Numerous lighting methods can be used to increase the contrast of object features.

LED lighting is undergoing a period of rapid market growth in a variety of applications. Many of these have taken advantage of the high brightness and efficiencies available from colored LEDs that are now offered in a variety of configurations.

In choosing an LED illumination for a machine vision application, it is necessary to maximize the contrast between the features of the object being inspected and its background while minimizing the effect of any ambient lighting. To accomplish this, developers can choose from ring-lights, line lights, bar lights, co-axial, dome, dark field, backlights and telecentric illumination products. Numerous companies, including Moritex (Saitama, Japan;www.moritex.com) offer such products to developers of machine vision systems.

By implementing the correct type of lighting for any given application, tasks such as barcode reading, gauging and product identification can be performed more easily making the machine vision system more accurate, reliable and repeatable.

Although it may be necessary to experiment with a number of different lighting configurations before deciding on the best way to optimize contrast for any given inspection, understanding the nature of the part can simplify this process. By considering the size of the part, its geometry, color, size and texture the working distance between the part and the lighting and how quickly it needs to be inspected can simplify this process.

Luckily, a number of resources exist to aid systems developers in choosing the correct type of lighting or any particular application. In a downloadable product brochure entitled "Precision Lighting for Machine Vision," Microscan (Renton, WA, USA;www.microscan.com) shows how many different lighting products ranging from ring-lights to dome lights can best be used to optimize the contrast of features on products ranging from engine blocks, bottles, light bulbs to printed circuit boards (http://bit.ly/1NP6kRI). Other companies, such as Opto Engineering (Montova, Italy; www.opto-engineering.com) offer more specilized information on the use of telecentril lenses and terlecentric illumination.

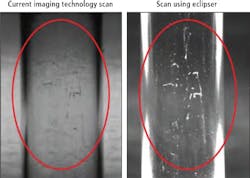

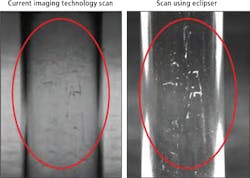

Novel lighting configurations can be used to solve a number of different types of applications. In the design of its Eclipser dark field backlight, for example, Metaphase Technologies (Bristol, PA, USA;www.metaphase-tech.com) combines LED lights and light forming optics to allow systems developers to visualize what may have been previously over-looked flaws in transparent parts such as glass or extruded or molded plastic (Figure 1).

Web applications are also benefitting from the latest developments in LED line-scan lighting. Because such applications often run at high-speed, it is critical to flood the web with the maximum amount of light as possible. Realizing this, Smart Vision Lights (Muskegon, MI, USA; http://smartvisionlights.com) has developed what it bills as the most intense and fully-focusable line light on the market. So much so that, at a recent tradeshow, attendees were required to wear a welding mask before looking at the Line High Power (LHP) Series light. Using 192 LEDs for every 300mm in length, the line light requires air or liquid cooling controlled via an external chilling system (Figure 2).

Homogeneous illumination

In other applications, it is often necessary to provide homogeneous illumination of the entire field of the part. This may necessitate using a light with a small working distance since the further that the light is placed, the more it will appear as a point source and thus the light will be less homogenous. In inspecting automobile rims with specular surfaces, for example, dome lights can be used to provide a uniform light distribution. However, these lights can be quite large and quite expensive. The MDL29.25-WHI 29.25in dome light with white LEDs from Spectrum Illumination (Montague, MI, USA; http://spectrumillumination.com), for example, costs $5,750.00.

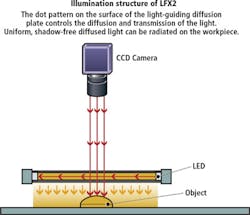

To reduce the size of these lights, companies such as CCS America (Burlington, MA, USA;www.ccsamerica.com) have introduced flat dome lights in which a dot pattern is placed on the on the surface of a light-guiding diffusion plate to control the diffusion and transmission of the light. The camera can then be placed on top of this light to image the object being illuminated (Figure 3).

In some applications, where such diffuse or specular, flat or curved surfaces require such lighting, some developers are leveraging the low-cost of edge-lit LED flat panels originally developed as replacements for fluorescent fixtures. Offered by companies such as MaxLite (West Caldwell, NJ, USA;www.maxlite.com), these can be configured in - for example a 3 x 3 array and by replacing the center panel with a camera such setups can emulate the effect of dome lighting at a reduced cost.

Using the spectrum

While the geometry of the illumination system can be used to increase the contrast of the image obtained, so too can the wavelength of light used. Since objects will absorb or reflect different objects of light in different ways using the correct wavelength of light can highlight particular features of interest. If for example, red light is used to illuminate a red object, it will appear brighter and if a green light is used, then the object will appear darker. Examples of this effect are highlighted in "A Practical Guide to Machine Vision Lighting" by Daryl Martin of Advanced illumination (Rochester, VT, USA;www.advancedillumination.com) that can be found at http://bit.ly/19gCjgg. Other companies such as Opto Engineering (Mantova, Italy; www.opto-engineering.com) offer more specilaized information on the use of telecentric lenses and telecentric backlights.

Different wavelengths can also be used to highlight different features of part since light scattering increases as the wavelength used becomes shorter. Thus using a light with a lower wavelength such as a UV light surface features will become more apparent in the reflected UV image. Using shorter wavelength light, however, may decrease the sensitivity of the imaging system since the quantum efficiency of the CCD or CMOS imager may be weaker at such wavelengths. Thus, it is important to match the sensor's sensitivity with the lighting source's wavelength to achieve optimal results.

Close to sunlight

While specialized wavelengths can be used to highlight different object features, light that closely approximates that of sunlight is useful in applications such as testing the photoelectric conversion efficiency of solar panels or faithfully revealing the colors of various objects in comparison with a natural light source. To ensure that solar panels have the highest photoelectric conversion efficiency, for example, photovoltaic manufacturers must test each of their solar modules before they can be assembled into panels.

To accomplish this in automated test applications, ProPhotonix (Salem, NH, USA;www.prophotonix.com) has developed an LED flat panel with spectral characteristics whose spectrum and intensity closely matches that of sunlight. (see "LEDs challenge Xenon flash lamps in solar panel testing", Vision Systems Design, February 2013; http://bit.ly/1kCl2OM).

In fruit or vegetable sorting, for example, it may be necessary to capture color images as they would be revealed under sunlight conditions. Here, LED illumination with a high color rendering index (CRI) is required. While the highest possible CIE rendering index is Ra100 (i.e. identical to sunlight), manufacturers such as CCS America offer 'Natural Light LEDs' that include all wavelengths of visible light from violet to red with a rendering index of Ra98 and thus characteristics very close to natural light from the sun (Figure 4). Here again, to achieve the most optimal results, it is important to match the camera's sensitivity with the lighting source.

Configuring lighting

In the past, configuring machine vision systems as a task that required knowledge not only of the correct lighting components to use, but the correct lighting controllers, software and camera timing required. Needless to say, this involved dealing with numerous vendors' hardware and software packages that needed to be seamlessly integrated. In an effort to alleviate this task, Gardasoft (Cambridge, England;www.gardasoft.com) has developed Triniti - a concept that integrates a smart Triniti controller into numerous lighting products from companies such as CCS America, Smart Vision Lights and TPL Vision (La Chevroliè;re, France; www.tpl-vision.com).

By providing integration to industry standard image processing packages such as VisionPro from Cognex (Natick, MA, USA;www.cognex.com), LabVIEW from National Instruments (Austin, TX, USA; www.ni.com) and Common Vision Blox (CVB) from Stemmer Imaging (Puchheim. Germany; www.stemmer-imaging.com), the systems developer can visualize on a single screen a timing diagram showing the trigger source, camera exposure time and lighting settings and adjust them as required.

Companies mentioned

Advanced illumination

Rochester, VT, USA

Cognex

Natick, MA, USA

CCS America

Burlington, MA, USA

Gardasoft

Cambridge, England

MaxLite

West Caldwell, NJ, USA

Metaphase Technologies

Bristol, PA, USA

Microscan

Renton, WA, USA

Moritex

Saitama, Japan

National Instruments

Austin, TX, USA;

www.ni.com

Opto Engineering

Mantova, Italy

www.opto-engineering.com

ProPhotonix

Salem, NH, USA

www.prophotonix.com

Smart Vision Lights

Muskegon, MI, USA

http://smartvisionlights.com

Spectrum Illumination

Montague, MI, USA

http://spectrumillumination.com

Stemmer Imaging

Puchheim, Germany

www.stemmer-imaging.com

TPL Vision

La Chevrolière, France

www.tpl-vision.com

About the Author

Andy Wilson

Founding Editor

Founding editor of Vision Systems Design. Industry authority and author of thousands of technical articles on image processing, machine vision, and computer science.

B.Sc., Warwick University

Tel: 603-891-9115

Fax: 603-891-9297