Lasers are now used for everything from cataract surgery to material processing. From military to medical news, the latest science articles are filled with laser technology. But if you look closely at the type of innovation we’re seeing, you’ll find sustaining improvements upon established products, such as increased power, smaller form factor, reduced cost, or improved speed.

For example, the biomedical and life sciences industries are creating a variety of procedures that are less invasive than traditional methods. There is a renewed effort to utilize lasers in defense systems and improve the speed and cost over the past products. Similarly, the high-tech industry is moving towards smaller and more cost-effective components that require laser systems. ESI continues to improve the laser systems in its memory chip repair products while Mitsubishi Electric is using a new fiber laser welding technology that significantly reduces metal spatter.

As many companies focus on sustaining innovations, it opens the door to companies who introduce disruptive innovations that provide new products to a new population of consumers. To capitalize on this opportunity, speed to market is paramount. Research and engineering teams must learn to identify design failures and course correct quickly. Virtual prototyping expedites this process, enabling companies to progress faster with disruptive optical product innovations.

Virtual prototyping enables disruptive innovation

In addition to changing how things are made, lasers can also fundamentally change what is made, but this type of technological advancement is largely uncharted. While 3D printing is starting to explore this, most of the applications of 3D printing involve expediting and reducing the price of customized designs. In other words, most objects that are currently 3D printed could also be created with traditional manufacturing techniques, and therefore are not fundamentally new. For laser technology to also change what is made requires disruptive innovation.

One of the many difficulties in supporting disruptive technologies is that they are likely to underperform in the established market channels. Funding these efforts requires a different focus and structure than that which supports the sustaining technology. These disruptive innovations typically start from a smaller scale experiment or prototype—and this is where virtual prototyping can help.

Most experiments don’t lead to technological breakthroughs, so it is important to move product ideas from napkin to prototype as quickly as possible. Relying on a physical prototype to test each idea often means significant lead times and costly manufacturing resources, and once it’s built, there can be any number of potential sources for error. This involves time-consuming and manual troubleshooting efforts.

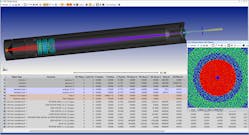

Virtual prototyping, however, enables fast validation and adjustment of product designs. The optical and mechanical design teams work in their own, familiar environments to simulate performance on the entire optomechanical product before creating a physical prototype. It allows them to fail fast and smart during the process—to help uncover which ideas could be a success and which should stay on the napkin. This is especially helpful when aiming to innovate for applications with tight design specifications, as is often the case with laser systems.

Like railroads changed transportation, or the internet changed communication, the next wave of disruptive innovation could be ushered in by laser technology. But in order to get there, managers must provide teams with the tools they need to fail fast and smart during the product design process to determine in which disruptive innovations to invest manpower and budget

To design anything new is a risky undertaking. You have to explore all the ways a design won’t work to find the way it will work. But how can you embrace failure, when you’re in a situation when internal and external pressures demand speedy development cycles? How can you fail faster? Smarter? Better? Improved efficiencies between optical and mechanical engineers are critical to enabling managers and teams to embrace failure on the road to success—especially during six common situations when it can make or break a product.