Choosing LED lighting and controllers for machine vision systems

Before specifying any illumination system, developers of machine vision systems must carefully consider their choice of which type of lighting must be used. If incorrectly chosen, the lighting source may result in captured images that lack contrast and cannot be processed easily by machine vision software.

Because individual parts vary greatly in their spectral properties, features, and shape, it is critical to understand how the wavelength of radiation that is used to radiate the object will be reflected, transmitted and absorbed by the object being imaged. This will depend on the wavelength of light that is used to illuminate the object, the geometric distribution of the incident light source and thus the configuration of the light source.

For example, by illuminating a part with a light of a particular color (e.g. red), contrasting colors (i.e. green) will be easier to separate because they will appear darker in the image. Should the color green be part of an embossed logo on a metal surface, then the use of low-angle red illumination may provide the highest contrast image to the imaging system.

Across the spectrum

Numerous LED lighting products are available in a number of different configurations that span the spectrum from ultraviolet (UV) to infrared (IR). Reflected UV and UV fluorescence imaging are different imaging techniques that can be used to detect features that may not be detected using longer wavelengths. In reflected UV imaging, the surface of a part is illuminated with a UV light and imaged by a UV-sensitive camera while in UV fluorescence techniques, the incident UV radiation is absorbed by the fluorescent material present in the part and is then reradiated at a longer wavelength.

Reflected UV imaging can prove especially useful in detecting the surface features of a part since wavelength of UV light is shorter than that of visible and the light will be scattered more strongly from surface features. Because of this, surface features such as scratches illuminated with UV light will become more apparent in the reflected UV image.

Figure 1 compares the use of illuminating a printed circuit board (PCB) with both visible and UV illumination. As can be seen, the visible light illuminates both the PCB features as well as foreign particles on the surface of the PCB making the foreign particles difficult to visualize. Using UV illumination, the UV light is scattered from the surface of the top layer of the board increasing the contrast of the foreign material while suppressing the PCB traces.

Should the part possess materials that are known to fluoresce under UV light, UV fluorescence may be used to increase the contrast of the material. Figure 2 shows how this technique can be used to highlight the presence of grease on a bearing. By flooding the part with UV light and measuring the reflected fluorescence, the presence of grease can be more easily visualized.

Visible wavelengths

While short wavelength illumination systems are now available in a number of different configurations, more commonly used LED products operate in the visible wavelength. Here again, it is important to choose the particular wavelength - red, green, blue or white or a combination of multiple wavelengths to increase the image contrast of the part.

Like UV light, visible light will be reflected, transmitted and absorbed differently depending on the characteristics of the object being imaged. When used in conjunction with color cameras, broad spectrum white LED lighting allows colors within an imaged to be more accurately distinguished.

In some applications, however, only specific color features within an image may need to be inspected. In such applications, choosing an LED illumination system with a light of a particular color will ensure that contrasting colors will appear darker. If an illumination system of a particular frequency is used, developers should consider whether the parts being inspected will remain consistent over the life of the vision system. Should such parts change, it may be necessary to reconfigure the lighting system or employ multi-spectral LED illumination so that the illumination wavelength can be changed dynamically as different parts are inspected.

IR illumination

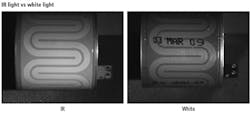

Just as UV light has a shorter wavelength than visible light and thus is more easily scattered from surface features, IR light at the opposite end of the spectrum has a longer wavelength and transmits further into specific materials such as silicon semiconductor wafers, paper and plastic products.

For this reason, IR imaging techniques are especially useful in applications such as detecting the fill level in opaque plastic containers. In applications where printed data may appear on the product to be inspected, the use of IR LED illumination can be used to effectively eliminate this data on the captured image allowing the contrast of the object under inspection to be clearly seen. In Figure 3, the use of IR light is used to remove the printed date code and highlight the heater band so it can be inspected.

Lighting configurations

Just as the choice of illumination wavelength can affect increase the contrast of an object being inspected so too can the configuration of the illumination source itself. Luckily, there are a number of different tutorials that exist to help developers of machine vision systems select the correct lighting product for their application.

In his white paper entitled "A Practical Guide to Machine Vision Lighting"(http://bit.ly/19gCjgg), for example, Daryl Martin of Advanced illumination (Rochester, VT, USA; www.advancedillumination.com) shows the effects of using different wavelengths of light and provides examples of how different products are best illuminated with different types of lighting configurations.

Like Advanced illumination, Microscan (Renton, WA, USA; www.microscan.com) also offers a number of tutorials including "Precision Lighting for Machine Vision" (http://bit.ly/1DeRAdW) and "Shedding light on Machine Vision" (http://bit.ly/1CbXF9v) that highlight the company's range of backlights, ring lights, area, linear and dome lights showing which best to use for a specific application.

While these application notes and white papers generally discuss the most common off-the-shelf; lighting topologies, lighting manufacturers realize that these products will not meet the needs of every application. For this reason, most lighting manufacturers are able to customize off-the-shelf products of develop LED lighting with novel configurations. One such light, the rather oddly-titled "Curved Linear light" from Smart Vision Lights (Muskegon, MI, USA; www.smartvisionlights.com), for example, is especially useful in illuminating round object such as bottles where the light can be wrapped around curved surfaces (Figure 4). By connecting four such lights together, the complete surface of round objects can then be uniformly illuminated.

To ease the task of such custom configurations, Spectrum Illumination (Montague, MI, USA; www.spectrumillumination.com) has developed what the company calls a Tripod Modular Light System - a Lego-like lighting system that allows individual triangular-shaped illumination blocks to be either used separately as a spotlight or together to create single, double or multiple row linear lights, large area lights, ring lights or rectangular ring lights. Because of the lightings modular design, developers can create lighting in the shape of an "L", "U" or "S", as required (Figure 5).

Lighting controllers

While the choice of the type of LED illuminator and wavelength is important, so is the choice of the lighting controller. These constant current sources are supplied either by the manufacturer of the light sources, by third-party lighting controller manufacturers or embedded into the light sources themselves (see "Lighting controllers for machine vision applications", Vision Systems Design, Vol. 19. No. 2; http://bit.ly/18i9wH0).

Whether to choose an illumination source with an integrated or external LED controller is, like the choice of the lighting used, application dependent. In some applications, it may be necessary to continuously illuminate a product being inspected, in others, the LED illuminator may need to be strobed to capture images at high-speed or multiple lights may be required to illuminate an object with intensity levels. Thus, while integrated LED illumination systems and controllers may provide a cost and footprint saving in some cases, more complex multi-light strobed systems may be more cost-effectively configured with a multi-channel external current controller.

Unlike the many tutorials that exist which describe the different types of lighting configurations that can be deployed, only a few different sources exist to aid the developer in choosing the correct type of lighting controller. Perhaps one of the most informative of these is "LED Controllers Technical Overview and Selection," from Gardasoft (Cambridge; UK; www.gardasoft.com) that can be found on the company's website at: http://bit.ly/1CcNNxV.

Indeed, one of the most novel developments over the past year has been the development of the company's Triniti concept (see "Intelligent lighting aims to simplify machine vision design" Vision Systems Design, Vol. 19. No. 9; http://bit.ly/1x1vlGB). By integrating a Triniti Chip in its LED lights, CCS America (Burlington, MA, USA www.ccsamerica.com) and Smart Vision Lights allow an external Gardasoft controller to poll the light for its product type and model number and electrical characteristics such as the current required by the light, its duty cycle and the current required to produce a given brightness (Figure 6).

Once such parameters are known, the lighting controller can be configured to produce the correct type of illumination. Better still, the company's Triniti API allows developers to view and configure the parameters of both the lighting controller, the intelligent lighting products and synchronize these with external cameras.

Company information

Advanced Illumination

Rochester, VT, USA

www.advancedillumination.com

CCS America

Burlington, MA, USA

www.ccsamerica.com

Gardasoft

Cambridge, UK

www.gardasoft.com

Microscan

Renton, WA, USA

www.microscan.com

Smart Vision Lights

Muskegon, MI, USA

www.smartvisionlights.com

Spectrum Illumination

Montague, MI, USA

www.spectrumillumination.com

About the Author

Andy Wilson

Founding Editor

Founding editor of Vision Systems Design. Industry authority and author of thousands of technical articles on image processing, machine vision, and computer science.

B.Sc., Warwick University

Tel: 603-891-9115

Fax: 603-891-9297