Single-camera dental-imaging system produces 3-D images

Single-camera dental-imaging system produces 3-D images

R. Winn Hardin

Contributing Editor

Several methods exist for collecting three-dimensional (3-D) imaging data, including the use of two cameras to image the same object. In such traditional stereographic platforms, systems integrators use computer analysis to locate a particular feature imaged by both cameras.

Based on the known distance between the two cameras and the angle between them, the computer determines the x, y, and z coordinates and generates a 3-D model of the object.

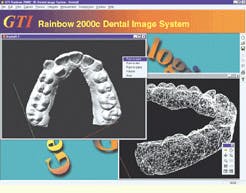

Rather than use this method in its Rainbow 2000 dental imaging system, Genex Technologies Inc. (GTI; Kensington, MD), with support from the National Science Foundation, Department of Defense, and the National Institutes of Health, has developed a single, 3-D image-capture system that comprises an off-the-shelf, color, three-CCD camera; a PC host; a white light source; and a miniature robotic arm to generate 3-D images of teeth casts (see Fig. 1 and cover). GTI claims that its approach offers a way to collect 3-D data from a single 2-D image at real-time video rates without the use of VME or other dedicated computer hardware.

"More than 3 million casts of teeth are strewn through storerooms, boxes, and file cabinets in the United States alone," says Jason Geng, president of GTI. "To eliminate the need for storing these casts and, at the same time, simplify bridge work and other prosthesis construction, the Rainbow imaging system eliminates the need for storing hard casts and allows dentists to perform dental design using CAD modeling software," he adds.

Color and distance

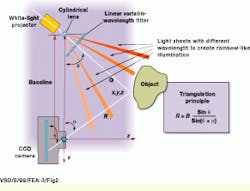

To eliminate the requirements for dual cameras and feature extraction, GTI configures its dental imaging system in a novel triangulation setup (see Fig. 2). Light from a projector is sent through a cylindrical lens arrangement followed by a linear variable-wavelength filter. Much like a prism, the lens separates the light by wavelength into sheets of light, while the wavelength filter refines the split spectrum. Because the distances between the light sheets and the camera and the angle between the baseline and the optical axis of the color camera are known, the color information collected at each pixel can be encoded with angle information.

"During system operation, the color of the projecting light is a spatially and continuously varying wavelength, and color is encoded with a particular light-projection angle. Each pixel of the color camera is associated with a unique ray through the focal point of the camera, so that the angle between the camera axis and the ray is known. Because the distance between the light projector and the camera is fixed, angle-side-angle triangulation can be used to obtain full frames of 3-D range images at 60 frames/s or faster," explains Geng.

In this manner, the Rainbow 2000 imaging system can determine the range distance of each pixel as a function of the red-green-blue (RGB) ratio at each pixel. Says Geng, "Because we look at each pixel individually, the changes in the object`s color don`t matter. The RGB ratio gives the range data for each pixel, and that value doesn`t change."

Because ambient lighting conditions are important in 3-D digitizing, Geng suggests that the amount of light from external sources in the imaging room be limited. Also, because the system depends on the angles and distances between the camera and the placement and operation of a robotic arm to turn the object, each application needs a special setup.

Processor power

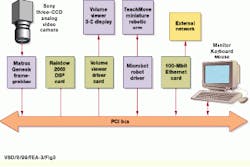

The GTI system uses an analog XC-003 Sony Electronics (Park Ridge, NJ) color video camera containing three charge-coupled devices (CCDs); each device or sensor provides 640 x 480 pixels (see Fig. 3). "We tried digital cameras with the system, but the cost and image-acquisition speed did not seem to be justified," says Geng.

Company system software was developed using Visual C++ running under Windows. It is used to control a commercial frame grabber, such as a Genesis board from Matrox Imaging Products (Dorval, Quebec, Canada), to capture images. Image data are then transferred across the PCI bus to the Rainbow 2000 digital-signal-processing (DSP) board developed by Genex. This card holds six ADSP21060 32-bit floating-point digital-signal processors from Analog Devices (Norwood, MA).

During operation, the DSP board takes the 2-D color imaging data and partitions the image in a format suitable for simultaneous parallel processing by the six digital-signal processors. The 3-D algorithm uses the red, green, and blue values to determine the projection angle associated with each pixel. The range value is then calculated for each pixel based on the geometry parameters of the system, resulting in x, y, and z coordinates based on a triangulation principle. The six high-performance digital-signal processors are used to accelerate the computation to provide full-frame 3-D data in real time.

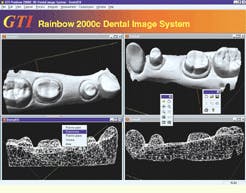

During the processing cycle, the Rainbow 2000 master program directs a robot-controller card to issue control commands to a six-axes-of-freedom robotic arm. This arm was developed by Genex based on a TeachMover five-axes-of-freedom microrobotic arm from Questech (Farmington Hills, MI). The robotic arm moves the teeth cast so that different portions of the cast are placed in front of the camera. Approximately a dozen pictures are taken, processed, and integrated to form a single 3-D dataset of a single cast.

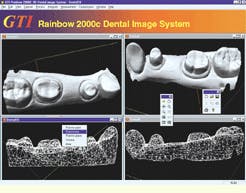

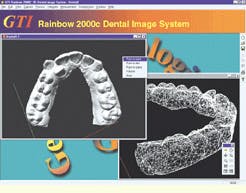

After determining the x, y, and z coordinates for each pixel in all images, the imaging data in native Genex data format are processed by visualization software developed under the Open CL 3-D rendering environment from SGI (Mountain View, CA). This visualization software is a module of the Rainbow 2000 software package. It combines multiple native 3-D datasets into a single 3-D model and saves the result on the PC`s hard drive in STL (stereolithograph), DXF, or the GTI original native data format (see Fig. 4).

Format flexibility

After the 3-D model is generated, the system operator can direct the display of 2-D data with color-coded pixels that represent range data; 3-D data with color-coded pixels that represent x, y, and z coordinates; or 3-D image with a 2-D overlay taken under conventional white lighting. "Instead of RGB or x, y, z, you get both. Other setups use two cameras, but because the data are created by images from the same camera, the need for picture registration is eliminated," says Geng.

The 3-D model can also be displayed on a GTI VolumeViewer, a 3-D display that can accommodate 8.2 million voxels at 2-frame/s refresh rates. This viewer is connected to the PC through a 40-pin cable and a GTI proprietary board based on the Intel i960 single-chip/board computer. A proprietary field-programmable gate array provides addressing and display functions in association with this computer.

The VolumeViewer scans a laser through a moving screen and generates a true 3-D image with realistic depth cues. Says Geng, "By using a volumetric 3-D display, each "voxel," which is analogous to a pixel in a 2-D image, in the displayed 3-D images is physically located at the proper x, y, and z spatial position and emits light from that position to form real volume images in 3-D space. This true 3-D display system provides both physiological and psychological depth cues to humans for perceiving 3-D objects."

The Rainbow 2000 system also contains a 100-Mbit/s network card and an Internet connection. Genex has conducted experiments with the US Navy in which 3-D data files were transmitted via the Internet to a prototype 3-D viewer, similar to the VolumeViewer. Genex has also worked with physicians to develop an imaging database using the Microsoft Access software suite.

The Rainbow 2000 imaging system can help eliminate the need for making 3 million mouth casts per year in the USA alone, as well as reducing the maintenance and upkeep costs of these casts. It can also be used to automate a large portion of the prosthesis-manufacturing processes by importing digital models of the mouth into the machines that create replacement teeth and bridgework. According to Geng, Genex is targeting the Rainbow 2000 system at a variety of other imaging applications, such as facial identification in security systems.

FIGURE 1. Genex Technologies Rainbow 2000 imaging system uses a single analog color, three-CCD-sensor camera; triangulation principle; and a split-spectrum white-light source to determine x, y, and z information from a 2-D image. This process is then manipulated to produce three-dimensional images of teeth casts by the use of three-dimensional computer-aided-design software.

FIGURE 2. To perform 3-D imaging using a single camera and a light source, the projected white light passes through a cylindrical lens and a linear variable-wavelength filter. Wavelength information is then encoded with angle information based on a triangulation principle. The formed light reflected from the object is then digitized and used to extract 3-D data.

FIGURE 3. Dental imaging system comprises an analog color CCD camera, a frame grabber, a special digital-signal-processing board, a custom robotic arm, and a host computer. It can operate either as a standalone system or can be connected via the PCI bus to a local network. A special 3-D VolumeViewer is optional.

FIGURE 4. Based on processed dental imaging data, the system operator can display the original imaging data; the color-coded 2-D image that represents range data per pixel; a color-coded 3-D representation that represents x, y, and z coordinates; or a three-dimensional photo with a true-color 2-D overlay.

Company Information

Analog Devices Inc.

Norwood, MA 02062

(781) 329-4700

Fax: (781) 326-8703

Web: www.analog.com

Genex Technologies Inc.

Kensington, MD 20895

(301) 962-6565

Fax: (301) 962-6555

E-mail: [email protected]

Web: www.genextech.com

Matrox Imaging Products

Dorval, Quebec, Canada H9P 2T4

(514) 685-7230

Fax: (514) 685-2853

Web: www.matrox.com

Questech

Farmington Hills, MI 48335

(800) 229-0018

Fax: (248) 615-0808

SGI Inc.

Mountain View, CA 94039

(650) 960-1980

Fax: (650) 961-0595

Web: www.sgi.com

Sony Electronics

Park Ridge, NJ 07656

(201) 930-1000

Fax: (201) 358-4058

Web: www.sel.sony.com