MATERIALS INSPECTION/PROCESSING: Off-the-shelf components combine for granule and powder inspection

Both the pharmaceutical and food industries require fast, highly accurate inspection systems for detecting and separating foreign materials from large batches of raw granules and powders. These bulk materials are generally encapsulated, made into tablets, or packaged into sachets by manufacturing companies.

To perform outer-appearance inspection of these materials, JPS Imaging Limited has developed an inspection system that uses off-the-shelf machine-vision components, processing material at the rate of 100 kg/hr for powders and/or granules with a density similar to that of granulated sugar (see Fig. 1). Food manufacturers also use it to inspect raw materials, such as flour or sugar, prior to mixing and processing.

Bulk granules or powders are continuously fed into a hopper and distributed in a uniform thin layer onto two vibrating conveyor feeders. Each conveyor has a set of six Flea3 1.3-Mpixel GigE Vision cameras from Point Grey (www.ptgrey.com) that continuously image the granule layer to locate defects.

Image data from these cameras are then transferred to three 4Sight industrial computers from Matrox Imaging (www.matrox.com/imaging), each equipped with a Matrox Solios image capture card. Each system has four cameras connected to simultaneously capture and analyze images from each camera at 30 frames/sec, analyzing images of 1280 × 960 pixels; typical defect sizes are 0.25 × 0.25 mm.

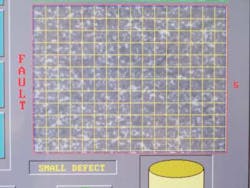

Images are processed using Matrox Imaging Library's (MIL) image-processing, measurement, and blob analysis modules. The inspection system can detect fibers and hairs approximately 0.1 × 2 mm long, black particles (e.g., insect parts, plastics, solids) as small as 0.2 × 0.2 mm, and bright or dark metallics as small as 0.3 × 0.3 mm (see Fig. 2). High-intensity OPT (www.optmv.com) LED bar illuminators provide even illumination across the width of the vibratory conveyor feeder. Any defective materials that are detected are automatically ejected via a slider mechanism.

The vision system is linked to a master PC system via a local network. This PC controls user input, live image capture, and image and system setups, and stores images of defects, which can be uploaded onto the factory network and viewed by personnel. Plant personnel can also access information such as inspection and error reports using the touch-screen interface.

Vision Systems Articles Archives