3-D system profiles highway surfaces

A custom laser line and CMOS-based imaging system measure road-surface smoothness.

By Cor Maas

Road-surface analysis is conducted by contractors and state and federal departments of transportation as part of safety and quality checks of new roads and as part of inventory assessments of existing roadways. The smoothness of a road surface impacts many aspects of travel by highway. For example, too much surface variance from the norm can result in an uneven ride, increased vehicle wear, a shortened road-surface lifetime, and safety concerns. Producing the correct road surface can affect as much as 5% of a multimillion-dollar paving contract.

The basic road-surface analysis procedure measures the smoothness of roads in the vehicle wheel path as a test vehicle drives the road at highway speed. The problem is complicated by the need to make surface measurements under uncontrolled lighting conditions and on surfaces that range from black asphalt to white concrete in varying environmental conditions.

In the past, engineers developed time-of-flight ultrasonic transmitters to measure the road’s smoothness or profile, but at travel speeds these systems only could collect 1 data point per foot. The next-generation system was a laser triangulation sensor, which bounced a single laser point off the road and collected the same triangulation data. Using pulsed-laser illumination with a fast read-out sensor enabled the second-generation system to collect data every millimeter, but only at one point.

“The single-point system worked great on a lot of surfaces, but when the road had longitudinal structures, such as grooves for greater traction, the laser point would wander in and out of the groove as the car drifted across the lane, yielding unrepeatable data,” explains Daniel Howe, US market manager for LMI Transportation Division. Asphalt roads have built-in texture because of the aggregate used, but for concrete roads a texture has to be created. In many cases the texture is longitudinal in nature, which is why this problem needed to be solved, specifically for the American Concrete Pavement Association (ACPA; see Fig. 1).

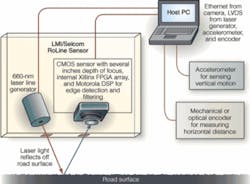

Transportation engineers at the University of Michigan Transportation Research Institute (UMTRI) tackled the problem by using the Selcom RoLine sensor developed by LMI Technologies. The RoLine system generates up to 100 data points across the wheel path with submillimeter precision. The measurement data from the RoLine are collected by OEM profiler machine builders and combined with two external analog interfaces, an accelerometer for vehicle dynamics, and an encoder for vehicle travel distance to achieve a true road profile. By moving from laser point to laser-line illumination, the road profiler delivers 10-mm forward spatial resolution at highway speeds and provides 100 data points across a 100-mm width-or approximately the width of a standard automobile tire.

Lasing the Road

UMTRI recently tested the RoLine sensor on roadway conditions as part of the ACPA Profiler Repeatability Tests. The system was positioned in the wheel path in a test vehicle and driven at below highway speeds (see Fig. 2).

The sensor housing includes a custom StockerYale line generator at 660 nm with line-generating optics. LMI uses both CMOS and CCD imagers in its laser-triangulation systems. However, this system uses a CMOS imager optimized for dynamic range, among other proprietary parameters, and custom optics to accommodate changes in focal depths as the car moves up and down while it travels over the road. An on-board Xilinx FPGA reads out the sensor data at frame rates up to 3 kHz, while providing initial image correction and processing, such as gain, sensor timing, and other camera-control functions. FPGAs provide for additional processing speed for multiple operations (see Fig. 3).

The Xilinx FPGA outputs a digital signal to a dedicated Motorola DSP, which runs LMI’s proprietary image-processing algorithms. Laser-triangulation systems generate height information along the z axis by projecting a flat laser line onto a surface, collecting an image of the line, and measuring the defection of the line from the horizontal norm. When properly calibrated and mounted at the correct stand-off location, the distance the line varies from the norm directly translates to the surface height at that point.

For the purposes of the test, the RoLine sensor data were run through a bridge-height algorithm that filters the data points to generate an “intelligent” mean height average of the tire contact point. LMI’s Howe says, “While we have a basic bridging algorithm embedded in the sensor, most of our OEMs are choosing to receive the full profile data and using their knowledge and experience, are creating their own bridging algorithms. UMTRI’s Steve Karamihas is looking to test and determine the best approach, and, once that is done, we can incorporate this algorithm into the sensor to offload computing tasks from the OEMs host computer to the sensor itself.”

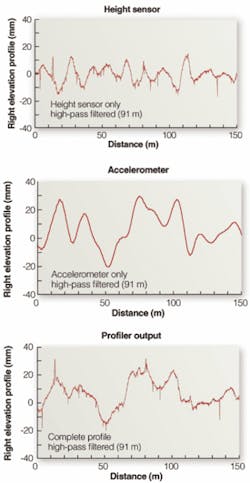

Vehicle-mounted systems that move require two additional pieces of data to generate a repeatable road-surface map: vertical and horizontal movement data on the vehicle itself. In this case, an accelerometer is attached to the top of the system enclosure to measure the up and down movements of the vehicle, and a distance-measuring instrument (DMI) is used to get the vehicle travel distance. OEM profiler manufacturers combine these signals and through filtering techniques achieve a true elevation profile of the pavement surface relative to distance (see Fig. 4). Profiler machine builders process the data streams on a host computer, based on various accelerometers and DMIs-some optical, some mechanical-and many different approaches to filtering and software.

Speedy Networks

The existing RoLine system is mainly concerned with determining road height at any given point and how the frequency of movement will impact the natural frequency of a car’s vertical movement. Future improvements to the road-profiler system might include using multiple sensors and an improved network system to keep all devices in synch, including the Global Positioning System.

Since this profiler system was tested last year, Selcom has developed a proprietary bus called FireSync for sensor input. When multiple units in a system are used, synchronizing those units becomes a difficult issue. When driving on the road, all inputs should be sampled in a synchronous way. FireSync utilizes a dedicated network control box with proprietary Gigabit Ethernet cabling that adds additional control wires for the laser and guarantees data synchronization from multiple systems. The time between data points between sensors is reduced to less than 1 μs using FireSync.

“The road profiler with LMI/Selcom RoLine lasers demonstrated vastly improved repeatability over the prevailing fleet of road profilers,” notes UMTRI’s Karamihas. “The testing was performed at the request of the ACPA and included four surfaces of diverse macrotexture that, together, are very challenging to most profilers. This application is difficult, because it requires measurement to tight tolerances on very smooth pavements with a high level of macrotexture.”

“The availability of line lasers for road profilers is a recent development,” says Karamihas. “It will provide us with the opportunity to write new standards for accuracy that ensure relevance of the measurements to end-user satisfaction-that is, vehicle dynamic response to road roughness. Since the RoLine is very flexible in the way that it interprets each reading, I expect it to be compatible with any relevant standard that is developed in the near future.”

COR MAAS is president of Selcom Sensors That See, a division of LMI Technologies, Heerlen, The Netherlands; www.sensorsthatsee.com.

null