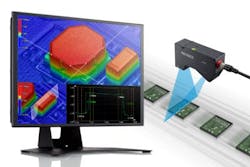

3D vision system for inline inspection to be shown by Keyence at Automate

Keyence’s new 3D vision system is a plug-and-play, inline-inspection solution that features point-and-click tools for measurement of 3D objects. The vision system—which will be on display at Automate—is equipped with the newly-developed HSE3–CMOS image sensor and utilizes a blue short wavelength 405 nm laser, a GP-64 processor, and a 2D Ernostar lens. The 3D vision system is available in multiple models, including the highest accuracy model, the LJ-V7020, which has a measurement range of ± 2.3 mm (height), 6.5 mm width (near side width), 7 mm (reference distance width), and 7.5 mm (far side width). When integrated with Keyence’s single-click, programmable encoder, the 3D vision system can acquire accurate, scaled images for inline inspection applications.

Automate 2017 booth number: 2240

To Learn More:

Contact: Keyence Corporation

Headquarters: Elmwood Park, NJ, USA

Product: 3D vision systems

Key Features: Blue laser technology, HSE3–CMOS image sensor, 3D geometry toolset, 64,000 profiles/s speed, GP-64 processor.

What Keyence says:

View more information on the 3D vision systems.

View More Products| Locate a vendor or system integrator | Receive e-mail updates

Share new products that you think are particularly interesting or helpful by contacting James Carroll, Senior Web Editor, Vision Systems Design.

Join our LinkedIn group | Like us on Facebook | Follow us on Twitter

Learn more: search the Vision Systems Design Buyer's Guide for companies, new products, press releases, and videos

About the Author

James Carroll

Former VSD Editor James Carroll joined the team 2013. Carroll covered machine vision and imaging from numerous angles, including application stories, industry news, market updates, and new products. In addition to writing and editing articles, Carroll managed the Innovators Awards program and webcasts.