LEDs: The Swiss Army Knives of Machine Vision Illumination

If you could list the attributes of an ideal light source for machine vision illumination, the list might look something like:

High brightness: Giving you the ability to get good image amplitude with short exposure times.

Efficiency: More light power out for electrical power in to help make a greener planet and reduce operating costs.

Low-voltage operation: To help ensure safety and to be compatible with existing control circuits and wiring.

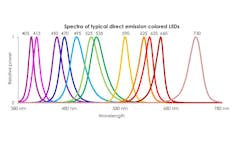

Wide color range: With wavelengths from infrared though the visible into the ultraviolet, giving a choice of monochromatic (narrow wavelength band) or white (broad wavelength band) light.

Low radiated heat: To avoid heating the objects being imaged.

Long life: Exceeding that of incandescent or fluorescent lights.

Reliability: Making catastrophic failure very unlikely.

No ultraviolet (UV) radiation: To provide a safer working environment (unless UV is desired).

Easy to control: Allow switching or pulsing with existing control circuits.

Small size: Facilitate any size illuminator from very small to very large.

Quick warm-up: Eliminate the need to wait for the light to stabilize.

Shock- and vibration-resistant: To work in mechanically challenging environments.

Environmentally friendly: Having very little toxic materials and no glass to break and cause hazards.

If that’s what you want, then light-emitting diodes (LEDs) fit your requirements.

Brief LED History

In the early days of machine vision, available LEDs were low-power and low-efficiency, only available in red, and useful only as indicators or displays—not useful for illumination. A great many machine vision applications used incandescent lamps with low efficiency, limited lifetime, and that were subject to catastrophic failures. Many other applications used fluorescent lights, which suffered from flicker and temperature sensitivity and posed an environmental hazard for disposal. Xenon strobes, arc lamps, and several other light sources were used on occasions when the need arose. The LED has replaced all of these light sources except in very special circumstances.

LED technology continued to progress. The first known use of LEDs in a commercial machine vision system was by Control Automation in the 1980s for inspecting PC boards (PCBs). That application used a large array of red LEDs that were pulsed like a strobe lamp to capture images as the PCB moved over the camera.

What happened to bring LEDs from being indicators to being a preferred source of illumination, not just in machine vision, but in almost all lighting situations? The answer lies in material science that led to developing ever more efficient materials and the methods to manufacture them. Where the original red LEDs were made from gallium arsenide phosphide (GaAsP), current materials now span the spectrum of gallium arsenide (GaAs), gallium phosphide (GaP), gallium nitride (GaN), indium gallium nitride (InGaN), aluminum gallium indium phosphide (AlGaInP), and aluminum gallium arsenide (AlGaAs). Now, LEDs are available in wavelengths from UV (350 to 400 nm), visible (400 to 700 nm), near infrared (NIR 700 to 1,000 nm), and short wave infrared (SWIR 1,000 to 1,600 nm).

It would take too much space to address each material, how it is made, and what it can be used for. Nor is this information important to know for anyone using an LED light source. What is useful is a fundamental understanding of how LEDs work.

How LEDs Work

Semiconductors are materials that are neither good conductors nor good insulators for electricity. They are found in group 4 in the periodic table of the elements such as silicon and geranium. It turns out that combining materials from groups 3, like aluminum, gallium, and indium, together with materials from group 5, like nitrogen, arsenic, and phosphorous, also results in a semiconductor. It is these materials, called three-five or III-V, that prove useful for LEDs.

In semiconductor materials, electrons can exist at certain energy levels, or bands, and not in other bands. The two important bands are the valance band and the conduction band. In between these two bands is a forbidden band where electrons cannot have this band’s energy. Electrons in the conduction band have higher energy than those in the valance band. The energy spanning the forbidden band is called the band gap.

When an electron enters an LED, it is in the conduction band. As it passes across the diode junction, it falls into the valance band. The electron’s excess energy is released. In common semiconductors (e.g., silicon), it is released as heat. In LED materials, though, it is released as a photon. The energy of the photon, and thus its wavelength, is determined by the band gap of the material.

White LEDs are produced using blue (or sometimes UV) LEDs coated with a blend of up to four phosphors that absorb some of the LED’s light and reemit it at a longer wavelength. Typical phosphors create lots of yellow light and some red light. It is difficult to get a phosphor that is efficient in converting blue to green light. So, most white LEDs have a peak in the blue region from some of the LED’s light and substantial output in the yellow and red regions, with less light in the green region.

Driving LEDs

Since the light output of an LED is proportional to the rate that electrons move from the conduction to the valance band in the device, driving the LED from a constant current source helps ensure the most stable light source. Driving an LED from a voltage source is not recommended because very small changes in voltage, or even very small changes in temperature, can result in large changes in current and light output. For simplicity, LEDs are sometimes driven through a current-limiting resistor from a voltage source. However, this does not ensure stable light output. Many LED light sources used for machine vision include a constant current circuit built into the light source or its cable.

For more demanding applications programmable drivers are available with dedicated hardware and firmware to provide either constant programmable current or a short current pulse with overdrive capability. Overdrive provides a short current pulse above the LED’s rated steady-state current. As long as the LED’s average power dissipation is not exceeded, the result is an increased light output, up to 10 times the rated light output for very short light pulses at corresponding low-duty cycles (the ratio of time on to the time from one pulse to the next).

Stability and Lifetime

For relatively low drive current, the LED responds with light output almost proportional to the drive current. As the drive current approaches the maximum value, the light output increases more slowly than the current. This is called efficiency droop. It is usually not a problem because light sources are commonly run at a constant current. In those unique instances where the LED output needs to be programmed depending on the scene, consider efficiency droop in the programming.

Like other light sources that operate near ambient temperature, the light output of an LED is temperature-sensitive. The higher the temperature, the less efficient LEDs become. The temperature effect depends on the LED material or the wavelength. Red LEDs change significantly with temperature. Blue LEDs change very little with temperature. Other wavelength LEDs have temperature sensitivities between the red and blue LEDs. White LEDs, blue LEDs covered with a phosphor, change somewhat, mostly because of the change in phosphor efficiency.

Using LEDs for illumination in areas of wide temperature range, such as outdoors where it can be snowing one season and exceptionally hot in another season, may require methods to adjust the drive (current) to the LEDs to keep their light output reasonably constant.

LEDs are known for their long life. LEDs do not ordinarily fail catastrophically when used within their current and temperature ratings but gradually lose efficiency, or light output, over their operating lives. For LED illumination, usually the L70 life is specified. This is the average operating time, in hours, at which the light output of an LED will be 70% of its initial light output. A typical L70 lifetime is 50,000 hours. If a vision system can tolerate a 30% decrease in illumination and still work within specifications, then the lifetime could range from 25 years (2,000 hours per year) down to a bit over 5.5 years if the light source is left on 24/7.

For low-duty-cycle operation, turning the LED light source on briefly when acquiring an image and leaving it off in between image acquisitions dramatically extends the LED light source’s life. Leaving LEDs off when not in use increases the lifetime in inverse proportion to the percentage of the time they are on. Even when used in overdrive if the duty cycle is low—less than 10%—the effective lifetime of LEDs is extended.

Note that the L70 lifetime for UV LEDs is significantly shorter than that for the longer wavelength LEDs but is continuing to improve.

What Color LED to Use

Clearly the application is the primary determinant of the best light wavelength. For color imaging using a color camera, white LEDs are essential. For monochrome imaging where the purpose is to provide a useful image for human viewing, usually white LEDs are also the most useful. In cases where contrast is needed between two colors, usually an LED wavelength that matches one color or the other will give the best contrast.

UV LEDs are often used for illumination to create fluorescence that can be imaged by a monochrome camera with a filter to block the UV wavelength and pass the emission wavelength. UV is absorbed by many materials such as most glass and some plastics. With an appropriate camera that is sensitive to UV and a lens designed to image UV, this wavelength can sometimes be used to image otherwise transparent objects.

IR LEDs, both NIR and SWIR, can make features visible that are not readily apparent to human vision such as the liquid level in a colored plastic bottle. Of course, using LEDs at these wavelengths requires a camera and lens that are also designed to work at the same wavelength as the LED.

When the scene has no color contrast, for example a machined part, then any color will work. However, shorter wavelengths, blue in particular, usually allow the lens to achieve its highest resolution, improving feature sharpness and measurement precision. As noted above, blue also has the best temperature stability. Also, because of the extensive work invested in blue LEDs to make white LEDs for widespread use in illumination, blue LEDs are more efficient than other wavelengths.

A downside of UV LEDs is that they are known to contribute to eye damage. However, proper care such as shielding, making sure the light doesn’t shine into operators’ eyes, and possibly turning the light on only briefly when an image is acquired, dramatically reduces the risk to workers. Light from blue LEDs is also suspected of causing eye damage. However, IEC 62471 (Photobiological Safety Of Lamps And Lamp Systems) rates the safety of blue LED light the same as for longer wavelength light.

The Future

What can you expect from LEDs in the future? The progress over time, both in LED cost and efficiency, was originally characterized by Roland Haitz around 2010. What Haitz found was that the cost per lumen of light decreases by a factor of 10 each decade, and the light generated per LED increases by a factor of 20 each decade.

While geometric progressions cannot continue indefinitely, Haitz’s law is still functioning. Look for LED efficiency to continue to increase, leading to brighter and lower power light sources. New wavelengths continue to appear as material science continues to advance. The most rapid development will be in white LEDs and the blue LEDs used to make them. There is also ongoing work to improve phosphors for white LEDs both for efficiency and for spanning the entire visible light spectrum.

If you’re working in machine vision, you are almost certainly already using light sources created using LEDs. Understanding how LEDs work and their advantages, you can develop your vision systems with greater confidence.

The author appreciates the thoughts and suggestions offered by Daryl Martin, Technical Sales and Product Specialist, Advanced Illumination, and Steve Kinney, Director of Solutions, Smart Vision Lights, during the preparation of this article.

Perry West is Founder and President of Automated Vision Systems, Inc.