LED Backlights Provide Illumination Solutions for Vision Systems

Andrew Wilson, Editor

The benefits of flicker-free light-emitting diode (LED) lighting, coupled with its low-power requirements and long lifetime, have made this technology the premiere choice for application in machine-vision systems. To properly illuminate any specific part requires an appreciation of the type of products and the speed at which they are to be inspected, and how best to highlight specific features within an image with the optimal LED illuminator.

In many cases, proper lighting can increase the contrast of image features that need to be examined, while reducing the need to employ expensive high-resolution cameras and sophisticated image-processing software. This is the main reason why system integrators should make their choice of lighting a priority when developing a machine-vision system.

As each application will be different, so too will be the choice of lighting components, the color (or frequency) of the light used, and the mode of operation (for example, whether the lighting needs to be strobed).

Luckily, a number of tutorial articles are now available online that discuss many of these different factors in great detail. Although such articles are useful, they cannot address the needs of every particular application because the properties of specific products will vary widely. To obtain the maximum contrast from any particular image may require specific lighting components such as backlights, ringlights, dome lights, or line lights that may be configured with LEDs operating in the ultraviolet (UV) to infrared (IR) range.

Solving problems

Consider what may at first be considered a trivial task: inspecting the diameters of holes within an automotive gasket. Initially, one might consider incorporating a simple white backlight to accomplish this task. Even in what may appear to be a simple task, a number of factors must be weighed including the size of the gasket and the resolution with which these measurements must be taken.

To backlight a part such as this, a number of lights of different sizes and colors can be used. Those such as the BLXXYY series of surface-mount LED backlights from Advanced illumination are available in multiple wavelengths and sizes up to 22 × 34 in.

Where these formats many not be large enough, a modular design approach can be taken that uses edge-to-edge backlights, which allows multiple lights to be combined for illuminating larger objects. A number of companies such as Advanced illumination and Microscan offer edge-to-edge backlights.

Different frequencies

Diffuse backlights are often used in systems that must measure specific parameters of parts such as automotive gaskets because the part itself will be silhouetted behind a bright background. When diffuse backlights are used, the color or wavelength of the LED lighting can affect the obtainable resolution because monochromatic light provides better feature contrast (see "Use Wavelength to Your Advantage in High-Resolution Imaging," Vision Systems Design, February 2013). Monochromatic light can reduce any axial and transverse chromatic aberration in the camera's lens and thus result in an increase in obtainable resolution.

Light with different frequencies can also be useful in applications where the level of liquids in seemingly opaque plastic containers must be determined. In these applications, the longer wavelengths of 700–1000-nm IR light may be transmitted through materials such as paper and plastic. IR backlights also have applications in food inspection (see Fig. 1). In this example, an IR backlight from Smart Vision Lights is used to inspect blueberries for Japanese beetles.

Since the IR wavelengths are transmitted through the berries, only the beetles will absorb the IR wavelength; even beetles under blueberries can be located. While backlights that employ single wavelengths can increase the potential resolution of an imaging system, the resolution can be increased further by eliminating the diffuse reflections emanating from standard backlights with collimated illumination techniques.

Collimated light

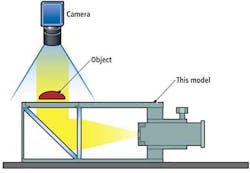

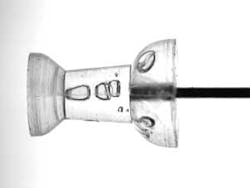

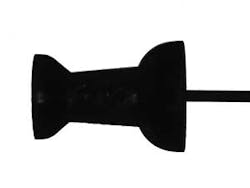

One method is to use a collimated backlight illuminator to align the diffused light from the LED array to the same optical axis as the lens. One such product is the MFU Series coaxial illuminators from CCS America. These coaxial lights radiate collimated light from behind the object to be inspected, suppressing the scattering of light (see Fig. 2).

This can be clearly seen when a pushpin is illuminated by both a backlight and coaxial illuminator (see Fig. 3). When a backlight is used to illuminate the image, light passes through the transparent object, allowing any internal defects or construction to be examined (see Fig. 3a). However, if the application requires the dimensions of the pin to be measured, collimated light is refracted to produce a sharp black silhouette (see Fig. 3b).

Coaxial illuminators offer the system developer a means to illuminate smaller parts; telecentric backlights offer an alternative, although possibly more expensive, approach. Telecentric illumination is often chosen when the dimensions of an object must be measured with very high accuracy.

Telecentric illumination

In the design of telecentric illumination systems, divergent light from a LED is collimated to eliminate any diffuse reflections that may occur when silhouetting an object. To achieve the highest possible resolution, light passing over or through the object under inspection is then captured by a camera equipped with a telecentric lens. Captured light rays from the object will then also be collimated and parallel to the optical axis.

When telecentric illumination is used as a backlight, the system designer can equip the camera system with a choice of three different types of telecentric lenses. Various companies such as Edmund Optics offer these types of lenses, known as object-side, image-side, and bi-telecentric lenses. When using an object-side telecentric lens, small distance changes of the object from the lens—within the telecentric depth of the lens—will not change the magnification of the object.

This is especially important when precise measurements of parts must be made even when the part may not be positioned precisely in the image plane. Similarly, in image-side telecentric designs, small changes in distances from the lens to the CCD or CMOS imager will not affect the accuracy of image measurement.

Combining the benefits of both these types of lenses, bi-telecentric lenses provide the highest degree of measurement accuracy. Just as with other types of backlights, telecentric illumination systems are available in a number of sizes and wavelengths. Opto Engineering offers collimated telecentric backlights in its LT CL series that feature beam diameters ranging from 16–300 mm and a choice of UV, red, green, blue, white, and IR wavelengths. To complement these products, the company also offers bi-telecentric lenses for area-array and linescan detector-based cameras.

To demonstrate the effects of telecentric illumination systems, Light Works has produced a series of images of a pair of plastic safety glasses with a human hair placed in the field of view (see Fig. 4). When imaging the glasses with a conventional lens and a diffuse backlight, the only significant feature is the human hair (see Fig. 4a). Using a telecentric lens with a diffuse backlight, scratches and dirt on the lens appear, as well as a long curved line toward the right of the hair known as a viscous thread (see Fig. 4b). By imaging the same glasses with a telecentric lens and a collimated backlight, this thread becomes more prominent (see Fig. 4c).

Numerous choices

Although backlighting is one of the most commonly used methods with which to illuminate objects, it is, of course, not the only choice of lighting available to the system integrator. Often, 2-D features such as barcodes, defects, print quality, and color measurements must be distinguished on an object's surface. Again, multiple lighting topologies exist in the form of both on-axis and off-axis illumination systems that are offered in the form of spotlights, ringlights, dome lights, and line lights in numerous configurations and wavelengths.

Like the choice of backlighting products, determining which product is best suited to inspect any particular product will be highly application specific. Positioning the correct type of lighting at the right wavelength may dramatically increase the contrast of measured features, ensuring more accurate measurements can be made effectively.

Lighting & Illumination Vendors

Advanced illumination

www.advancedillumination.com

CCS America www.ccsamerica.com

Edmund Optics www.edmundoptics.com

Light Works http://lw4u.com

Microscan www.microscan.com

Metaphase Technologieswww.metaphase-tech.com

Opto Engineering www.opto-engineering.com

ProPhotonixwww.prophotonix.com

SCHOTT North America, Inc.www.schott-moritex.com/us/

Smart Vision Lights www.smartvisionlights.com

Spectrum Illuminationwww.spectrumillumination.com

To find more lighting and illumination vendors, please visit the Illumination Systems/Lighting section of the Vision Systems Design Buyer's Guide.

Vision Systems Articles Archives