3D machine vision: 3D vision system verifies glue and gasket beads

The use of bead dispensing in automotive assembly is on the rise. Structural adhesives in automotive body frame and chassis applications allow the joining of dissimilar materials such as aluminum and steel. Likewise, in powertrain and final vehicle assembly, manufacturers are employing a significant amount of Form-in-Place-Gasket (FIPG). In these applications bead volume and placement accuracy is critical to achieve the desired structural integrity and sealing performance.

The challenge, however, lies in applying just the right amount of structural adhesive at the right location. In recent years, machine vision and image processing system designers have taken varied approaches to develop inline non-contact optical inspection systems that provide quality control for the adhesive or FIPG dispensing process.

Two-dimensional (2D) solutions have been developed that can successfully measure bead position and bead width. However, they cannot provide a cross-section profile, which is necessary to verify dispense volume at every position. For example, if vibration causes the dispense nozzle to scuff the part surface and leave only a thin film of bead, a 2D system may not be able to detect the inadequate coverage.

To provide a cross-section profile of the bead, 3D techniques may offer a more suitable solution. In fact, the industry is leaning toward 3D laser triangulation. However, the arbitrary dispensing direction and limited space available around the dispensing nozzle presents a design challenge for developers using general-purposed single-laser line 3D sensors.

One approach has been to implement a motorized single laser line to trail the arbitrary dispensing direction. However, with 400 to 1,000mm/s speeds common in modern high-productivity equipment, motion systems capable of responding quickly and reliably enough to handle sharp dispensing direction changes tend to be complex and costly.

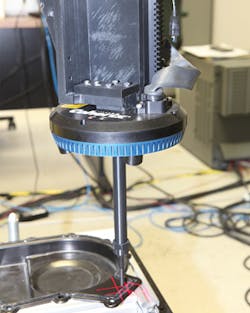

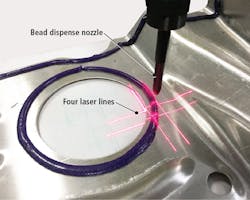

Another option, taken by Coherix (Ann Arbor, MI, USA:www.coherix.com) in its Predator3D structural adhesive and sealant bead inspection system, is to mount multiple laser lines in a compact unit around the nozzle itself. "This ensures inspection of the bead with no blind corner for any arbitrary dispensing direction," explains Dr. Zhenhua Huang, General Manager of the Americas region at Coherix. "By surrounding the dispense nozzle with four lasers that collect 3D profiles in all directions, Predator3D provides a 360° 3D view 400 times per second."

The self-contained system surrounds the dispense nozzle and mounts directly on the robot or pedestal arm. It includes the processor and application software so no additional computer is required. "There is no need for wires going back to a computer for calculation of the bead characteristics," Huang explains. "The compact self-contained design makes installation simple and straight-forward. Just place the part beneath the sensor, start dispensing the bead, and it begins to detect and measure the bead on the part, checking for skips and neck downs that would cause a failure."

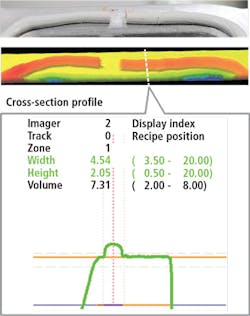

A single Ethernet connection communicates back to either the robot or the Programmable Logic Controller (PLC) and provides plant-network connectivity. During operation, as the sensor head performs the inspection, the actual bead path is displayed on the operator screen. The system provides continuous width, height, volume, and position information.

If skip or neck down criteria are exceeded, it is shown in red to indicate a defect which enables the user to take action according to their process control procedure. A cross section or 3D rendering of the bead can be shown at any point to provide a more detailed visualization of the accuracy of the dispensing process. All 3D data can be saved and exported for offline analysis, report generation and future traceability.

The Predator3D runs on 24-volt DC power, has IP65 environmental sealing and an operating temperature range from 32°F to 113°F.