3D vision systems provide quality control at copper refining plant

Manually inspecting thousands of sheets of metal per day on multiple production lines running 24 hours a day presents a multitude of quality control challenges. An automated 3D inspection system, on the other hand, can keep up with the steady flow of product and provide quality inspections every time.

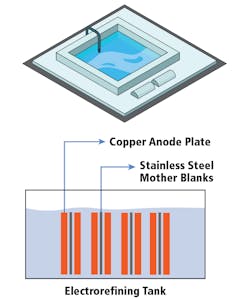

Electrolytic copper refining involves two primary components, a sheet of unrefined ore called an anode plate and a smooth, steel sheet called a mother blank. These components submerge into an electrolyte bath and an electrical charge deposits copper atoms from the anode plate onto the mother blank, forming sheets of refined copper. For the refining process to occur smoothly, the anode plate cannot have rough surfaces or edges and the mother blanks cannot feature any warping.

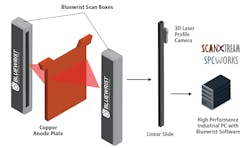

Systems integration company Bluewrist (Markham, ON, Canada; www.bluewrist.com) developed and installed 3D vision inspection systems to inspect anode plates and mother blanks at one of China’s largest copper refineries, which produces 7,000 sheets of refined copper per day for a total of 600,000 tons of refined metal per year.

The components for each Bluewrist system are contained in a scan box, a rectangular, metal housing designed for deployment in harsh environments. Each scan box includes a camera or cameras, a photoelectric eye that triggers scans to begin, and a custom PC. There are six scan boxes and four inspection stations in total on the production line: one scan box at the first inspection station, another scan box at the second inspection, two scan boxes at the third inspection station, and two scan boxes at the fourth and final inspection station.

Each scan box includes a self-calibrating Gocator 2380 3D laser profiler from LMI Technologies (Burnaby, BC, Canada; www.lmi3d.com), chosen for its 1 mm scan resolution. The camera mounts on a linear slide that moves the profiler’s laser across the surface of the object to scan and connects to the PC via wired Ethernet interface.

The PCs feature Intel (Santa Clara, CA, USA; www.intel.com) Core i7/i9 processors running Microsoft (Redmond, WA, USA ; www.microsoft.com) Windows, an NVIDIA (Santa Clara, CA, USA; www.nvidia.com) Quadro GPU, and 16 GB DDR4 RAM. Each PC runs three different proprietary Bluewrist software packages. ScanXtream software processes captured images; comXtream software manages industrial communication between robots, sensors, and PLCs and streams 3D scan data; and SPCWorks software stores the dimensions of each scanned part and gathers process control statistics.

The refining process begins with the production of the anode plate, created by pouring molten copper ore from a smelter into a metal frame (Figure 1). A Kuka (Augsburg, Germany; www.kuka.com) KR 500 industrial robot with a KR C4 robot controller submerges the plate into a quenching tank. Once cooled, the robot arm removes the anode plate from the tank and holds the plate in front of the first inspection station. This process takes place once every seven seconds.

The first inspection station conducts a 3D scan of the back of the anode plate and checks the plate for smoothness (Figure 2). A Basler (Ahrensburg, Germany; www.baslerweb.com) acA2500-14gc—a 5 MPixel CMOS area scan camera with 2.2 µm pixel and 14 fps capture rate—also installed in the scan box at the first inspection station, captures an image. The software analyzes the image to detects any cracks present in the surface of the anode plate. A L300 Linear Light from Smart Vision Lights (Norton Shores, MI, USA; www.smartvisionlights.com) provides illumination for the 2D scan.

If the back of the anode plate passes inspection, the robot lays the plate horizontally onto a conveyor belt that moves the plate to the second inspection station, where an identical pair of vision systems to the first inspection station now scan the front of the plate for smoothness and presence of cracks (Figure 3).

If any major defects are present on either the back or the front of the anode plate, the robot picks up the plate and moves it to a different conveyor belt that removes rejected plates from the refining process.

The software at inspection station two also analyzes the edges of the anode plate specifically to detect minor defects like roughness or debris. During the refining step in the electrolyte bath, the atoms drawn from the anode plate could attach to rough edges or debris and form a spike, rather than attaching to the steel sheet on the mother blank. If present, these minor defects are removed at the next step in the refining process, a station with a robot arm equipped with a circular, spinning grinder that can smooth the edges of the anode plate.

Next, a gantry crane picks up the anode plate and deposits it into the electrolyte bath, where the anode plate is sandwiched between mother blanks (Figure 4). Over the next 24 hours, the electrical current introduced to the electrolyte bath draws the copper atoms out of the anode plates and onto the mother blanks.

Once this process completes, a gantry crane removes the spent anode plates and places them onto a conveyor for delivery to another step in the refining process, to remove and refine trace amounts of metals still present in the ore.

Another gantry crane removes the mother blanks, now coated on front and back with sheets of pure copper and carries them to the third inspection station. A pair of Gocator laser profilers, one on either side of the mother blank, scan the copper sheets to detect burrs on the edges of the sheets or bumps on their surfaces (Figure 5). The results of this scan generate a quality grade for the copper. Class A designates a lack of or only a few defects and Class B designates defects within acceptable limits, for example.

The Bluewrist PC feeds the quality grade data via CAT 6e cable to a Siemens (Munich, Germany; www.siemens.com) S7-1500 PLC, which transmits the quality designation to the factory’s master control system, which then tracks each copper sheet individually. The sheets are peeled off the mother blanks by a mechanical blade, after which the sheets are placed on a conveyor belt that transports them to the final packaging machine, where they are weighed and stacked.

The gantry crane then carries the now empty mother blanks to the fourth and final inspection station, where another pair of laser profilers, one on either side of the mother blank, scan to determine the presence of warping in the sheet metal (Figure 6). If any warping is present, the gantry crane deposits the defective mother blank onto a conveyor belt that carries rejects to another part of the factory, where the defects are smoothed out.

Otherwise, the mother blanks cycle back to the electrolyte baths to use again in the refining process. They will continue to cycle through the refining procedure, first empty and then coated in refined copper, repeatedly until the mother blanks become too damaged to repair.

The refinery hosts two more production lines, identical to the line described here. Bluewrist has installed its 3D inspection application on all three lines, to accommodate the tremendous amount of copper produced annually.

About the Author

Dennis Scimeca

Dennis Scimeca is a veteran technology journalist with expertise in interactive entertainment and virtual reality. At Vision Systems Design, Dennis covered machine vision and image processing with an eye toward leading-edge technologies and practical applications for making a better world. Currently, he is the senior editor for technology at IndustryWeek, a partner publication to Vision Systems Design.