EyeVision Develops Inspection Tool for Fastener Threads

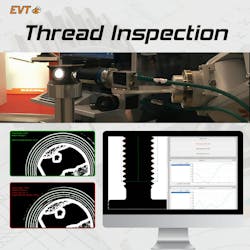

Software developer EyeVision (Karlsrue, Germany) has added a tool to its machine vision software suite that detects defects in fastener threads. The tool, Thread Inspector, is designed for easy integration.

In industries such as automotive, electronics, and aerospace, the quality of threading is critical. Indeed, there is no room for error when it comes to items such as fasteners, bolts, and other such threaded parts; even very minor flaws can render them useless, notes EyeVision CEO Michael Beising.

“For example, in the automotive industry, incorrect threads during engine production can cause serious damage or even render the engine unusable,” Beising says. “In this case, thread testing is very helpful in avoiding costly rejects.”

Traditionally, inspections of such items, especially the threading in fasteners, have been performed by human inspectors. However, the quality of inspection is often dependent on the skill and experience level of the individual performing the inspection, as well as other factors, such as overall working and environmental conditions. Consequently, the manual inspection process is error prone.

Thread Inspector is designed so that an integrator can develop a high-speed automated inspection system that not only handles the mundane and repetitive aspects that can make manual thread inspection more difficult for human inspectors, but also performs the inspection with 100% accuracy, as well as store, curate, and distribute inspection results.

Designed for versatility and easy integration, the software supports 1D, 2D, 3D, thermal, and hyperspectral imaging and features AI and deep learning algorithms as well, Beising says. The software is hardware-independent, so it will work with virtually any camera, provided it has at least 2 MPixel resolution. Thread Inspector inspects each thread by segmenting the images of the threads into sections to measure such key details as pitch distance (the distance between the same point on two adjacent threads), thread angle (the included angle between a thread’s helix and a plane perpendicular to the axis of the thread), major diameter (the largest diameter of a thread) and minor diameter (smallest diameter of a thread). Because the software is essentially turnkey, hardware components are chosen based on what is most appropriate for the inspection system, Beising says.

To Learn More:

Contact: EyeVision

Headquarters: Karlsrue, Germany

Product: Thread Inspector

Key Features: Turnkey, supports 1D, 2D, 3D, thermal, and hyperspectral imaging, AI/deep learning algorithms

What EyeVision says: View more information on Thread Inspector

Share your vision-related news by contacting Linda Wilson, Editor in Chief, Vision Systems Design.

About the Author

Jim Tatum

Senior Editor

VSD Senior Editor Jim Tatum has more than 25 years experience in print and digital journalism, covering business/industry/economic development issues, regional and local government/regulatory issues, and more. In 2019, he transitioned from newspapers to business media full time, joining VSD in 2023.