line on an NI USB-6008 data-acquisition module, which in turn controls a vibratory feeder. The application runs on a Vostro 460 fromDell (Round Rock, TX, USA).

This GUI also displays the images taken from each view angle and a plot of the position in the drop zone of each seed. Additional features include alignment and diagnostic tools, background correction, and configurable filtering parameters.

Currently, three systems have been installed in the facilities of a large international horticultural company. According to Coleman, the system can also be adapted to count other opaque objects, such as small food or manufactured parts at high throughput.