High-speed inspection relies on innovations in software and open standards

A discussion with Neil Cronin of Zynergy Solutions

NEIL CRONIN is business development manager for Zynergy Solutions (Rochester, NY, USA; www.zynsolutions.com) and has held sales, sales-management, and marketing positions with several machine-vision companies. He has a B.S. in business administration from North Adams State College. Editor in chief Conard Holton talked to him about hardware and software for production-line inspection.

VSD: How is Zynergy using machine vision and automated systems?

Cronin:Zynergy Solutions is a turnkey supplier of high-speed automated inspection and motion systems focusing on applications in the pharmaceutical, consumer-products, and medical-device markets. We use machine vision, motion, and automation products from a host of industry standard suppliers. We have supplied hundreds of automated inspection systems to Fortune 500 companies throughout North America that use our systems to inspect, align, gauge, and identify products at production-line speeds

VSD: How is each OEM component more or less important for the applications that you serve?

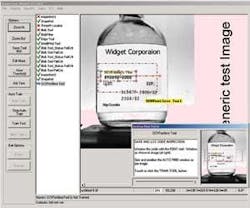

Cronin:Hardware and software must be designed to work together to achieve success for a given vision application. We have found that the software component is the most critical item in any automated inspection system. Zynergy has developed a suite of software modules called Vision Studio that allows us to rapidly prototype and deploy complex vision applications. The modules are built on Microsoft’s .Net framework, allowing us to take advantage of the open-architecture software structure provided by vision-component manufacturers. Vision Studio allows us to integrate into the vision system other open-architecture software packages from suppliers of robot and motion controls, PLC/OPC hardware and software, industrial printers, database packages, and graphing/statistics packages.

Our software suite is the glue providing the customer with a fully automated inspection system that is user-configurable. It provides the capability to define or create an AutoTrain Wizard for ‘show and go’ applications. The wizard is used so that an operator can reconfigure a vision application for product currently running and greatly simplifies the task of product changeover.

VSD: In which areas do you see the most growth? What are users demanding from you in the design of new systems?

Cronin:Zynergy Solutions has experienced tremendous growth over the past two years, and we attribute this growth to the fact that we have narrowed our focus in terms of the markets we serve and the customers that we “partner” with. As a system integrator you are limited by the number of hours in the day and the number of application engineers you have available to deploy systems. We see growth opportunities for our company coming from working with customers who truly see us as an extension of their in-house resources.

To achieve this balance, we ask these questions of new customers and their applications:

- Does the customer understand the technology we are proposing?

- Is machine vision critical to the customer’s ability to produce its product?

- Does the customer have a “written” specification for the application?

- How many production lines will be fitted with vision systems? Does the customer have similar production operations in other locations?

- Does the customer have the technical ability to take ownership of the system once it is deployed and there has been training?

Machine-vision systems must be looked at by the customer as an instrument. As such, the system must be maintained, and engineering and operating personnel must be trained in the proper use of the system. Customers who understand this concept-and are willing to fund it-have proven to be very successful users of machine-vision technology.

Our customers are demanding that the technology we deploy be viable and in use for the next 20 years. We are being asked to provide open systems with industry-standard components that will be supported by the manufacturers for years to come.

VSD: What technologies and components does Zynergy use in these applications?

Cronin:We have recently been named a Cognex (Natick, MA, USA; www.cognex.com) Certified Integrator. In addition, we’ve worked with RVSI Acuity (Nashua, NH, USA; www.rvsi.com) and its predecessor company, Itran, for the past 15 years. Vision Studio currently supports both the Cognex Vision Pro and Acuity Visionscape hardware/software platforms. We have also designed Vision Studio such that other vision hardware/software platforms can be supported in the future, should it be required. We prefer to use the more powerful and flexible PCI-host-based acquisition boards such as the Cognex 8504 or the Acuity 1744 boards for most of our inspection applications. This trend is likely to change with the introduction of faster and more powerful smart cameras.

Increasingly, more of our applications are moving toward the use of megapixel CCD cameras and away from standard 640 × 480 RS-170 formats. The ability to acquire more data at higher frame rates at a lower cost is definitely driving us to use higher-resolution CCD cameras.

Since most of our standard inspection applications involve host-based frame grabbers, we tend to favor commercial PCs running the fastest Intel processors and chip sets we can find. We have extensive experience using industrial PCs, but the decision to use an industrial PC is usually dictated by the customer.

VSD: How do you approach a new application? Do you work with OEMs or other system integrators?

Cronin:We focus on serving the systems needs of large end-user customers. We typically work with the customer’s in-house engineering and instrumentation group or with a third-party machine builder who is supplying a complete automation line to the end customer and has contracted with Zynergy to provide the inspection module.

While we have not done a lot of work with other system integrators in the past, we are looking to ‘shrink wrap’ our Vision Studio package and make the software modules available to other integrators to use as their application deployment platform.

VSD: What could vision equipment manufacturers do to make your implementation jobs easier?

Cronin:The biggest area where vision-equipment manufacturers could assist system integrators is in making their software architecture open and compatible with all of their vision hardware. As the processing power in smart-camera-based systems continues to improve, it would be beneficial to be able to quickly switch applications that were created for PC-based vision jobs to run on the smart camera.

PC-based vendors are doing a good job in making their high-end algorithms run on their smart cameras, but there is no direct link to run applications that were created on the PC with the smart camera. It is a current goal at Zynergy to develop a method whereby Vision Studio can run all of the applications we deploy independent of platform-smart camera or PC.

VSD: What kinds of new applications do you expect to emerge?

Cronin:As machine-vision systems increase in power and decrease in price, we believe that more applications will become available in the markets we currently serve. We also see market segments such as food and beverage opening up and widely adopting the use of machine vision. Smart-camera-based systems that add higher-resolution sensors and the ability to run high-end algorithms will allow us to target cost-sensitive single-camera applications that previously only could have been solved with a PC-based solution.

VSD: How will OEM components targeted toward machine-vision applications have to change to successfully meet those emerging applications?

Cronin:Machine-vision vendors have made tremendous strides in the last 10 years in making the job of deploying vision systems easier. Gone are the days of closed programming environments and proprietary applications. Today end users and system integrators are demanding standardization in both the hardware and software that is made available from machine-vision vendors.

The machine-vision industry has taken advantage of advances in computing power from companies such as Intel and programming standards from Microsoft. To stay competitive and grow, machine-vision companies will need to continue to reinvest in new technology and make sure that their hardware and software is compatible with open standards.