SYSTEMS INTEGRATION: Vision system improves ice cream production

Producing around 120,000 to 150,000 liters of frozen confectionary per day during summer, Tip Top (Auckland, New Zealand; www.tiptop.co.nz) is New Zealand's largest supplier. To produce these ice cream products, exact quantities of various powdered ingredients such as milk powder are blended with wet ingredients to ensure consistent flavor and texture.

Since large amounts of ice-cream products are produced, numerous 20kg bags of different ingredients are used to make a single batch. Because of this, the exact number and types of ingredients must be checked to ensure that the correct type and amount of ingredients are added to each hopper prior to the mixing process.

"In the past," says David Berry, Owner of ControlVision (Auckland, New Zealand; controlvision.co.nz), "the type and quantity of ingredients added was performed manually. To do so, an operator would identify and count the type of products as they were loaded onto a conveyor. Since this process is prone to human error, it can result in inconsistencies in the final batch. Should this occur, then the whole batch may need to be reworked, costing time and money."

Although bag handling, conveyors, powder handling and mixing systems had been previously installed by Powder Projects (Hamilton, New Zealand), the company realized that a vision system was required to eliminate any human error in the ingredient handling process. Since Tip Top had already contracted ControlVision to install a machine vision system to check lid placement on ice cream products, the company was asked to develop a system to verify whether the correct type and amount of ingredients were added to each hopper prior to the mixing process.

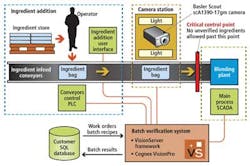

In the development of the vision system, ControlVision installed a 1392 x 1040 Scout scA1390-17gm GigE camera from Basler (Ahrensburg, Germany; www.baslerweb.com) above the dry ingredient conveyor. Mounted with a 9mm Fujinon lens from Fujifilm (Wayne, NJ; www.fujifilmusa.com), images of the complete field of view of each bag are captured by the camera and transferred over the GigE interface to a panel mounted industrial PC/touchscreen from Cybersys Integration Technology (City Of Industry, CA). To illuminate the bags as they move through the inspection station, ControlVision mounted two banks of white fluorescent lights above the camera.

"Although each variety of confectionary may only use approximately ten different types of dry powder product, between 50 and 100 different 20kg bags of ingredients may be used to produce the various varieties of ice cream produced by Tip Top," says Berry. "Because of this, the system must be trained to recognize over 100 different bags. To accomplish this, the company employed the PatMax geometric pattern matching tool from Cognex (Natick, MA; www.cognex.com).

This pattern matching tool is embedded in ControlVision's VisionServer, a machine vision framework and application development environment. This allows functions such as PatMax to be added as a graphical function block diagram in a sequence of functions that capture process, display and control machine vision processes (see "Vision framework supports multiple software packages," Vision Systems Design, February 2012, http://bit.ly/ztDEvU). VisionServer also provides the HMI for operators to train the system to learn new bag artwork as required.

Using the PatMax algorithm, salient geometric features of each particular bag of ingredients are analyzed and stored in the system's database. "Because the system employs the PatMax pattern matching tool," says Berry, "features within images of flat or wrinkled bags of ingredients can be easily detected." In operation, the system then compares these features against the stored database and returns a pattern matching score that ranges from 0-1. If an incorrect ingredient is added, this score will be lower than a preset score and an alarm will be sounded. This alarm will also occur should too many or too few bags of a required ingredient be loaded on to the conveyor.

To monitor the complete production process, the embedded PC/flat panel is also interfaced to Tip Top's supervisory control and data acquisition (SCADA) system. In this way, the operator can monitor whether the correct type and amount of ingredients are being added for a particular batch and the status of the batch verification system.

According to Tip Top Project Manager Brett Dockery, since the new system has been installed, ingredient mixing accuracy has improved dramatically. "Because the camera captures exactly what has gone into the mix, it is much easier to correct any mistakes than in the past, when we had difficulty in determining which ingredient was missing or wrongly added," he says.

Vision Systems Articles Archives