The Power of Using In-Line Machine Vision to Automate Metrology Systems

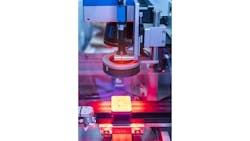

Precision in-line metrology, or measurement, is an important application of machine vision in manufacturing environments.

Using machine vision components, manufacturers can develop in-line setups that measure the dimensions or geometries of products or their features in real time. When thoughtfully designed and tested, the systems produce repeatable and reliable measurements of products during production.

And because in-line vision-based metrology systems operate without physically contacting a part, there is little risk of accidental damage. This is particularly important for products with a lot of delicate structures, such as printed circuit boards.

Related: Keys to Deploying Machine Vision in Precision In-Line Measurement Applications in Manufacturing

In addition to helping manufacturers meet their customers’ expectations for quality, the systems highlight problems in production, so humans can fix issues quickly, saving time and money.

Replacing Manual Processes with Machine Vision

The machine vision-guided in-line process is a substantial improvement over manual processes in which humans take measurements of parts using instruments, such as physical gauges, and then analyze the results to determine if they are within acceptable tolerances.

Still other measurement methods involve some automation but operate in an off-line capacity. For example, specialized coordinate measuring machines (CMMs) use a probe to produce point coordinates of a product, which are used as inputs to calculate measurements. Meanwhile, vision measuring machines (VMMs) use optical components to produce measurements.

Related: Gage R & R Studies in Machine Vision

Solving Problems During System Development

On the other hand, in-line metrology applications using machine vision are not only fast but can acheive 100% inspection rates. Developing these systems is not without challenges, however.

Take the example of part presentation. A system using images only measures what is visible in those images, and this can lead to differences between the measurements taken with an automated vision system versus a manual process, writes Machine Vision Expert David Dechow in a recent article on Vision Systems Design's website. He adds that addressing this issue is best done during the mechanical design phase of developing a vision-based in-line metrology system.

Related: Allocating Tolerances for Vision Metrology Systems

Overcoming this and other challenges is worth the effort. As the speed and resolution of cameras and sensors increases and software becomes more sophisticated, engineers likely will have more options to consider when designing in-line metrology systems that deliver precise and repeatable results.

Have you designed a non-contact in-line metrology system using machine vision that’s delivering results in a production environment? If so, we’d love to hear about it. Drop me a note at: [email protected].

About the Author

Linda Wilson

Editor in Chief

Linda Wilson joined the team at Vision Systems Design in 2022. She has more than 25 years of experience in B2B publishing and has written for numerous publications, including Modern Healthcare, InformationWeek, Computerworld, Health Data Management, and many others. Before joining VSD, she was the senior editor at Medical Laboratory Observer, a sister publication to VSD.