Matrix Vision at VISION 2016: How machine vision software enhancements improve our cameras

One of the numerous conversations I had at VISION 2016 was with Dietmar Unser, Marketing Manager at Matrix Vision. During the interview, we talked about Matrix Vision cameras and the camera development process, the company’s software, and potential market growth drivers.

First, Unser told me a bit about some of the cameras that the company is most excited about, including the mvBlueGEMINI smart camera, which is available in a standard version, as well as the mvBlueGEMINI-Ident and mvBlueGEMINI-Inspect models. The mvBlueGEMINI-Ident is designed for reading texts and codes, including barcodes, 2D codes, or QR codes, while the mvBlueGEMINI-Inspect is used for inspecting objects and is able to find, check, and measure objects in inspection tasks. mvBlueGEMINI smart cameras are based on the 1.3 MPixel e2v EV76C560 CMOS image sensor, which features a 5.3 µm pixel size, and also features an FPGA/SoC with Dual Core Cortex-A9.

Products such as these, as well as custom products, explained Unser, are developed through close interaction with customers.

"We always get a lot of input from customers. Customers ask for specific solutions and we develop these, but we also develop custom solutions that help us to identify new products and ideas," he said.

He then discussed his company’s camera software, and how this was developed for a specific reason.

"With the Gemini, customers asked for easy-to-use software that could be used without programming. We looked at the available software and weren’t comfortable enough, since many customers don’t have enough programming experience."

As a result, Matrix Vision developed Impact Configuration Studio, which is based on MVTec HALCON functions with a powerful framework built around it to make it easier to use, according to Unser.

In terms of the markets that Matrix Vision serves, Unser mentioned a number of "traditional markets," including machine vision and life sciences, but also noted some areas of potential growth as well. These included logistics and robotics.

In logistics, for example, there are a number of applications that require many cameras, such as a conveyor belt with numerous packages with codes that need to be read. Unser explained that this requires high-resolution, high-speed cameras for analysis.

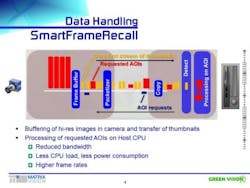

"Customers had asked for an intelligent solution with less hardware and processing power, and as a result, we developed SmartFrameRecall."

This feature, which is part of the mvBlueCOUGAR-XD camera firmware and was demonstrated at the show, enables a camera to capture high-resolution images and send them to a small, embedded PC for storage in the frame buffer while sending preview images with reduced resolution. This requires lass bandwidth, as the tool only looks for potential defects or areas of interest in the thumbnails, and can pull up a high-resolution upon request if further analysis is necessary.

The benefit, of course, is that it can be run with less bandwidth on a smaller embedded PC. Unser provided an example of a recent system he saw installed for inspection purposes. In this system, eight industrial cameras were connected to eight separate PCs, with a ninth PC being used for image processing. With SmartFrameRecall, only one single PC is necessary, which opens up new applications in embedded imaging.

Concluding our conversation, Unser told me that overall, the market is strong, and that new application areas only help it to grow.

"These new ways to use image processing make us think it is a strong, growing market," he said.

View more information on Matrix Vision.

Share your vision-related news by contacting James Carroll, Senior Web Editor, Vision Systems Design

To receive news like this in your inbox, click here.

Join our LinkedIn group | Like us on Facebook | Follow us on Twitter

Learn more: search the Vision Systems Design Buyer's Guide for companies, new products, press releases, and videos

About the Author

James Carroll

Former VSD Editor James Carroll joined the team 2013. Carroll covered machine vision and imaging from numerous angles, including application stories, industry news, market updates, and new products. In addition to writing and editing articles, Carroll managed the Innovators Awards program and webcasts.