Imaging system guides dental-student actions

Imaging simulation system enables student dentists to practice drilling teeth without a live patient.

By Joe Hallett, Contributing EditorElectronic imaging technologies and products are dramatically impacting the dental industry. They are managing massive amounts of data and images, establishing new dental techniques, and enabling quality patient care, cost control, and privacy rights for dental professionals. Dental imaging not only aids in the treatment of disease, but also helps doctors, surgeons, and orthodontists in planning and implementing cosmetically acceptable reconstructive processes. In addition, vision-guided tools help both students and dentists to practice, administer, and improve meticulous procedures in realistic tooth simulations within a patient's mouth.

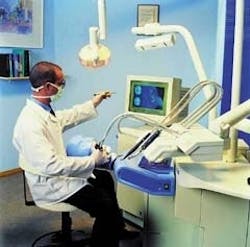

FIGURE 1. Workstation includes a dental chair, a mannequin with plastic teeth, a tracking camera, two computers, a display, and associated electronic and electromechanical parts. This setup provides a realistic training environment for dental students. (Photo courtesy of DenX America)

Dental work relies greatly on the skill, training, and experience of the individual dentist. Accordingly, dentists in training need practical "preclinical" experience before they can begin to work with patients. In the past, dummies such as head-on-a-stick mannequins were fitted with plastic teeth for student practice. In some dental schools, patients were encouraged to obtain free dental work done by students. In both cases, students had to wait their turn with an instructor to grade performance. The general result was lost training time and effort.

Dentists have now turned to the imaging industry for a system solution to the training logjam in the form of a dental simulation system—one that could provide student dentists with repetitive practical experience in drilling patient's teeth without requiring immediate personal attention by an instructor. To meet this demand, DenX America Inc. (Tanzana, CA) developed the DentSim system (see Fig. 1).

FIGURE 2. Computer screen shows the position of the dental tool in the simulated patient's mouth, isolated views of the "working" teeth, and pushbuttons for accessing data and controlling tasks.

This system exploits the proven technology of image-guided surgery. It allows students to "drill" into the space occupied by a computer-generated three-dimensional (3-D) image of a tooth. As tooth material is removed, the displayed image shows the visible result. The system also stores precise data—sizes, shapes, and angles—that can be immediately compared with standards or stored for later evaluation.

Sholomo Lehavi, president and chief executive officer of DenX America Inc. and a professional dentist, says, "Historically, a dental student works in a laboratory and sits at a bench. The student attaches plastic jaws to a stick and drills acrylic plastic teeth that are the same size as real teeth. In our system we use the same dental forms, but place them inside a simulated patient's (mannequin's) head that can be freely moved. The student can open the simulated mouth and place the head in a realistic position. The system tracks both head movement and the (student's) hand position. Because the system knows the precise position of the head and dental handpiece, it can calculate the cutting actions and mathematically subtract material from the tooth structure.

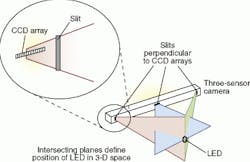

FIGURE 3. The tracking camera provides three CCD arrays that detect the angle of arrival of light from multiple LEDs on the mannequin and the drilling handpiece. It captures the precise position and angle of the mannequin's head and teeth. The derived data are processed by two computers to calculate the actions of the dental handpiece.

The resulting color graphic is highly accurate during tooth cutting. The system continuously tracks what the student is doing in the mannequin's mouth and quickly feeds back information to the student. The student doesn't need an instructor to evaluate whether the angle between the floor and wall of the tooth cavity is correct. The system has proven to be accurate and objective."

Stored data can be replayed and viewed at any time by students and instructors and allows changes in lighting, viewing position, and magnification (see Fig. 2). "The system provides a view that you can't get with an intra-oral camera," says Lehavi. "The student can work on a simulated tooth that is 5 to 8 mm in height. To drill in preparation for filling, the student works in a volume of about 2 to 5 mm in height, 2 to 3 mm in width, and 1 to 3 mm in depth. Accuracy of the simulation system is ±150 µm."

Nathan Persky, vice president for research and development at DenX, adds, "The optical tracking subassembly, which is built by IGT Leibinger Division, Stryker Corp. (Boulder, CO), tracks the motion of 16 light-emitting diodes (LEDs) on the handpiece (drill) and seven LEDs on the mannequin for reference purposes. It calculates the position of the teeth and the geometrical relation between the teeth and the angle of the tool." The IGT subassembly has been modified by DenX by adding circuit cards to enhance accuracy and stable calibration. It consists of a three-sensor camera and a host computer that performs image-processing and control functions (see Fig. 3). Each sensor is a linear CCD array that is positioned behind a perpendicular slit aperture.

The dental handpiece is fitted by DenX with a special handle to house the 16 LEDs (see Fig. 4). "The LEDs are multiplexed so only one at a time is illuminated," says Persky. "Tracking the dental tool requires a minimum of three LEDs that are visible to a camera by line of sight, but four are used to get higher accuracy."

FIGURE 4. The LED-equipped handpiece is composed of a handle equipped with 16 LEDs for use as a dental tool. As drilling progresses using the dental drill tool, the triangulation data obtained from the LEDs convey accurate information about the amount of material removed by the tool.

When light from an illuminated LED strikes the array, it appears as a single dot (see Fig. 5). The three CCD arrays therefore perform three measurements that define the point of origin in 3-D space. According to Ivan Faul, IGT technology vice president and chief engineer, "The camera bar is 300 mm from end to end with a 200-mm spacing between (outboard) sensor arrays. Its working volume is a 300-mm-diameter sphere, centered 750 mm from the center array to center of the sphere."

A data stream of six parameters (x, y, z, roll, pitch, and yaw) is produced by the scanning system by repetitive triangulation of LED positions as the dental tool is moved. These parameters are passed as ASCII data to the DenX computer for 3-D rendering. Based on these data, drilling places are calculated—in real time—and represent "material" removed by the dental handpiece. The volume of removed material is subtracted from the original model of the tooth, creating a realistic simulation of the tooth as it is being drilled.

FIGURE 5. DentSim imaging simulation system establishes a 3-D model of a mannequin's teeth using a three-sensor camera. This camera and a host computer perform image-processing and control functions (see Fig. 3). Each sensor is a linear CCD array that is positioned behind a perpendicular slit aperture. The system calculates the tooth material removed by the motion of the LED-equipped dental tool using data from the optical scanning subsystem.

"We recalculate this model about 10 to 12 times per second," said Persky, "but the real issue is not real time (display). The most important part is evaluation after drilling is finished. The system calculates the student's work and compares it with an expert system model, giving feedback about mistakes, such as in cross section (too deep) or not at the correct angle. The student gets an accurate and detailed report on accomplished work. Additional practice work can be repeated without an instructor's help."

Every unit (student station) uses two computers and custom software. One computer—a "headless" PC—is part of the IGT tracking subsystem. The other computer is provided by DenX for processing the positional data stream, rendering 3-D images, and calculating differences between actual and ideal results. It also controls on-screen displays and menus. Says Persky, "We use Windows-based PCs. System software is written in C++ using RenderWare development tools from Criterion Software Ltd. (London, England)."

A DentSim dental simulation system typically costs $70,000. Installing several networked systems in a classroom could cost $2 million to $4 million. However, more than 20 dental schools worldwide have purchased these systems, including seven in the United States, according to Lehavi.

Early next year, DenX expects to begin marketing its Image Guided Implantology (IGI) system for planning and installing dental implants. The implant process requires an accurate placement of titanium supports in the patient's jaw, upon which artificial teeth are mounted. The DenX system uses computed-tomography scans to map the patient's jaw. Software helps to define where to place the implants, and image guidance assists the dental surgeon in finding where to drill the jaw in preparation for installing the tooth supports. "The DenX IGI surgical station allows a dental surgeon to place screws accurately, avoiding key nerves," says Faul. "The guidance system allows surgeons to drill straight and not too deep."

Company InformationCritetion Software Ltd.London, EnglandWeb: www.csl.comDenX America Inc.

Tarzana, CA 91356

Web: www.denx.com

IGT Leibinger Division,

Stryker Corp.

Boulder, CO 80301

Web: www.imageguided.com