Custom cameras classify plastic pellets precisely

In the recycling of plastic products, incoming plastic is ground into flakes, washed and dried, and, converted into pellets. These pellets are manufactured by melting the plastic and then extruding and cutting the plastic material into small, uniform pieces. Once manufactured, these plastic pellets must be sorted before they are sold to manufacturers to be made into new products, such as bottles and trash bags. Measuring approximately 1/4 in. in diameter, the plastic pellets are often delivered by the ton on railroad cars to plastics manufacturers. After unloading, thousands of pellets per minute must be sorted using high-speed automated systems.

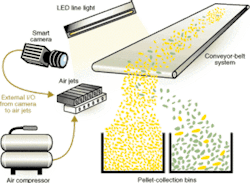

To accomplish this inspection, one or more linescan cameras and PC-based frame grabbers build an image of every pellet as it travels along the conveyor belt. After inspection, machine-vision algorithms determine which parts are acceptable and which must be ejected. PC-based systems trigger air-jets at specific points to blast out the unwanted pellets.

"Implementing complex algorithms in a PC is an everyday task for many machine-vision companies," says Kerry Van Iseghem, founder of Imaging Solutions Group of New York (ISG; Fairport, NY, USA; www.isgchips.com). "Software from major vendors is easy to use and powerful. But some customers require high performance and low cost where custom image-processing algorithms must be embedded in the camera."

System operation

ISG has recently developed such a system using its LightWise LW-SLIS-2048 Smart Camera, a 2048 × 1-pixel linescan camera that incorporates an 8051 MCU and a programmable FPGA. After plastic pellets are loaded onto a conveyor belt system from Leeds Conveyor Manufacturing (Guildford, CT, USA; www.leedsconveyor.com), they are illuminated by an LL3148 LED line light from Advanced Illumination (Rochester, VT, USA; www.advancedillumination.com). After the pellets are detected by the linescan camera, the captured images are processed on-board by this camera.

"Typically, " says Van Iseghem, "image-processing algorithms determine the gray-scale level of objects within an image, and then threshold algorithms are used to set the limits of what is sorted. As the black-and-white plastic pellets are being scanned, there may be a threshold limit of 50; this is set where 0 is pure white and 255 is pure black [in an 8-bit system]."

When pellets are scanned and determined to have a threshold greater than 50, the camera triggers a number of air-jets from Parker Hannifin (Cleveland, OH, USA; www.parker.com) that are powered by a C403L air compressor from Gardner Denver (Quincy, IL, USA; www.gardnerdenver.com). The air-jets push each rejected plastic pellet into a defective-pellet bin.

"With such designs," explains Van Iseghem, "our customers pay a nonrecurring engineering charge for the algorithm's customization and implementation in hardware inside the camera. When it is completed, the need for the PC is eliminated and the algorithm's performance is optimized. This lowers the system cost and enables OEM customers to offer sorting machines at lower prices to their customers. Since the machines are optimized, they can sort more material faster, and the end customers throughput is increased."