Systems integration: Vision systems ensure the integrity of packaged products

To ensure the quality and integrity of products packed for one of its customers in the food industry, MCPack (São Paulo, Brazil; www.mcpack.com.br) has developed an automated system to inspect packages of cookies before they are boxed for shipment. Depending on the particular cookie produced, the customer operates between four and five production lines where packages undergo a final inspection before they are placed in cartons for shipment.

In the past, operators visually checked the end seals of each package, that they were folded correctly, and that they were free of tears or holes before they were placed in cartons for shipping. "Inspecting packages before shipment is a critical step, but the manual inspections being used were time consuming and unreliable-it was impossible for workers to check every package," explains Marcelo Cozac, a Director at MCPack.

Collaborating with Teledyne DALSA (Waterloo, ON, Canada; www.teledynedalsa.com), MCPack designed and deployed two different inspection systems to accommodate the packaging requirements of both square and round cookies.

In the first system, five production lines are employed to wrap the cookies. After wrapping, the packages travel along a conveyor and must be inspected. To accomplish this, the packages are illuminated from both sides with two 13.5cm diameter DL194 dome lights from Advanced illumination (Rochester, VT, USA; www.advancedillumination.com). This eliminates any specular reflection caused by the wrapper.

Two BOA smart cameras from Teledyne DALSA, placed on either side of the production lines, are used to capture 1024 x 768 color images of both ends of each package. Embedded Sherlock software then assesses the images of the seal on each end of the packages, checking for the accuracy of folds and seals and for tears or holes. Statistical inspection data from each of the ten cameras is then transferred over a Gigabit Ethernet interface to a Gigabit Ethernet switch and, in turn to a host CPU. This allows operators to monitor inspection results and adjust inspection parameters and tolerances as required.

"Packages are sealed using a heat-based system, so in addition to assuring that the seals are intact, the inspection process also checks for wrinkling in the package wrapper, which can mean that excessive heat was used to seal the package, threatening the integrity of the seal," says Scott Montgomery, senior applications engineer at Teledyne DALSA, who worked with MCPack to design and implement the system. "All packages verified to meet inspection parameters continue down the line for packing and shipment-any package that does not meet specifications is tagged as defective and discarded."

"One of the problems associated with the design of this system was that only one host computer was used to support ten cameras," says Jose Maximo, Automation Engineer at MCPack. "If at any time the IP connection was lost, the operator could not visualize the state of the inspection process."

Because of this, MCPack took a different approach in the development of a second system designed to inspect the seals on similarly packaged products. In this system, deployed across the production lines, two 16.5cm HPD2 dome lights from CCS America (Burlington, MA, USA; www.ccsamerica.com) are used to illuminate both sides of the package as it travels along the conveyor.

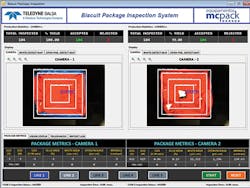

On each production line, images from two Teledyne DALSA Genie cameras with 1024 x 768 color sensors are transferred over a Gigabit Ethernet interface to a Teledyne DALSA GEVA300 embedded vision system. This ensures more efficient image logging and viewing. Here several inspection tasks are performed by Sherlock Professional machine vision software to ensure the quality of the packaging.

Four regions of interest (ROIs) are defined for each of the inspection tasks to be performed. In the first, the outside ROI is used to locate the edges of the package and examine its format. If the package is not deemed to be acceptably square enough, then no other inspection tasks are made. If the package passes this inspection, the system is then programmed to look for any white pixels within the next inner ROI that represent areas where the package has not been sealed correctly. Within the next ROI, any wrinkles that appear in the wrapping are examined. Finally, in the inner ROI, the color image is inspected to determine whether any dark or yellow pixels are present. "This," says Maximo, "then indicates the presence of a cookie and thus can be used to determine an incorrectly wrapped package."

After images are analyzed, pass/fail results are sent from the GEVA300 vision system to a PLC that, in turn, is used to control pneumatic actuators that are used to separate good and bad products.

"With both systems, packages are now inspected at a rate of two packages per second. "A single operator now performs the work of multiple employees who used to be needed to check packages manually," Cozac concludes.