Vision helps robot pack cereal packets

David Langen

Over the past decade, food manufacturers have deployed a variety of automated systems to reduce labor costs and improve the performance of their manufacturing and packaging lines. Many of these systems have performed tolerably without the need for machine vision, which at the outset may have appeared to offer no immediate benefits.

Today, however, system builders who design and supply systems to food production plants are recognizing the advantages of retrofitting vision-based systems to their existing machinery and incorporating vision into newer systems. In doing so, they can further enhance the functionality of production machinery and increase its productivity.

When Canadian systems builder AFA Systems (Brampton, ON, Canada;www.afasystemsinc.com) was called upon to develop a system to package pouches of cereal into cartons, for example, the company initially chose to build an automated solution without the use of a vision system. After appraising the operation of the system in the plant, however, a vision system was retrofitted to the system to improve its effectiveness.

In the original food manufacturing production line, rectangular pouches of cereal were formed, filled and sealed in a pouch filling machine prior to being dropped onto a continuously-moving conveyor. The conveyor then carried the pouches under an electro-optic sensor which counted the pouches before they were sequentially dropped off into a bucket at a loading station. Once a prerequisite number of pouches were loaded into the bucket, the bucket was then indexed to a further station on a servo-driven conveyor. There, a vertical pneumatic plunger confined the pouches in the bucket, after which a horizontal servo-actuated ram pushed the pouches into a waiting carton.

Because the system simply dropped the pouches onto the conveyor after they were filled, however, they were randomly oriented on the conveyor belt. In turn, this caused the pouches to be inconsistently stacked in the bucket at the loading station which led to the pouches being packaged in an unacceptable fashion. Although the issue only affected a small number of packages, the problem was significant enough that the efficiency of the production process was compromised.

Pouch inspection

To overcome this, AFA Systems integrated a vision-based system from Cognex (Natick, MA, USA;www.cognex.com) into the production process. The vision inspection station determines where each pouch is on the conveyor and its orientation. Armed with this information, a custom-built Delta 3 spider robotic pick-and-place system can pick the pouches from the conveyor after the inspection process and correct their orientation before placing them precisely in buckets at the loading station (Figure 1). Having done so, they are pushed into a waiting carton, after which they are sealed and a label is printed and affixed to them.

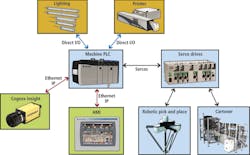

The automated system was built using a set of interoperable hardware and software products from Allen Bradley (Milwaukee, WI, USA; ab.rockwellautomation.com). At the heart of the system is a single 1756-L71 Control Logix programmable automation controller (PAC) programmed using Allen Bradley's RSLogix 5000 programming environment. This controls all the subsystems in the machine, including the camera, lighting, servo drives, Delta 3 spider robot, printer and a cartoner machine which erects the cartons into which the pouches are placed (Figure 2).

In the new system, the pouch-filling machine again drops the randomly oriented pouches of cereal onto a transparent conveyor at a rate of one every 20s. The pouches are then transported at a rate of 3ft/s to the vision station. As the pouches travel through the station, a bank of Patlite CLA white light LEDs bars from Patlight (Torrance, CA, USA;www.patlite.com) situated beneath the conveyor illuminates the underside of the pouches.

An encoder on the servo motor driving the conveyor belt produces a digital output related to the position of the shaft on the motor. This data is fed to the Allen Bradley PAC, enabling it to calculate the distance the conveyor has moved and to trigger a Cognex In-Sight Micro 1050 vision system to capture an image of the pouches on the conveyor after every 50mm of travel.

Blob analysis

Because the pouches are backlit, the pouches obstruct the light from the LEDs, while light is transmitted through the transparent conveyor. Thus, the pouches are imaged as a black rectangular silhouette by the camera while the background image of the conveyor remains white. To process the images captured by the camera, engineers at AFA Systems used a blob analysis tool from Cognex' In-Sight Explorer software library.

The blob analysis tool running on the camera first classifies the pixels in the image as relating to a pouch or to the background, after which the classified pixels representing the pouch are used to form discrete objects. Having done so, the In-Sight Explorer software then determines the location of the pouches on the conveyor and their orientation.

Once computed, this data is transmitted to the Allen Bradley PAC over an Ethernet/IP network where the data is stored in the memory of the PAC. Shift registers in the PAC associated with each set of data are then incremented to enable the location of each of the pouches to be tracked as they move down the conveyor. In doing so, the PAC identifies the point in time at which each pouch has travelled out of the vision inspection station to a pick zone on the conveyor where it can be picked up by the robot pick-and-place machine. The PAC then instructs the robot where to pick the pouch off the conveyor.

One feature of the RSLogix 5000 programming environment is that the motion of the robot can be specified in Cartesian coordinates using standard PAC Logix motion commands. A kinematics feature then automatically transforms the Cartesian coordinates captured by the camera into the coordinate system of the robot.

Positional data is then transferred to a motion control module in the PAC that transmits motion control commands to a set of Allen Bradley Kinetix servo drives over a SERCOS (Serial real-time communications system) noise-immune fiber-optic cable. The servo drives then control the motion of four Allen Bradley MP-Series gear motors from Rockwell Automation. Three of the servo motors move the three arms of the Delta 3 robot while a fourth controls the rotational movement of an end effector attached to the end of an arm through the center of the robot.

Pick and place

The end effector of the robot comprises a cross beam to which two pairs of suction cups are attached. Hoses from the suction cups are connected to supply/release valves on the vacuum inlet of a Model 162510 VADMI-200 vacuum generator from Festo (Hauppauge, NY, USA;www.festo.com). Once a pouch enters the pick zone, a pair of the cups is moved over the pouch as it travels out of the vision inspection station. The robot then positions the pair of suction cups directly above the pouch.

The PAC then instructs the Venturi vacuum generator to open two supply valves on the Venturi generator which provides a vacuum to the cups, enabling the robot to lift the pouch from the conveyor. The robot then performs a similar operation on a second pouch before transferring both pouches over two unfilled buckets while correcting their orientation in flight. Once there, the PAC instructs the generator to release the vacuum in both pairs of cups and the pouches are dropped into the buckets.

To enable a user to monitor, control and display application status information graphically, the PAC is interfaced over Ethernet IP to a single HMI running on a Windows CE-based Allen Bradley PanelView Plus graphic terminal. To allow operators to monitor and view the images of the pouches captured by the camera, AFA Systems also integrated Cognex's VisionView operator interface software into the PanelView Plus system. Once the interface is selected from the HMI screen, it enables engineers at the plant to communicate directly with the camera, allowing them to reconfigure the vision system to accommodate cereal pouches of different sizes.

The adoption of the vision system has some additional benefits. Potentially, it could be used to identify any defective packages, or to detect the presence of features such as bar codes. Although this capability is presently not employed, it would enable the system to reject defective products simply by leaving them on the conveyor, rather than pick them off after they leave the vision inspection station. Rejected products would then simply travel down the conveyor and into a reject bin.

Since its installation in the food production facility, the robot has eliminated the earlier issues caused by inconsistently-stacked pouches and has led to an increase in the efficiency of the packaging operation. Having retrofitted an older machine with the vision system, AFA Systems has since installed four additional systems at the same facility.

David Langen,Electrical Engineer, AFA Systems, (Brampton, Ontario, Canada; www.afasystemsinc.com)

Companies mentioned

AFA Systems

Brampton, ON, Canada

www.afasystemsinc.com

Allen Bradley

Milwaukee, WI, USA

ab.rockwellautomation.com

Cognex

Natick, MA, USA

www.cognex.com

Festo

Hauppauge, NY, USA

www.festo.com

Patlight

Torrance, CA, USA

www.patlite.com