Inspection system boxes clever*

*Boxing Clever: Beyond thinking outside the box—re-defining the common thought process itself.

By Graham Manders

The production of corrugated boxes is performed by automated machinery that executes a variety of functions. First, corrugated board is printed, scored for folding, and cut to form box flaps. Next, glue is applied to one edge of each box, and the edges of the box are folded along the score line. Finally, the folded boxes are stacked prior to shipment.

While such boxes might not appear to be the most difficult products to manufacture, unless they are glued and cut properly, they can wreak havoc with automatic case erecting equipment at a customer's premises.

To ensure that they are, engineers at ClearVision (Vancouver, Canada), a subsidiary of Valco Melton (Cincinnati, OH, USA www.valcomelton.com), have developed a suite of three vision-based systems that work together to inspect corrugated boxes during the manufacturing process.

The first two of these systems - GlueChek - ensures that the appropriate amount of glue is applied to one of the edges of the unassembled box in a consistent fashion. The second system - FoldChek - inspects whether the dimensions of the gaps in the slots - a pair of closely spaced parallel cuts made in the box to form flaps - are within the customers specifications (Figure 1).

Should either the glue be applied inappropriately, or not at all, or if the gap sizes do not meet the specified tolerance, then the boxes are marked on their edges with a UV coating.

After the boxes are bundled together, any bundle containing a defective box is then marked again with UV ink and identified and rejected from the production line by the third BundleChek vision inspection system. An operator can then remove the defective box from the bundle.

Checking the glue

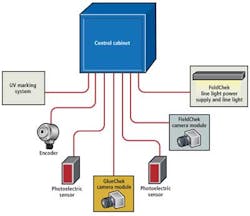

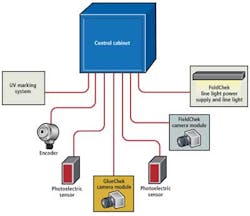

The GlueChek system itself comprises a photoelectric detector, an encoder, a camera module and a UV marking system. They are connected to a computer control cabinet called BoxChek.

The BoxChek control cabinet contains a motherboard with a CPU and a custom designed microprocessor/FPGA board that is used for triggering cameras, powering and timing the illumination systems and tracking the boxes through the machine from where they are first inspected by the GlueChek system, through the FoldChek system and on to the BundleChek system. The outside of the BoxChek system sports a touch-screen interface used to operate the inspection system.

The Banner Engineering (Minneapolis, MN, USA; www.bannerengineering.com) QS18VN6LAF photoelectric detector on the FoldChek system, which is positioned around 0.5m from the camera, is triggered when an object with sufficient dimensions - such as the box - passes underneath it on a conveyor belt. Any smaller items on the conveyor, such as scrap, will not trigger the system.

Data from the US Digital (Vancouver, WA, USA; www.usdigital.com) HD25-2500-F-N-H-I-D encoder enables the BoxChek controller to track the location of the box as it moves down the conveyor to the imaging station, through the FoldChek system and on to the UV marking system.

The custom-built GlueChek camera module contains a 1024 pixel Runner line scan camera from Basler (Ahrensburg, Germany; www.baslerweb.com), UV and white light LEDs from Seoul Optodevice (Ansan-city, Korea, www.socled.com) and Cree (Durham, NC, USA; www.cree.com), and custom optics that project a line of light onto the cardboard box to which glue with a UV additive has been applied (Figure 2).

After the system determines that the box is in the field of view of the camera, it is triggered by the BoxChek control system, capturing an image of the glue bead and glue tab onto which the glue has been affixed. The data is then transferred to the PC-based BoxChek control cabinet over a GigE interface.

Proprietary thresholding, edge detection and blob analysis algorithms written in C# then check several aspects of glue quality - including the profile of the glue beads, their consistency, length, and volume.

These parameters are compared with those extracted from a standard which the machine has been taught previously. This is accomplished when an operator selects what is considered to be an acceptable representative image of glue on the box, as an initial run of boxes passes under the image inspection system.

If the glue has not been applied to the box in the appropriate fashion, the operator is alerted through an image on the touchscreen and the defective box is marked for removal on its leading edge by the UV marking system.

Mind the gap

Having checked each box to ensure that the glue has been applied appropriately, the FoldChek system ensures that the gap sizes on all the boxes are within the customer's specifications (Figure 3).

The FoldChek system uses the same data from the photoelectric detector and encoder on the GlueChek system to track boxes through the system. It also includes a custom built camera module that contains a white light LED light bar and a Basler camera that are interfaced to the same BoxChek control cabinet as the GlueChek system.

For the FoldChek system, specialized lighting was required to enable the camera to capture images of the gaps. Mounted 5ins away from the box, the white light LED light bar projects light in two 45° directions simultaneously. One produces shadows on one edge of the gap in the box and the other shadows on the other edge, enabling the images captured by the camera to distinguish between the edges of the gap and print on the box.

Once triggered, the Basler 2048 pixel Runner camera in the camera module captures images of the area around the gap which are transferred to the BoxChek cabinet over a GigE interface.

To inspect the dimensions of the gaps cut into the box, edge detection algorithms are used to find pixels in the image that represent the horizontal and vertical edges of the gaps.

Custom software running on the BoxChek controller then determines whether the gaps fall out of the tolerance range of a known standard image which was captured prior to a production run. If a defective box is identified, the operator is alerted through the touchscreen and the defective box marked for removal on its trailing edge by the marking system. Due to the speed of the production process, the box after the defective box is marked with UV ink as an indication that the previous box is to be removed.

Because the GlueChek and FoldChek systems mark the boxes with UV ink at different locations on their edges, an operator can easily identify and then remove the correct defective box from a bundle at a later stage in the production process.

Bundled up

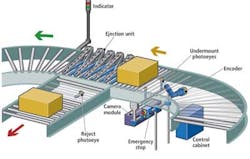

The third element to the ClearVision inspection system is known as BundleChek, which works with the GlueChek and FoldChek systems to eject bundles containing defective boxes (Figure 4).

The BundleChek system consists of a pair of QS18VP6AF100Q5 photo eyes from Banner Engineering (Minneapolis, MN, USA; www.bannerengineering.com), a set of five pneumatic lifting arms, a control cabinet, a camera module with a 2048 pixel Runner camera from Basler (Ahrensburg, Germany; www.baslerweb.com) with integrated LED lighting and a second UV marking system.

Because the BoxChek system tracks defective boxes as they move down the conveyor, when a bundle of boxes with a defective box in it reaches the BundleChek system, it is automatically marked on the bottom with UV fluorescent dye.

To do so, the pair of photo eyes detects the positions of bundles on the main conveyor, triggering the camera and LED unit. The image data from the camera is then transferred to a PLC-based (Siemens, Nuremburg, Germany; www.automation.siemens.com) control cabinet in the system over a GigE interface. This relays the image data back to the BoxChek system for analysis over an Ethernet interface.

If the system software detects that a UV mark has been applied to the bundle, the BoxChek system instructs the PLC to actuate the five pneumatic lifting arms after an encoder has determined when a bundle has reached the ejection unit.

The ejection unit diverts the bundle to a secondary conveyor known as the reject conveyor. A photo electric sensor on the reject conveyor detects whether the reject conveyor has become full. If it has, the operator is alerted on the touchscreen panel of the control cabinet.

The machine operator can then sort the defective box from the bundles when time permits. Depending on whether the mark is on the leading or the trailing edge of the box, the operator can determine whether it is a FoldChek or a GlueChek defect. If it is a GlueCheck defect then the box is removed from the stack. If it is a FoldCheck defect, the previous box is removed.

Machine interaction

All interactions with the inspection machine are performed through the custom software via the touch screen user interface on the control cabinet. The software enables an operator to see a live image of the most recent box to be inspected and whether it has passed or failed inspection (Figure 5).

An image of the glue pattern, or dimensions of the gaps cut into a standard box, is displayed for reference. A green check mark beside the image is used to signify that it has passed the inspection, while a red cross signifies that it has failed. Order specific information is also displayed on the screen such as production rate, defect rate and order number.

Operators can also review defects from past or current orders because the system saves and archives images of every defective box by customer order number. The standard images to which the boxes were compared to is also saved for reference.

Graham Manders is the Vice President of Engineering at ClearVision (Vancouver, Canada), a subsidiary of Valco Melton.

Company Info

ClearVision/Valco Melton

Cincinnati, OH, USA

www.valcomelton.com

Banner Engineering

Minneapolis, MN, USA

www.bannerengineering.com

US Digital

Vancouver, WA, USA

www.usdigital.com

Basler

Ahrensburg, Germany

www.baslerweb.com

Siemens

Nuremburg, Germany

www.automation.siemens.com

Seoul Optodevice

Ansan-city, Korea

www.socled.com

Cree

Durham, NC, USA www.cree.com

Vision Systems Articles Archives