Novel broadband LED enhances hyperspectral imaging applications

Marc Landman and Florian De Oliveira

In hyperspectral imaging, images can be acquired by sequentially allowing narrow wavelength bands of light from a sample to hit a camera’s image sensor. By selecting the appropriate wavelengths, these images allow the assessment of product quality and the detection of contaminants and foreign material based on chemical composition, something not possible using traditional machine vision. Like conventional imaging techniques, hyperspectral imaging also requires the selection of appropriate illumination for high-quality results.

Hyperspectral illumination requirements

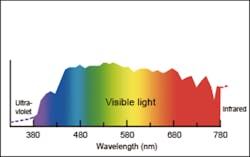

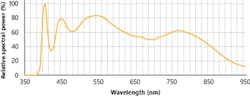

Key to hyperspectral illumination is having as homogeneous emission as possible over the entire wavelength range of interest from a point source to ensure that all wavelengths are generated from the same physical location. For visible to near infrared (NIR) hyperspectral imaging, the wavelength range is 400 to 900 nm. The ideal illumination source would be sunlight (Figure 1), but this is not practical for machine vision, so a black-body radiation source in the form of a tungsten halogen light source has been the most commonly used solution to date.

While halogen light sources generally have good uniformity of emission over the wavelengths of interest, the lights have relatively poor emission in the blue spectral range and a large proportion of the energy emitted lies outside the wavelength region of interest. Wasted energy generates excessive heat, meaning the lamps must be cooled or equipped with suitable heat sinks. This adds cost, complexity, and can lead to significant integration challenges in production line applications due to the bulky size of the enclosures. Additionally, challenges exist related to stability— an essential requirement for reproducibility of measurements in machine vision—and short lifetimes which have implications on operating and maintenance costs.

Further challenges include the fact that European Union environmental regulations may result in these types of lamps being banned going forward, and that many industrial imaging applications also require strobed illumination to eliminate the effects of product movement, but halogen lamps cannot be pulsed.

LED lighting

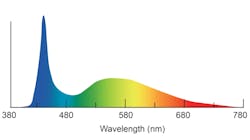

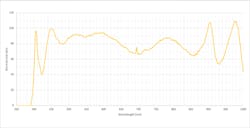

While LED illumination has largely replaced other illumination methods in most machine vision applications, limitations exist for hyperspectral imaging. In hyperspectral imaging applications, the source must cover the entire spectrum between 400 and 900 nm and provide uniform illumination across the wavelength range. White LEDs do not necessarily offer uniformity, as they have a large peak in the blue region of the spectrum while the red components are very weak (Figure 2). Additionally, the CMOS image sensors used in VIS-NIR hyperspectral imaging cameras typically offer sensitivity between 400 and 1000 nm, but the conventional white LED has little output beyond 700 nm.

One alternative approach involves using multiple monochromatic LEDs in a single illuminator to cover the required wavelength range. Dealing with multiple LED sources compromises between spectrum and uniformity because the bandwidths of classic monochromatic LEDs are narrow, making it nearly impossible to produce a homogeneous high-performance area hyperspectral light using the number of narrow-band LEDs required. In fact, such a setup is more of a multispectral solution, where the available wavelengths are limited to those of the LEDs chosen. Until now, the only practical way to integrate enough LEDs for hyperspectral lighting is to combine them into a line scan illuminator. This, however, creates spatial inhomogeneity since the light from the individual LEDs arrives at the sample from different angles, depending on the position of the LED in the line.

A new LED solution

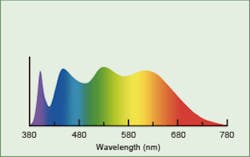

Natural light LEDs, such as those developed by CCS Inc. (Kyoto, Japan; www.ccs-grp.com), have a high color rendering index, meaning they generate a smooth continuous spectrum across the wavelength range with a similar spectral distribution to sunlight (Figure 3). Although these offer more uniform spectral distribution than conventional white LEDs, the usable wavelength range is still not sufficient for hyperspectral imaging. To address this, CCS and its subsidiary EFFILUX (Les Ulis, France; www.effilux.com) have developed a novel single LED illumination source that offers a tunable continuous spectrum from 400 to 900 nm and can be produced in any form factor, including projector, bar, ring, and backlight for line scan or area scan hyperspectral imaging applications.

A key differentiator between the CCS design and other broadband LEDs is that the proprietary LED is based on a single chip design. As a result, this point-source type design creates better spatial and spectral uniformity than could be achieved using multiple LEDs. Since the LED is a single-point source, all wavelengths come from the same spatial origin, meaning there are no wavelength-dependent angular absorption effects. The ability to tune the light within the available spectral range to tailor the light output to application requirements makes it so that the system is not limited to fixed-output wavelengths as is the case for multispectral imaging. In addition, the hyperspectral LED can be strobed if required and multiple LEDs can be mounted on a single PCB if increased output intensity is needed.

Many organic materials have important absorption bands in the NIR region of the spectrum and CMOS sensors still have sensitivity to 1000 nm. Light output from the new hyperspectral LED falls away quite rapidly past 900 nm (Figure 4), but this can be compensated for through the addition of two more LEDs with output at 910 and 970 nm respectively to give increased output intensity between 900 and 1000 nm, as shown in Figure 5. Featuring just three LEDS, the new product can integrate into a variety of enclosures, as shown in Figure 6.

Systems integrators may benefit from using such an LED instead of halogen or multiple LED-based solutions, while having the ability to choose the right type of light or form factor for a particular imaging requirement. Additionally, because CCS manufactures the hyperspectral LED, the company can tune the spectrum to the application requirements and control LED cost.

Practical applications

Existing tungsten halogen hyperspectral illumination sources have considerable operational challenges, such as heat dissipation, poor energy efficiency, continuous only output, and have difficulty achieving high spatial uniformity due to lamp size and optics. Because of this, it is often not possible to build these lights in the form factors most frequently needed for automated hyperspectral imaging.

The availability of new hyperspectral LEDs in a variety of form factors opens new opportunities across many applications and industries, including medical imaging and diagnostics, environmental monitoring, forensics, food and pharmaceutical analysis, food sorting and quality grading, biotechnology, recycling, bank note inspection, and chemical analysis. For instance, hyperspectral imaging has demonstrated success in the quality assessment of fruits and vegetables, where halogen sources might be unsuitable due to the excessive heat radiated and many other limitations.

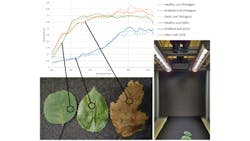

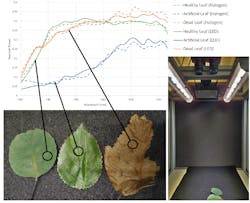

In an experiment conducted with healthy, artificial, and dead leaves with a spectral distribution in the 690 to 960 nm range, the new LED paired with an MV1 series hyperspectral camera from Photonfocus (Lachen, Switzerland; www.photonfocus.com). The setup proves capable of delivering high spatial and spectral uniformity comparable to halogen without such drawbacks as lifetime, heat dissipation, stability, and environmental issues (Figure 7).

Marc Landman is a Senior Technical Advisor at CCS America and Florian De Oliveira is a Business Development Engineer at EFFILUX SAS.

Related stories:

Hyperspectral imaging system grades agricultural products

Deep learning and hyperspectral imaging technologies team up for diseased potato identification

Multispectral and hyperspectral cameras expand the scope of industrial imaging

Share your vision-related news by contacting Dennis Scimeca, Associate Editor, Vision Systems Design