PCI boards turn on Pentium power

PC IMAGING BOARDS

By Andrew Wilson,Editor

Board-level manufacturers are harnessing the ever-increasing power of the PC to perform more image-processing functions.

As the processing power of general-purpose CPUs continues to increase, the number of image-processing boards that feature on-board RISC-, DSP-, or CPU-based processors has decreased dramatically. Rather than manufacture intelligent vision processors with on-board processing capability, most board-level manufacturers have developed more-sophisticated frame grabbers capable of interfacing to a range of high-performance cameras. And rather than rely on on-board processors, these companies are harnessing the increasing power of the PC processor to perform more image-processing functions.

FIGURE 1. Full-length PCI-board, the Alacron FastImage1300 PCI-based frame grabber, can be populated with up to four TriMedia processors, each with 8 to 16 Mbytes of 572-Mbyte/s SDRAM. Capable of providing more than 2.6 to 3.6 GFLOPs, each processor connects to dedicated memory via the board's TriMedia memory interface.

This approach has its merits. Newer processors such as the Intel Corp. (Santa Clara, CA) Willamette have been clocked at 1.5 GHz. The processor's pipelined design provides a set of 144 new instructions, which is compatible with the streaming single-instruction multiple-data extensions of the Pentium III processor, to accelerate video and encryption technologies. In addition, it features a 400-MHz system bus that runs three times faster than the 133-MHz system bus used with today's Pentium III processor.

With these developments, designers of vision and image-processing equipment are taking advantage of low-cost, high-performance processors, off-the-shelf PC-based development tools, and image-processing software. Using such host-based processing power, many board vendors argue that the necessity for on-board processing power has become redundant.

For example, Imaging Technology (Bedford, MA), recently purchased by Coreco Inc. (St. Laurent, Que., Canada), now takes the approach that users require either embedded machine-vision engines or FPGA-based frame grabbers. While the company's NetSight product is offered in the form of an embeddable MMX-based vision system running under Windows CE OS, the company's PC-LineScan frame grabber features an on-board FPGA design for run-length encoding and flat-field correction. Plug-in expansion modules can also be custom designed by users and added to the board.

ON-BOARD PROCESSING

Vendors of PCI-based image processors that incorporate CPUs, DSPs, and RISC processors, however, still argue the merits of on-board processing. "Notably, an excellent DSP processor, the Intel Pentium III, is limited by the PC's surrounding logic," says Joseph Sgro, chief executive officer of Alacron Inc. (Nashua, NH). "Although the AGP [accelerated graphics port] bus improves this situation, its design will ultimately limit its scalability. Therefore, the most practical solution for a demanding application remains a coprocessor board that is more scalable, has higher throughput, and ultimately is cheaper than the native solution," he adds.

Alacron, a vendor of the ADSP-2106x, Philips TriMedia, and Motorola Altivec-based image-processing boards, has added Channel Link low-voltage differential signaling technology to its FastImage1300 and FastImage PCI-based coprocessor boards. The FastImage 1300 is based on the Philips' TriMedia processor and uses a very-long-instruction-word architecture capable of delivering 667 to 720 MFLOPs and 833 to 900 MIPs per processor.

The FastImage board, a full-length PCI-board, can be populated with as many as four TriMedia processors, each with 8 to 16 Mbytes of 572-Mbyte/s SDRAM and is capable of providing more than 2.6 to 3.6 GFLOPs. Each processor connects to dedicated memory via the board's TriMedia memory interface (see Fig. 1). Using the DS90CR285 (transmitter) and DS90CR286 (receiver) chipset from National Semiconductor (Santa Clara, CA), the board's 230-Mbyte/s data-acquisition rate is used to interface to RGB cameras. At the Vision Show West (San Jose, CA; Oct. 2000) Alacron will introduce its FastVision board. Based on the Altivec processor, the board uses a CISC/RISC architecture capable of 3600-peak MFLOPs and 450 MIPS/processor.

POWER PC IMAGING

Originally based on the TMSC80 processor from Texas Instruments (Dallas, TX), the PCI-based Genesis processing board from Matrox Imaging (Dorval, Que., Canada) operates in conjunction with a main PCI board that performs image digitization and display. Linked over a custom video interface ASIC, image data can be transferred between the boards at rates to 132 Mbytes/s.

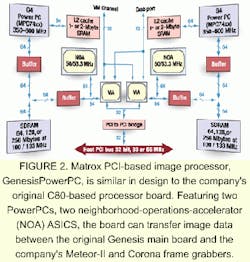

At the Vision Show West in October, Matrox also will announce its next-generation vision-processor based on the Motorola Inc. (Phoenix, AZ) PowerPC. Like its previous C80-based board, this new processor board will feature two processors and two of the company's neighborhood operations accelerator ASICS (see Fig. 2). Like the previous Genesis processor, the board can transfer image data between the original Genesis main board and the Matrox Meteor-II and Corona frame grabbers.

REAL-TIME IMAGING

But it's not just the added speed that board vendors are touting as a reason for using their products. They point to the scalability that allows users to select the right system configuration and price-performance point for their application. What's more, they note that users can maintain their application-software development investment, the flexibility in interfacing with a variety of cameras, and the availability of vision software toolkits and application-development environments.

As PCs have become faster and more prevalent, many vendors have gravitated to the low-cost vision-system configuration of a frame grabber and software. This approach is appropriate for users who already have a PC in their system as a machine controller or user interface front end that can devote substantial host CPU processing bandwidth to vision tasks. However, for situations in which the PC is dedicated to other tasks or where multiple vision systems with many cameras are used, the alternative configuration of a vision-processor board that plugs into a PCI backplane is a viable alternative.

FIGURE 2. Matrox PCI-based image processor, GenesisPowerPC, is similar in design to the company's original C80-based processor board. Featuring two PowerPCs, two neighborhood-operations-accelerator (NOA) ASICS, the board can transfer image data between the original Genesis main board and the company's Meteor-II and Corona frame grabbers.

Real-time operating systems, such as VxWorks from Wind River Systems (Alameda, CA), are often used on such embedded vision-processing engines because of their deterministic interrupt processing time and accurate control of task priorities. All time-critical, on-board image-acquisition, vision-processing, input/output, communication, and control tasks are optimally handled by a deterministic, real-time, multitasking operating system, whereas graphical user interface and application development tasks are best handled by the host PC.

John Agapakis, general manager of the machine-vision business unit at RVSI Acuity CiMatrix (Canton, MA), says, "Until recently, users had to choose either the embedded vision-processing engine or the host CPU processing model. They often had to deal with complex cross-development environments for developing and deploying applications with embedded processors. Furthermore, they could not easily leverage their application-development investment as they moved from one processing configuration to the other."

At this year's Semicon West show, RVSI Acuity CiMatrix announced two additions to its Visionscape 1000 and 2000 series of boards and a new release of its Visionscape AppFactory application-development environment. AppFactory allows users to deploy applications they develop on a host PC onto either a 1000-series accelerated frame grabber or a 2000-series embedded vision-processing engine.

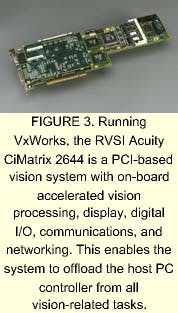

FIGURE 3. Running VxWorks, the RVSI Acuity CiMatrix 2644 is a PCI-based vision system with on-board accelerated vision processing, display, digital I/O, communications, and networking. This enables the system to offload the host PC controller from all vision-related tasks.

Running VxWorks, the Visionscape 2644 board is a complete PCI-based vision system with on-board accelerated vision processing, display, digital I/O, communication, and networking functions (see Fig. 3). These enable the board to off-load the host PC controller from all vision-related tasks. As many as six vision boards can be inserted in a single PCI backplane. The 2644 board interfaces to a variety of machine-vision cameras with support for high resolution, progressive or partial scanning, electronic shuttering, and simultaneous asynchronous capture from four independent input channels.

The RSVI Acuity 1640 board, which offers the same camera interface and digital I/O options as the 2644 board, is configured as an accelerated frame grabber that couples its on-board vision ASIC to the host PC's CPU, which runs under Windows NT. "This lower-cost vision board can be used when the host PC controller can devote processing bandwidth to vision tasks," says Agapakis.

To support the entire Visionscape family of boards, the company offers a toolkit of vision and automatic identification tools and an application-development environment that allows users to create and deploy applications through a Windows NT GUI. Systems integrators and OEMs who want to embed the vision-system functionality inside their machine-controller graphical user interface can use Visionscape's ActiveX software component architecture.

PERSONAL COMPUTER POWER

Rather than use multimedia or RISC processors, Coreco Inc., Cognex Corp. (Natick, MA), and Datacube (Danvers, MA) are using the power of general-purpose processors on-board their latest products. There, however, the similarity between the three company product lines ends.

As a Pentium II-based embedded vision processor designed to accelerate machine-vision and medical-imaging applications, Coreco's Mamba board off-loads the intensive image-processing tasks from the host computer and executes these tasks on its embedded processor. Using the Windows NT operating system with the company's FASTSeries of MMX-optimized imaging libraries, the Mamba board allows specific imaging applications to be loaded from the host, the on-board Disk-On-Chip (DOC), or a network controller using Microsoft's Visual Studio software.

FIGURE 4. As a stand-alone image computer, the Coreco Mamba board features 512 Mbytes of on-board memory, 48 Mbytes of on-board DOC, an on-board VGA controller, a 100-BaseT network controller, 2 IDE ports, one floppy-drive port, two serial ports, and one parallel port. To perform image processing, developers can use the Coreco Viper series of PCI frame grabbers to transfer images to the processor at 200 Mbytes/s via the Coreco auxiliary bus.

The Mamba board, a stand-alone image computer, provides 512 Mbytes of on-board memory, 48 Mbytes of on-board DOC, an on-board VGA controller, a 100-BaseT network controller, two IDE ports, one floppy-drive port, two serial ports, and one parallel port. Twelve optoisolated I/O lines allow the board to interface to the external environment. To perform image processing, developers can use Coreco's Viper series of PCI frame grabbers to transfer images at 200 Mbytes/s via the Coreco auxiliary bus to resolve PCI bus-contention issues that could result in image data loss (see Fig. 4).

Cognex also uses a programmable processor, the Advanced Micro Devices 400-MHz K6-2, to power its MVS-82400 PCI-based machine-vision-system board. Rather than use additional boards to perform image acquisition, however, this PCI board accepts the addition of daughter cards, called Cognex video modules, to digitize data from RS-170/CCIR video sources and digital linescan and progressive-scan cameras. Running under Windows NT, the board is offered with the company's Cognex vision library, which provides low-level Visual C++ access to Cognex vision tools. To speed image-processing functions, the board also features a Cognex custom ASIC that operates transparently during board programming.

SYSTOLIC ARRAYS

At the Vision Show West, Datacube is slated to announce its next-generation image processor—the MaxVideo 2000, which features several innovative technological developments. "In previous MaxVideo designs," explains Philip Hill, Datacube vice president of engineering, "developers have configured a series of processing elements to form a pipelined image processor." Because each element could only perform a specific function, developers first needed to understand the nature of their problem, and then configure the pipeline elements to perform data acquisition, processing, and storage.

"Although such pipelining allowed developers to implement powerful image processors," says Hill, "it also required understanding the physical arrangement of the elements on the board, and how to configure each type of processing element. Sometimes there could be too few of one type of element while other types of elements remained unused."

Datacube's MaxVideo 2000 product line might appear, at first glance, to be a radical departure from pipelined architecture. But, in fact, it is built using exactly the same philosophy: stream the data through the processors. From a hardware perspective, MaxVideo 2000 consists of a PCI-based image-acquisition motherboard and an image-processing board. The host motherboard features six gigabit Ethernet inputs; a 64-bit, 66-MHz PCI bridge chip; a memory controller; and glue logic (see Fig. 5).

Bolted to the motherboard are two mezzanine cards. One is a Pentium MMX-enabled processor (233 to 450 MHz) with 64 Mbytes of memory. The other is a memory-based mezzanine module that carries up to 2 Gbytes of SDRAM with a 1.0-Gbyte/s bandwidth; it is controlled using the motherboard's custom-built memory controller.

"One of the major problems associated with image processing," says Hill, "is balancing I/O, memory, and processing capabilities." Accordingly, Datacube's motherboard directs six Gigabit Ethernet channels to acquire and direct data at rates to 400 Mbytes/s to the contiguous 2-Gbyte on-board memory. To acquire data from high-speed line cameras, Datacube offers a series of sensor cards to interface to LVDS- and linescan-based cameras, such as the CTF3 from Dalsa Inc. (Waterloo, Ont., Canada). "Acquiring sensor data, whether it is analog or digital, close to the image sensor is very important," comments Hill, "especially in applications where the host PC may be located at long distances from the image sensor."

Once images are on-board the MaxVideo 2000, they can be accessed by the embedded or host Pentium using direct memory access over the PCI bus. In addition, image data can be transferred over the 800-Mbyte/s board-to-board interface to the MaxVideo 2000 processing board. Functioning as a separate full-length processor, this board also contains a Pentium processor and 2 Gbyte of high-bandwidth memory. It also features a systolic array of image-processing cells that can be configured to perform image-processing functions; the company claims that this processing executes at speeds an order of magnitude faster than today's DSPs.

FIGURE 5. To digitize analog data from high-speed line cameras, the MaxVideo 2000 product line from Datacube features a series of sensor cards to interface to LVDS and linescan-based cameras. Once digital images are transferred at Gigabit Ethernet rates to the MaxVideo 2000 PCI motherboard, they can be transferred over the board's 800-Mbyte/s interface to the MaxVideo 2000 processing board. This board features a systolic array of image-processing cells that can be configured on-the-fly to perform image-processing functions.

The MaxVideo 2000 processing board is populated with four systolic- array ASICs, each of which contains a seven-by-seven lattice of imaging cells. Because each cell houses a crosspoint switch, multipliers, arithmetic logic units, and memory, it can be dynamically reconfigured on-the-fly to perform a variety of different image-processing functions. In this approach, a total of 196 cells are used to form a reconfigurable pipelined image processor. According to Hill, this design results in a processing power of 78 billion multiply/accumulates per board per second. This processing takes place up to five times faster than boards based purely on DSPs or CPUs, such as the TigerSharc DSP from Analog Devices (Norwood, MA) and the Altivec G4 or G5 CPU processor from Motorola (Austin, TX).

Rather than competing with the latest off-the-shelf CPUs from Intel and others, image-processing vendors realize that they must add value in the form of image acquisition, processing power, and memory bandwidth. To do so, many vendors have implemented their own ASICs or programmable processors to perform image processing, but they still harness the power of the Pentium and other processors to perform system control and housekeeping. In the future, image-processing-board vendors will need to push the performance of their products even further. Next-generated products are expected to emerge that are targeted specifically at image processing and will increase performance by orders of magnitude.

Company Information

Due to space limitations, this Product Focus article does not include all of the manufacturers of the described product. For information on other suppliers of PCI-based imaging boards, see the 2000 Vision Systems Design Buyers Guide (Vision Systems Design, Feb. 2000, p. 69, System Boards).

Analog Devices Inc.

Norwood, MA 02062

Web: www.analogdevices.com

Alacron Inc.

Nashua, NH 03060

Web: www.alacron.com

Cognex Corp.

Natick, MA 01760

Web: www.cognex.com

Coreco Inc.

St. Laurent, QC, Canada H4T 1V8

Web: www.coreco.com

Dalsa Inc.

Waterloo, ON, Canada N2V 2E9

Web: www.dalsa.com

Datacube Inc.

Danvers, MA 01923

Web: www.datacube.com

Imaging Technology

Bedford, MA 01730

Web: www.imaging.com

Intel Corp,

Santa Clara, CA 95052

Web: www.intel.com

LynuxWorks

San Jose, CA 95124

Web: www.lynuxworks.com

Matrox Electronic Systems

Dorval, QC, Canada H9P 2T4

Web: www.matrox.com/imaging/

MIPS Technologies

Mountain View, CA 94043

Web: www.mips.com

Motorola Inc.

Phoenix, AZ 85072

Web: www.motorola.com

National Semiconductor

Santa Clara, CA 95052

Web: www.national.com

RVSI Acuity CiMatrix

Canton, MA 02021

Web: www.rvsi.com

Texas Instruments

Dallas, TX 75265

Web: www.ti.com

Wind River Systems

Alameda, CA 94501

Web: www.wrs.com