Networked image server simplifies systems integration

By installing a central image sever at its automotive manufacturing facility, a global automaker reduces the cost of image storage and systems maintenance.

Samantha Frost

Automotive transmissions are complex assemblies that can be rendered defective by a single faulty component or incorrect assembly operation. Generally, the cost of repairing and/or replacing a defective transmission can cost hundreds of times more than replacing the defective component itself. If a defective transmission is produced, it is often difficult, and sometimes impossible to determine the root cause of the defect, and more often than not, the transmission plant will be assessed charges related to warranty claims.

To ensure this does not occur, transmission plants have traditionally deployed hundreds of inspectors to manually view each of the parts and validate that the proper assembly operations involved in building the final product have been properly performed. However, this approach is expensive and dependent upon the diligence and attentiveness of inspection personnel.

Over the past decade, transmission plants have transitioned to machine vision inspection for error-proofing the assembly process. One global automobile manufacturer has over 300 machine vision systems in operation, generating 200,000 process images per day, at a plant building 6-speed front wheel drive transmissions. These systems are used to verify each step of the manufacturing processes to reduce manual errors and associated costs.

Such vision systems improve manufacturing quality by identifying problems as soon as they occur to prevent defective parts from reaching the customer. They also provide evidence to prove that the plant was not at fault in many situations where it would otherwise be assessed charges due to a warranty claim. Should a transmission be returned with a warranty claim, archived images are used to determine whether a defective part has been shipped. If the part is defective, detailed information can be displayed to identify the cause of the defect and the engineering department can then be alerted to improve the manufacturing process.

In the past, images were stored locally to each vision system. However, should an individual PC fail, multiple images can be lost. To prevent such incidents from occurring, a central image storage system was installed to save thousands of images per minute with their associated data. This system was also used to provide diagnostics, such as when images are not being stored, or when rejects reach a predefined rate. Operators can now search for, view and export images from any operation in the plant from a single web interface.

Machine vision

The automobile manufacturer that owns the transmission plant makes use of vision systems from Cognex (Natick, MA, USA;www.cognex.com) throughout its manufacturing operations. While differential gears are inspected for correct gear inclusion and tolerances using a Cognex In-Sight 5000 vision system, shifter and clutch plates are imaged by a Cognex In-Sight 5000 to perform measurement and parts presence or absence tasks. (Figure 1a and b).

In the plant, Cognex In-Sight 5000 series cameras equipped with PatMax geometric pattern matching software are used in some inspection and 2D barcode reading applications. In other barcode reading applications, Cognex DataMan 302 image-based ID readers with 2DMax algorithms are used to identify barcodes with damaged Data Matrix codes that may have been degraded or damaged during the manufacturing process. Additionally, the plant employs over 50 Cognex Checkers for identifying the presence or absence of transmission components, such as O-rings and seals.

Storage challenges

The increasing importance of vision inspection makes it essential to retain vision images for use in root cause analysis and to reduce warranty claims. In the past, the transmission plant stored images on PCs scattered through the plant that were used for viewing of local images directly from attached plant floor cameras and also for gathering and storing images for later retrieval. These PCs were expensive both in terms of their initial investment and maintenance costs such as installing new operating system patches, anti-virus updates and repairing hardware failures.

After images were captured, they were transferred via the File Transfer Protocol (FTP) from the camera to the PC. However, there was no feedback loop to determine when the PC stopped collecting images so it was unpredictable whether images were being captured. The dispersed nature of image storage meant that engineers who needed to determine the root cause of a defective transmission had to visit many different PC-based vision systems to collect images. The previous system also did not provide diagnostic capabilities, such as providing alerts when quality was degrading, near the point where defective parts were produced.

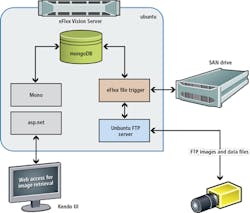

To address this challenge, an eFlex Vision central image storage system from eFlex Systems (Rochester Hills, MI, USA;www.eflexsystems.com) was installed to provide an integrated environment for managing and retrieving process images (Figure 2). The system included an EqualLogic storage server from Dell (Round Rock, TX, USA: www.dell.com) with 12 network interface cards and 48 2TeraByte hard drives with the capability of storing 1,500 images per minute.

Plant floor cameras were then modified within two days to FTP files to the eFlex Vision server. The file name contains the part number, serial number, station ID, camera ID and a pass or fail field. Every time an image is captured by a camera, the camera notifies the image server. If the image server does not receive the image, an alarm is sent, ensuring that any problem in retrieving images is immediately identified and corrected.

Monitoring part quality

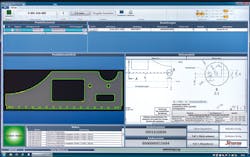

Through a web interface, images can be searched by part serial number, camera, pass/fail, retry count and date/time range (Figure 3). Images can be viewed in varying formats such as carousel, grid or gallery, or exported to a zip file. The server provides real-time information such as hard drive usage, network bandwidth usage, incoming file monitor, non-conforming file monitor, FTP server status and activity monitor.

Additionally, the camera connection status, camera image rate, date and time of last file, and other information is monitored. Real-time monitors can be viewed in a dashboard and configured to generate alarms and warnings. The facility has configured predictive reporting and alarming to statistically monitor reject rates, lighting, part marking grade, part positioning and generate warning and alarm events that notify users of degrading conditions at a particular camera.

In PC-based systems, the Cognex audit message service application that runs on a PC is used to tracks significant camera events. When this audit messaging is enabled, cameras send XML-formatted messages to the audit messaging service whenever a user logs in, changes a job, initiates the camera or changes a parameter. Incorporating this audit message server into the eFlex Vision database will allow operators to be provided with remote alerts if the operating parameters of a vision system are changed anywhere in the plant and to track these changes.

Traditionally, vision systems are periodically tested by running test parts with specific defects through the vision system. Time and money are required to produce and store test parts and downtime is often required to understand how well captured images of the parts will be analyzed by the vision system. These expenses have been avoided with this approach in which images of defective parts can be stored on a server and can be analyzed to test the configuration of the vision system, all while avoiding the expense of system downtime.

Due to the detailed nature of automotive transmission manufacturing, machine vision plays a vital role in ensuring high levels of product quality. Coupling such systems with integrated image storage systems, allows image data to be more effectively managed and any system problems that may occur to be rapidly resolved. When a quality problem occurs or a warranty claim is made, engineers now can quickly find the information they need to identify the root cause of such problems.

Samantha Frost, In-Sight Product Marketing, Cognex Corporation Natick, MA, USA; (www.cognex.com)

Companies mentioned:

Cognex Corp.

Natick, MA, USA

www.cognex.com

Dell

Round Rock, TX, USA

www.dell.com

eFlex Systems

Rochester Hills, MI, USA

www.eflexsystems.com