Tunable lenses find novel applications

Andrew Wilson, Editor

In manufacturing environments, objects of different heights may need to be imaged as they move along a conveyor. In such applications, a number of different approaches can be used to ensure that images are captured in focus. These include deploying mechanical systems to reposition the camera and lens system, using cameras with a large depth of field or by integrating mechanically-driven zoom and/or auto-focus lenses. In contrast, a number of companies now offer adaptive lenses that can be tuned over various focal distances. Smaller, faster and more compact than traditional autofocus designs, these lenses are finding use in a number of machine vision and microscopy applications.

Today, a number of disparate technologies are used to perform autofocusing that include devices based on electro-optical, electro-mechanical and acousto-optical techniques. While electro-optical devices such as the Arctic family from Varioptic (Lyon, France;www.varioptic.com) are based on an electro-wetting principle, the EL range of tunable lenses from Optotune (Dietikon, Switzerland; www.optotune.com) use a combination of optical fluids and a deformable membrane. Other approaches, such as those from TAG Optics (Princeton, NJ, USA; www.tagoptics.com) uses standing sound waves to produce a constantly changing gradient index of refraction within a liquid contained in the lens.

Water and oil

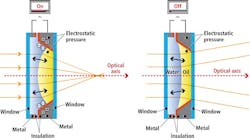

Varioptic's liquid lenses consist of a water and oil combination each of which have the same density but different refractive indices. Here the electrically conducting water solution and electrically non-conducting oil form a natural diopter due to the different indices of refraction of the two liquids. By applying an electric field, the radius of curvature of the meniscus between the two fluids changes ,resulting in a change in the focal length of the lens (Figure 1).

While such lenses can be manufactured relatively inexpensively, the low capillary forces involved make it difficult to build lenses with large apertures. The largest aperture lens - the Arctic 39N0 liquid lens from Varioptic, for example, measures 3.8mm in diameter while the Visayan series starts with an 8mm clear aperture. Since the focal lengths are voltage controlled, the company's liquid lenses are supplied with a USB-powered power supply that allows the lenses to be controlled either manually, through an analog input or using the company's PC-based FocusLab software.

In the Varioptic booth at VISION 2014, the company showed how its products could be integrated with third-party cameras and embedded into stand-alone products. There, Olivier Jacques-Sermet, Sales Manager at Varioptic, showed how PixeLINK (Ottawa, ON, Canada;www.pixelink.com) had used a variable optic lens fitted to a PL-D722 USB camera to produce a variable focus camera. In the demonstration, the contrasts of images at different focal lengths were automatically analyzed allowing the system to perform an automatic autofocus. Also on-show were a number of embedded products that had used the liquid lenses in hand-held bar code scanner designs. These included the Dataman 200, 300 and 8000 Series from Cognex (Natick, MA, USA; www.cognex.com), the QX Hawk from Microscan (Renton, WA, USA; www.microscan.com) and other hand-held scanners from Opticon (Renton, WA, USA; www.opticonusa.com) and Datalogic (Bologna, Italy; www.datalogic.com).

Polymer membranes

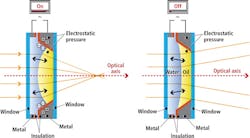

Rather than use electro-optical techniques in their tunable lens design, Optotune have chosen an electro-mechanical approach. In this approach, an optical liquid within a container is sealed with a thin, elastic polymer membrane. Two methods are used to shape the tunable lens. In the first method, used in the company's ML-20-35, a 20mm manually tunable lens, the ring that forms the lens is pushed towards the container filling the lens with liquid (Figure 2a).

In the second method, used in the company's EL-10-30 10mm aperture lens, the lens shaper ring remains in place relative to the container. The only movement is a voice coil that presses down on the membrane at the outer part of the lens, thus pushing the liquid into the center where the membrane deflects in a spherical shape, which results in a change of the focal length of the lens. The curvature of the EL-10-30 shape-changing polymer lens is adjusted by applying current and the focal length is accordingly tuned to a desired value within milliseconds (Figure 2b).

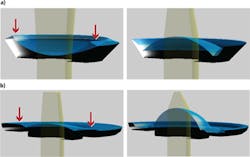

At last year's VISION show, Edmund Optics (Barrington, NJ, USA;www.edmundoptics.com) demonstrated how these tunable lenses could be used to electronically adjust the focus of the company's lenses. In two demonstrations, Lucas Willis, Vision Solutions Engineer, showed the tunable lenses fitted to both a 5x finite conjugate objective lens and how it had been integrated into the company's Dynamic Focus VZM Lens. In the first demonstration, an Optotune lens fitted to the finite conjugate lens was shown imaging two test targets placed on top of one another. In the second demonstration, a comparison of the company's Dynamic Focus VZM Lens was compared with a standard VZM Zoom imaging lens. By dynamically adjusting the focus of the Dynamic Focus VZM lens at a 2Hz rate, images of the top and bottom of the circuit board being imaged can be visualized simultaneously (Figure 3).

Optotune demonstrated a number of different cameras and systems based on its tunable lens technology at the VISION show in Stuttgart. In one demonstration, the company showed how an acA2500 USB3 camera from Basler (Ahrensburg, Germany;www.baslerweb.com) fitted with the company's EL-10-30 10mm tunable lens and a 25mm lens from Schneider Optics (Hauppauge, NY, USA; www.schneideroptics.com) was used to capture images at different focal distances placed on a simulated production line, whereas the focus was controlled automatically by a distance sensor.

SANXO-Systems (Budapest, Hungary;www.sanxo.com) has developed a similar system called the SANXO-Scope HD. Originally developed for the inspection of printed circuit boards, the system consists of a 10Mpixel GigE camera from IDS Imaging (Obersulm, Germany; www.ids-imaging.com) fitted with a megapixel lens from Tamron (Commack, NY, USA; www.tamron-usa.com) and an Optotune tunable lens that is mounted on an adjustable stand above an X-Y table. In operation, images at different focal lengths can be captured and be used to create a "superimage" in which every pixel is in focus. Software supplied with the system can also be used to generate a 3D map of the object being imaged.

Third-party software vendors such as HALCON from MVTec Software (Munich, Germany;www.mvtec.com) and Neurocheck from Neurocheck (Remseck, Germany; www.neurocheck.com) can also be used with Optotune's tunable lenses. In demonstrations at the VISION show, Optotune showed how within both HALCON and Neurocheck user interfaces, images at different working distances could be displayed simultaneously by alternating the focal power settings of the tunable lens (Figure 4). By stepping through a series of images under control, HALCON can then stack these images and render a 3D map of the object under test. Neurocheck demonstrated Optotune's EL-10-30 on the head of a robot to re-focus a camera as the robot approaches an object (Figure 5).

Standing waves

Rather than use electro-optical or electro-mechanical techniques to produce tunable lenses, an alternative method that uses an acousto-optical technique has recently been developed by TAG Optics. The company's TAG Lens is a type of gradient index of refraction (GRIN) lens that uses standing sound waves to produce a constantly changing gradient index of refraction within a liquid contained in the lens.

Because variable focusing is based on standing waves within the lens, different frequencies will exhibit different apertures. At low frequencies (such as 70kHz), the effective aperture will be approximately 11mm while at 500kHz and above, the effective aperture will be approximately 1.5mm or even smaller (see "Variable focus lenses uses sound to shape light,"Vision Systems Design, December 2014, pp.11-12).

While the TAG lens is faster (offering sub-microsecond tuning speeds), it is bulkier than those developed using electro-optical or electro-mechanical techniques. Due to its speed, the TAG lens is capable of practical true extended depth of field imaging. Due to this sub-microsecond tuning speeds, the TAG lens can scan 3D volumes in real-time, a feature especially useful in microscopy applications.

Companies Mentioned

Basler

Ahrensburg, Germany

www.baslerweb.com

Cognex

Natick, MA, USA

www.cognex.com

Datalogic

Bologna, Italy

www.datalogic.com

Edmund Optics

Barrington, NJ, USA

www.edmundoptics.com

IDS Imaging

Obersulm, Germany

www.ids-imaging.com

Microscan

Renton, WA, USA

www.microscan.com

MVTec Software

Munich, Germany

www.mvtec.com

Neurocheck

Remseck, Germany

www.neurocheck.com

Opticon

Renton, WA, USA

www.opticonusa.com

Optotune

Dietikon, Switzerland

www.optotune.com

PixeLINK

Ottawa, ON, Canada

www.pixelink.com

SANXO-Systems

Budapest, Hungary

www.sanxo.com

Schneider Optics

Hauppauge, NY, USA

www.schneideroptics.com

TAG Optics

Princeton, NJ, USA

www.tagoptics.com

Tamron

Commack, NY, USA

www.tamron-usa.com

Varioptic

Lyon, France

www.varioptic.com