Piezoelectric stages make positioning stages precise

Andrew Wilson, Editor, [email protected]

Precise and accurate angular positioning with fast dynamic response is vital to many defense-related applications that use rotary positioning devices in angular scanning systems. These positioning devices are currently found in infrared (IR) search-and-track, light-detection and ranging, and airborne laser weapon systems.

Companies such as Raytheon (Waltham, MA, USA; www.raytheon.com), Lockheed Martin (Bethesda, MD, USA; www.lockheedmartin.com), Harris (Melbourne, FL, USA; www.harris.com), and Goodrich (Charlotte, NC, USA; www.goodrich.com) currently supply products that use angular scanning systems. However, while the electronics and signal-processing aspects in these systems have improved dramatically, the electromechanical and scanning subsystems have remained essentially the same as they were in the late 1960s.

Developed primarily for IR systems, these subsystems had modest demands on resolution, angular accuracy, and dynamic response. However, the growing use of high-resolution cameras and narrow-beam laser-tracking and scanning devices are now making increasingly stringent demands on angular accuracy and dynamic response in the specifications of the scanning systems. These demands must apply within the exacting environmental requirements-reference frame inertial motion, platform vibration, ranges of temperature, and humidity-of defense-related projects. “The need to couple rotary stages to inertial guidance systems to ensure platform stability in this scenario has called for innovation on the part of designers,” says Valentin Zhelyaskov, vice president of Discovery Technology International (DTI; Sarasota, FL, USA; www.dti-nanotech.com).

Today, ball-joint gimbal systems are used for dynamic steering as an alternative to mechanical gimbals in many sensor-tracking devices. However, the Kevlar lines that transfer motion from servomotors to the mirror stages can slip or stretch, compromising system accuracy, as well as limiting dynamic response. In addition, the nonlinear characteristics of the conventional servo or stepper motors in these systems limit their accuracy, repeatability, and tracking performance.

“To overcome these limitations,” Zhelyaskov says, “a new type of piezoelectric rotary motor can be used. The motor allows direct-drive angular positioning with superior high resolution and accuracy that can be measured directly by optical encoders. The motor yields performance that cannot be matched by conventional (electromagnetic) motor-based tracking systems. Indeed, because the piezoelectric-based rotary motor does not have any supplementary transmission system, entailing gears or Kevlar lines, its accuracy closely approaches the intrinsic positioning resolution of the motor itself.”

Furthermore, it benefits from improved dynamic performance and wider tracking bandwidth (for example, 3 kHz), without the drawbacks associated with hysteresis, drift, and the need for high-voltage power supplies. Moreover, because the angular position of the rotor is held fixed by the self-decelerating torque of the motor, the same force locks the drive, which results in low angular drift over time. A high initial torque also enables a fast start-stop response.

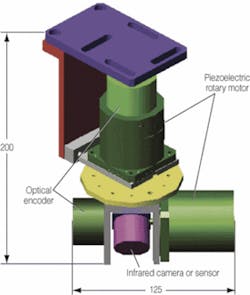

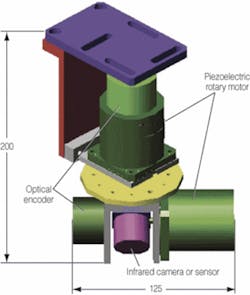

DTI is developing a tracking system based on this technology that provides both microradian resolution and microradian accuracy combined with low hysteresis and almost zero backlash. The design uses a new type of piezoelectric rotary motor that does not require a high-voltage power source and uses near-zero power to hold the system at a fixed position. Direct coupling between the piezoelectric rotary motor and rotary stage eliminates the usual problems caused by mechanical tolerances in supplementary transmission systems, thus yielding practically negligible backlash and hysteresis.

“The direct-drive piezoelectric rotary stage currently under development by DTI has a resolution of 0.5 arc sec, with an absolute positioning accuracy of 3 arc sec in closed-loop mode using an optical encoder. Its angular positioning accuracy is at least an order of magnitude better than those found in currently available systems,” Zhelyaskov says.

To program and control the rotary stage from Windows or third-party applications such as LabView from National Instruments (Austin, TX, USA; www.ni.com), the system uses a proprietary digital-signal-processor-based control platform, operating from a 12-Vdc source. The system will be targeted for deployment in areas where weight, size, and reliability are critical.