Testing IR Cameras

Randy Bockrath and Kevin Norwood

From night-vision helmets, scopes, and security cameras to machine-vision systems, infrared (IR) cameras are addressing the needs of both mission-critical and industrial applications. While companies that produce IR cameras need to test the image quality of IR sensors and lenses, R&D prototypes, preproduction products, and their final camera products, organizations that use IR cameras may need to benchmark competing devices, perform acceptance testing on random samples, and verify proper camera functioning after setup and maintenance. To monitor IR system performance, standardized test equipment and procedures are required.

Testing the image quality of an IR camera involves imaging a test chart with known image properties (e.g., sharp edges, precisely known colors, parallel lines) and analyzing the captured image to determine sharpness, aberration, accuracy, noise, distortion, and other image quality factors. To perform this analysis, adequate contrast must be present in the captured image.

Imaging challenges

Unlike cameras developed to image the visible spectrum, IR cameras present a challenge for software-based image quality analysis because it is difficult to predict what materials will produce contrast at various IR wavelengths. Since IR cameras capture both reflected and emitted light, this can result in a captured image having little contrast, thereby preventing software-based analysis of image qualities.

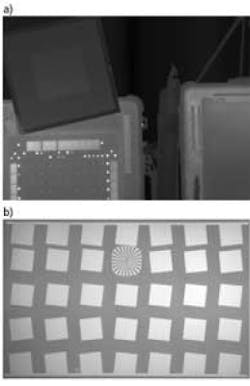

To test IR cameras, a number of companies have developed specialized test chart substrates and coatings that deliver contrast in required IR wavelengths. Many such test charts are based around the 1951 USAF test chart pattern or similar patterns. However, such charts are poorly suited to computer-based analysis because they contain only vertical and horizontal lines (see Fig. 1).

Also, because of the high cost of materials used to produce IR charts, these charts are typically small, often not exceeding 100 in.2 This size limits applicability for testing many IR cameras, since the test chart may not fill the complete field of view (FOV) of the camera. Indeed, in many cases, the materials used to make these small charts cannot scale to large size (e.g., 2400 in.2) at any cost.

Most existing charts are designed exclusively for laboratory environments. Consequently, they do not allow image evaluation to be performed in the field where many IR systems are routinely operated. To overcome these limitations, Imatest has partnered with the United States military’s White Sands Missile Range (WSMR) and Vandenberg Air Force Base (VAFB) to deliver a test chart that could measure, analyze, and document IR system performance in both lab and field operating environments.

Finding a substrate and coating for the chart that delivered acceptable contrast in IR wavelengths, could be produced in large sizes, was durable in outdoor environments, and was substantially less expensive than available IR charts proved to be challenging. Ultimately, an aluminum substrate was used and an IR coating of IR pigments with special enamels was applied to the substrate. The resulting test chart supports a range of wavelengths, from visible light through the mid-wave IR (MWIR) region of the electromagnetic spectrum (see Fig. 2).

Comparing images

Using the chart, comparisons of test images were made using a visible light camera, a short-wave IR (SWIR) camera, and an MWIR camera (see Fig. 3). Darker pigments in the central square show up against the lighter background in both visible and SWIR bands. However, contrast depends more on emissivity than color in MWIR imagery and materials were carefully selected to exploit this property at longer wavelengths.

Besides being visibly darker, the center square coating exhibits higher emissivity at MWIR wavelengths than the surrounding light-colored background. This yields good contrast for MWIR imagers (see Fig. 3c). Notably, contrast is visible in all three images, underscoring the multispectral nature of the test pattern design.

At MWIR wavelengths, the temperature of the test chart impacts the level of contrast in a captured image. Because MWIR imagers primarily detect both reflected and display thermal radiation, increasing the temperature can enhance contrast between high-emissivity coatings and low-emissivity coatings on the test chart.

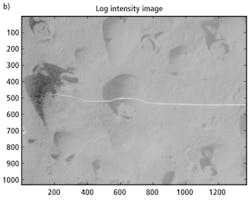

A change of approximately 10–20°C transforms the contrast from an unusable level (see Fig. 4a) to a level suited for computer-based image analysis (see Fig. 4b). Necessary heating can be achieved through solar heating (when the test chart is used outdoors during the day), or through use of heating pads (at night or in an indoor test laboratory).

After an image of the IR SFRplus test target is captured, it can be analyzed using Imatest’s IR Edition software package. This implements image-quality test algorithms now commonplace in the testing of visible light camera systems. The software recognizes the IR SFRplus test chart pattern and automatically selects relevant regions of interest for analysis. Measurements of image-quality factors such as sharpness, distortion, and noise (as a signal-to-noise ratio) are then computed by the software.

When a prototype chart was sent to White Sands for field evaluation with a modern MWIR imaging system, post-test analysis of the captured imagery revealed a slight defocus error. The error was investigated and attributed to a loose back-focus mechanism on the IR lens, which had been previously undetected. Ironically, a simple test constructed to evaluate the chart’s performance revealed significant information about the camera’s performance.

Sharpness, distortion, and noise

Sharpness, arguably the most important image-quality factor, is most closely related to the amount of detail an image can render. Relative contrast at a given spatial frequency (output contrast/input contrast) is called the modulation transfer function (MTF) or spatial frequency response (SFR).

Two of the best indicators of perceived image sharpness are the spatial frequencies where MTF is 50% of its low frequency value (MTF50) or 50% of its peak value (MTF50P). These numbers are often the same, but they may differ for strongly sharpened systems. Other measures of sharpness such as MTF20, the spatial frequencies where MTF is 20% of its low frequency value, which is closer to the traditional vanishing resolution (roughly MTF10) are also important.

Because of the many slanted edges in the SFRplus test chart pattern, sharpness can be measured across the imaging plane. Here, sharpness is greatest in the image center and falls off toward the edges of the image, a common result in many camera systems. More detailed information about the sharpness of each vertical edge selected for analysis is also provided by the software and is reported as the mean edge and MTF response.

Distortion is an aberration that causes straight lines to curve and has two forms: barrel and pin-cushion. Distortion tends to be most serious in extreme wide angle, telephoto, and zoom lenses and can be visible on tangential lines near the boundaries of the image, but not on radial lines. In a well-centered lens, distortion is symmetrical about the center of the image. Lens distortion is reported by the software using the metric Standard Mobile Imaging Architecture (SMIA) (SMIA; www.smia-forum.org) TV distortion measured in this image at -5.48% (see Fig. 5).

FIGURE 5. Lens distortion is reported by Imatest’s software using the metric Standard Mobile Imaging Architecture (SMIA) TV distortion measured in this image at -5.48%.

Advances in IR test charts and analysis software will transform IR camera testing by leveraging modern visible-light image-quality testing practices with more sophisticated IR test charts. Such advances will benefit a range of companies that design, manufacture, and integrate cameras.

Randy Bockrath is CEO of Imatest (www.imatest.com), and Kevin Norwood is senior systems engineer, New Mexico Technology Group (NewTec), White Sands Missile Range, NM, USA (www.newtecllc.com).