3D cameras ensure the accurate development of custom shoe insoles

Foot impression foams help orthopedists to develop shoe insoles that provide customers with comfort and additional support for their feet throughout the day. In order to create accurate measurements of the foams, foot fitting company paromed developed a portable 3D measurement system.

"Up to now, we were implementing the foot impression foam system in a non-mobile scanner," said Georg Näger, Development Manager at paromed, "but to ensure an individual service, it is necessary to realize the precise detection even mobile."

The portable system is based on an Ensenso 10 3D camera from IDS Imaging Development Systems. Ensenso N10 stereo cameras feature two 752 x 480 pixel global shutter CMOS image sensors, and a USB interface. The N10 cameras feature an infrared pattern projector that projects a random pattern of dots onto the object to be captured, allowing structures that are not visible or only faintly visible on the surface to be enhanced or highlighted. This is necessary because stereo matching requires the identification of interest points in a given image.

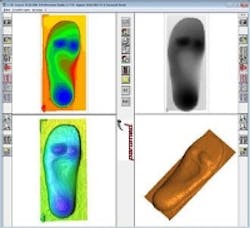

Once interest points are identified, the object is then captured by the two image sensors and 3D coordinates are reconstructed for each pixel using triangulation. Even if parts with a relatively monotone surface are placed in the bin, a 3D image of the surface can be generated. Customers who require an individual footprint for the production of insoles stand barefoot onto the foot impression foam, which deforms and adapts to the physiological characteristics of the feet. The N10 3D camera then captures a 3D image of the footprint in the foam box.

From there, 3D point clouds are converted, filtered, and displayed in an internal file format. A CAD system for individual modeling of shoe insoles processes the additional image data, which is used for either shaping shoe insoles from blanks or in a 3D printer.

Paromed also uses software and drivers from IDS for image capture and analysis. "We use the uEye API and Ensenso nxLib to integrate the camera," said Näger. "It works very well with our own code."

He added, “We have developed a mobile solution that is cost-effective, portable and easy to use."

View more information on IDS 3D cameras.

Share your vision-related news by contacting James Carroll, Senior Web Editor, Vision Systems Design

To receive news like this in your inbox, click here

Join our LinkedIn group | Like us on Facebook | Follow us on Twitter | Check us out on Google +

About the Author

James Carroll

Former VSD Editor James Carroll joined the team 2013. Carroll covered machine vision and imaging from numerous angles, including application stories, industry news, market updates, and new products. In addition to writing and editing articles, Carroll managed the Innovators Awards program and webcasts.