Thermal imaging: Learn the limits of elevated body temperature screening

Markus Tarin

As government and corporate America develop post-COVID-19 action plans for responsibly reopening the country, some businesses are scrambling to keep up with the demand for thermal cameras, which many believe can help identify novel coronavirus cases via elevated temperature detection

During the SARS outbreak in 2002, the same demand occurred, albeit on a much smaller scale and mainly in Asia. As with most infectious diseases, people want to keep it from spreading. Fever represents a common COVID-19 symptom. Sometimes a person with a fever may not feel particularly sick and may still attempt to travel or come to work. Afraid of being booted off a plane or sent home, the motivation for self-reporting a potential illness quickly outweighs the consequences. Technology offers an attractive route for companies looking to screen for sick people. Companies feel severe economic pressure to reopen their businesses to survive, while other essential businesses fear that a company outbreak could bring them to a screeching halt, as has happened in the food and restaurant industries.

Several methods to check somebody’s temperature exist (Figure 1), but the larger the company, the less practical it becomes to have a medical professional use a handheld thermometer to screen everyone entering the building. This method is somewhat invasive and not conducive to social distancing guidelines, which is why non-contact thermal imaging has emerged as a popular alternative.

Thermal camera solutions pop up like mushrooms as demands soar. MoviTHERM has counted 52 new solutions just in the past eight weeks in the US. Many of these are brand new startups, while others simply rebrand mass produced existing, commercially available thermal cameras. Offerings range from cell phone attachments with low resolution thermal cameras to dual view thermal and visible cameras with built in artificial intelligence for tracking people in a crowd. Marketing literature and demonstration videos from such companies may impress the panic buyer looking for a way to keep their workforce safe. What used to take engineers weeks and months of research is now being decided in 24 to 48 hrs. Even Amazon bought 1,500 thermal cameras for $10 million from a US Government-blacklisted Chinese supplier.

How hard can it be? A thermal camera is a thermal camera! Or is it?

If that was the case, why do the prices of these cameras vary from $400 to $40,000? It isn’t just the thermal camera that matters, it is how it is being applied to the application. Measuring elevated body temperature happens to be a rather complex application once you peel back the layers. After all, this does not involve simply measuring the temperature of a piece of steel but measuring the temperature of living beings under various conditions. Throwing a startup company together and hiring a few software developers to get an image out of a thermal camera is missing the point entirely. Thermal imaging uses some rather complex physics and involves optics, thermodynamic laws, emissivity, atmospheric variables, thermal drift compensation, infrared radiation, reflection, transmission, and in the case of this application, a slew of physiological effects of the human body.

Related: Choosing a camera for infrared imaging

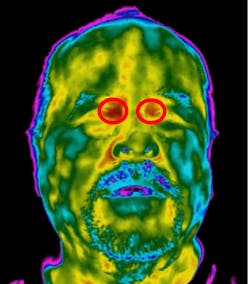

Thermal cameras cannot detect a fever or diagnose any disease. A thermal camera can only measure the infrared radiation emitted from the first surface it encounters. When pointed at a face, this first surface happens to be the surface of the skin. However, when examining the thermal landscape of a human face, one will quickly notice the complexities. Additionally, such measurements vary tremendously from individual to individual.

Accurate measurements

Scientific research shows that most of the facial skin temperature is not even that closely correlated to the body’s core temperature. The human body thermoregulates its core temperature using a complex biological closed-loop system. It either exerts excess heat, conserves it, or maintains equilibrium, and it does so as a survival mechanism. This regulation causes the skin temperature to vary based on environmental condition (passive heating or cooling due to exposure to the elements), physical exercise, or other biological processes.

Studies show that the inner canthus (tear duct region) represents the most accurate part of the face when it comes to optical temperature measurement (Figure 2). The inner canthus is only about 5 to 7 mm in size. Using a thermal camera, the inner canthus needs to be covered with enough pixels for an accurate measurement. The projected pixel size for the inner canthus area needs to be around 1.5 mm/pixel or better for best results.

Camera resolution vs. image size

Unlike typical machine vision or surveillance cameras, thermal cameras have low pixel resolutions. The most common resolution for thermal cameras is 320 x 240 or 640 x 480 pixels. Using the 1.5 mm/pixel figure from above makes it possible to calculate the field of view size of the thermographic measurement setup for measuring elevated body temperature.

For a 320 x 240-pixel detector, the horizontal field of view is therefore 320 pixels / 1.5 mm per pixel = 480 mm [18.9in.]. Other common detector resolutions and the recommended image size for inspection can be seen in Table 1.

Crowd scanning solutions

Based on the resolution criteria discussed above, crowd scanning solutions cannot produce the desired results. Artificial intelligence also does not help to bend physics and has no impact on human physiology. In addition to the pixel resolution problem, a second issue exists that impacts the accuracy of a crowd scanning camera – depth of field. In a crowd setting, individuals will be present at different distances to the camera. Not only does this change the projected pixel size, but it changes how well the pixels are in focus.

Related: 3D scanners and printers enable rapid reusable N95 mask production

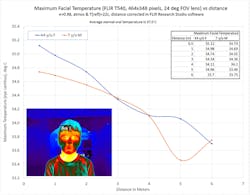

Figure 3 shows an accuracy test of a thermal camera with 464 x 348-pixel resolution with 24° optics. The test subject’s oral temperature was confirmed with a clinical grade thermometer prior to the test and determined to be 37°C [98.6°F]. Measurements were taken of both subjects starting from 0.5 m [1.64 ft] to 6 m [19.7 ft]. The maximum skin temperature (inner canthus) was recorded and graphed. This experiment shows a significant temperature drop with increase of distance. The camera used is a higher end thermal camera – the FLIR Model T540. Performing the same experiment with a lower grade and lower resolution camera will undoubtedly yield worse results.

Camera accuracy

Absolute accuracy represents an even bigger issue with these types of cameras. Such cameras are based on the same measurement principle and use a microbolometer type detector. These detectors do not capture photons, but directly measure infrared radiation. Each pixel comprises a small MEMS structure and represents a small temperature dependent resistor. The downside of these detectors is extreme temperature sensitivity. The slightest change in heat causes a bias in the measurement. The same thing happens with infrared optics made from Germanium or other exotic optics. These effects, along with noise equivalent temperature difference (NETD) create the error budget of these cameras. An achievable absolute accuracy specification is typically around +/- 2°C. Controlling the temperature drift to any tighter tolerances requires a sophisticated active heating and cooling system inside the camera, which would be cost prohibitive.

Some manufacturers claim their cameras can achieve an accuracy of +/- 0.5°C. The question people should consider is how the cameras measure accuracy. One way of achieving this would be to point the camera at a reference black body and rapidly take successive measurements before the camera drifts. Doing so would be cheating if the companies omit their method of determining accuracy, however.

Black body method vs. relative difference

Two legitimate methods for measuring elevated body temperatures exist. One employs a calibrated reference source (or black body, Figure 4) and the other uses a baseline population to create an average for outlier detection. Using a black body allows the camera or software to calibrate out the long-term drift and correct the absolute temperature of the measurements to better than +/- 0.5°C. For this to occur properly, the black body must be visible in the field of view of the camera at the same working distance as the subject.

The other method does not require a black body and makes use of the repeatability of the thermal camera, although combining the two methods would be ideal. In the relative difference mode, 10 known healthy individuals present to the camera or screening system. Their maximum facial temperatures are taken to build an average baseline temperature. Now all subsequent subjects are measured and compared against that baseline reference. This creates an outlier detection. The baseline needs to be updated throughout the day to compensate for environment changes like temperature swings.

Related: Shortwave infrared enhances machine vision

What is a black body?

A black body or calibrated reference source is an actively, temperature-controlled device. Black bodies typically provide a reference source for calibrating thermal cameras and other optical temperature sensors, such as pyrometers. These devices consist of an active surface with a special high emissivity coating, an internal temperature sensor and a closed loop (PID) temperature controller. Some black bodies have an adjustable temperature controller, simpler devices have a single, fixed temperature. For special high temperature applications, there are cavity style black bodies available. The name black body comes from physics – black body radiation. The name was given because the idealized version of a black body absorbs all radiation of all wavelengths. However, some practical limitations to this exist. A perfect black body would have an emissivity value of 1. However, most good black bodies only achieve an emissivity value of 0.98 or lower.

Planck’s law describes black-body radiation. The higher the radiated energy, the shorter the wavelength. This phenomenon can be seen when heating up a piece of metal. The heat cannot be seen until it reaches a certain energy level, then the piece of metal starts to faintly glow red. As the energy further increases, red becomes orange, orange becomes bright yellow. The wavelength shifts from the infrared region into the visible region and becomes perceptible by human vision (400 nm to 700 nm).

Rules and regulations

In the US, the Food and Drug Administration (FDA) deems this a medical application. As such, cameras need to have a 510k approval (bit.ly/VSD-510). Any customer or vendor using a camera without such an approval risks being subject to recalls and/or stringent corrective action measures, which is exactly what happened during the SARS outbreak. Although the FDA recently issued a non-binding and temporary guideline to ease their regulatory overview, the 510k ruling is still in place and may be enforced at any time. Besides the FDA, there is also a heightened risk of civil litigation for companies using a non-approved camera.

In conclusion, the most important questions to ask a potential supplier are:

- How long has your solution/camera been on the market?

- Has your solution been used successfully during the SARS outbreak?

- What is the ideal distance to subject during screening?

- Does your camera have a 510k approval and can you send it me?

Markus Tarin is the President & CEO of MoviTHERM (Irvina, CA, USA; www.movitherm.com)