IMAGE SENSORS: Organic imagers challenge silicon-based detectors

While most vision systems currently use silicon-based photo-detectors to capture images, many companies and researchers are currently studying methods that replace these detectors with organic compounds.

To build these imagers, two different approaches are being pursued. The first replaces the conventional silicon photo-detector with a light sensitive organic compound. A conventional silicon-based read out circuit is then used to transfer data from the imager. In the second approach, the conventional silicon-based light sensitive photo-detector is replaced with a light-sensitive organic compound and the read-out electronics are fabricated on a plastic organic thin-film transistor backplane.

Taking the first approach, researchers at the Prof. Paolo Lugli and Dr. Daniela Baierl from Technical University of Munich (TUM, Munich, Germany;www.tum.de) have developed an image sensor based on a photosensitive polymer layer sprayed on top on the silicon ROIC (http://bit.ly/18GFdUo). By using different chemical compounds different parts of the spectrum can be imaged. While some polymers are ideal for the detection of visible light, other organic compounds are sensitive to light in the near-infrared region.

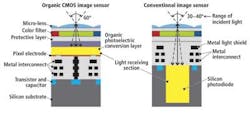

Taking this same approach, Fujifilm (Tokyo, Japan;www.fujifilm.com) and Panasonic (Osaka, Japan; www.panasonic.com) have collaborated on the design of a CMOS image sensor that uses an organic photoelectric conversion layer of 0.5 microns. This results in an imager with 88dB dynamic range and an increased light incident angle (http://bit.ly/1cGoAg2).

To build flexible organic image sensors two different European development teams have developed fully organic photo-detectors by depositing organic printed photo-detectors onto a plastic organic thin film transistor backplanes. Applications for such devices could include their use in digital X-ray imaging where the organic image sensors would replace amorphous silicon. For such applications, a flexible image sensor could, for example, replace the ridged flat panel sensors currently used in intraoral radiography.

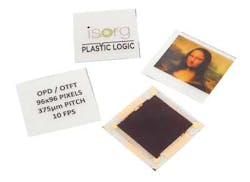

Imagers based on this technology were first demonstrated by a collaborative team from IMEC (Leuven, Belgium; www2.imec.be) and the Holst Centre (Eindhoven, The Netherlands;www.holstcentre.com) at last year's 2013 International Image Sensor Workshop (IISW) in Utah, USA and by a team from ISORG (Grenoble, France; www.isorg.fr) and Plastic Logic (Cambridge, England; www.plasticlogic.com) at the LOPE-C 2013 printed electronics conference in Munich, Germany.

In collaboration with Phillips Research, the organic imager developed by IMEC and the Holst Centre is targeted at x-ray imaging applications where light weight, large area organic semiconductors on flexible foils can be deployed. With an array size of 32 x 32 pixels and a pixel pitch of 200 microns, the IMEC organic photodiode layer is semi-transparent to visible radiation.

According to Dr. Pawel Malinowski, Researcher in Organic Electronics at IMEC, the device is expected to be more resistant to radiation than inorganic photodiodes due to its lower capture cross-section and low thickness of the active layer. Currently, Malinowski is working on the next generation organic imagers that will use an Indium gallium zinc oxide (IGZO)-based backplane technology to offer better performance than organic or amorphous silicon transistors. This will also allow an increased array size and smaller pixel pitch.

Like IMEC and the Holst Center, ISORG and Plastic Logic have collaborated in the development of an image sensor based on the deposition of organic printed photo detectors, pioneered by ISORG, onto a plastic organic thin-film transistor backplane developed by Plastic Logic. The flexible sensor features a 4 x 4 cm active area, a 94 x 95 pixel array with a 375 micron pitch. The backplane design, production process and materials were optimized for the application by Plastic Logic resulting in a flexible, transmissive backplane.