How Metal Recycling Facilities Use IoT and Thermal Imaging to Improve Early-Warning Fire Detection

David Bursell, VP of Business Development, MoviTHERM

Metal Recycling facilities are finding ways to mitigate and prevent fire damage by implementing the Internet of Things (IoT) with early fire detection technologies like infrared (IR) cameras.

Recycling facilities receive flammable materials like lubricants, paints, grease, oil, propane, gas tanks, and batteries mingled with recyclables. As recycled materials are cut, crushed, compacted, or shredded as part of the recycling process, any traces of flammable substances can ignite when pressure is applied or sparks from friction are present.

In recent years, scrap metal recycling facilities have experienced an increase in fire activity. The cause for the rise is attributed to increased numbers of lithium-ion batteries in the waste stream. The growth of lithium-ion batteries in consumer goods and an emphasis on recycling have more battery waste in recycling centers. Lithium-ion batteries can experience thermal runaway and catch fire if broken or crushed, thereby magnifying an already hazardous condition when added to the scrap metal recycling process.

Early Fire Detection Devices

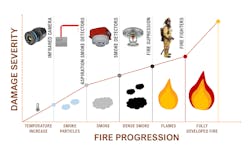

There are various fire detection sensors available today that alert scrap recycling facility managers of fire formation with varying detection timing during the progression of a fire. Figure 1 shows the relative detectability of fire detection devices at different stages of fire development with corresponding damage levels.

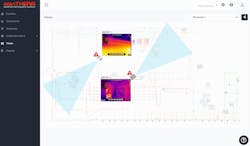

IR cameras operate on the heat transfer principle of radiation. The IR camera has a focal plane array of detector elements that sense IR light from object surfaces. The radiation captured by the IR camera detector is digitized, converted to data, and displayed as a viewable image. Calibrated IR cameras can report temperature measurements from specific spots, lines, and areas on live or recorded images. IR cameras are available in different wavebands, pixel resolutions, lens configurations, and communication protocols to meet various installation requirements.

IR camera systems are the first to alert before a fire develops. They “see” a material warming early in the fire development process before forming smoke particles or flames. These warming materials appear as hot spots in a thermal image and are quantified with regions of interest (ROI) that report temperature values. Applying multiple ROIs to an image and setting temperature thresholds per ROI allows monitoring and alarming multiple locations within the camera’s field of view. When threshold conditions are met, alarms trigger alerts to the appropriate personnel.

IoT and Early Fire Detection (EFD)

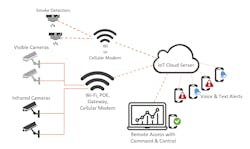

The Internet of things (IoT) refers to interconnected sensors, instruments, and other devices networked into software applications that use predictive analytics and artificial intelligence (AI). These connected networks create systems that can monitor, collect, exchange, analyze, and deliver valuable insights into a system or process. IoT uses cloud computing to simplify integration and enhance process control.

Fire safety is an area that realizes the benefits of IoT when combined with thermal imaging and other fire detection sensors. By connecting sensors that alert at different stages of fire development and varying conditions for fire formation, facilities can more readily detect and prevent potential fires. With IoT, safety alerts are sent to hundreds of people quickly and effectively. Communication options include voice calls, texts, and emails to targeted recipients to establish quick and effective awareness. Another advantage of IoT EFD is scalability. Facility managers can connect multiple facilities into a central monitoring and alarming dashboard. Understanding the situation at all facilities improves the oversight and management of multiple systems from a single control point.

IoT EFD systems can improve emergency planning by using algorithms and analytics to help quickly prepare better emergency and evacuation plans. For example, analytics can consider factors such as the number of people in the facility, facility maps, location of the fire, and the rate at which the fire is spreading to develop better evacuation plans. Analytics-based evacuation plans can prevent congestion by guiding workers to different locations for optimum evacuation routing.

IoT EFD systems are less expensive to install and maintain than traditional detection systems. Because the EFD software resides in the cloud, there is no need for a dedicated facility computer server. Additionally, any potential for operating system software conflicts is eliminated because access to the cloud-based application only requires an Internet connection. Users access the EFD system anywhere, anytime with any Internet-connected device. And, anyone with the appropriate credentials can remotely modify control and alarm settings to optimize performance.

Another key advantage of a cloud-based EFD system is sharing dashboards and map views with others. For example, sharing a live map view with first responders en route allows for scene assessment before arriving on site, saving time and optimizing safety. These map views identify the alarm sensor location, monitored area, alarm conditions, facility entry, and exit points.

IoT EFD in Metal Recycling Facilities

IoT EFD systems in metal recycling facilities integrate multiple detection technologies to track temperatures and detect smoke particles at critical locations. The most common detection sensors for metal recycling EFD include:

- IR cameras for quantitative and qualitative monitoring of hot spots.

- Visible cameras identifying smoke or flame.

- Aspirating smoke detectors for detecting smoke particles.

Correct sensor selection and placement within a metal recycling facility are critical to ensure optimum detection performance. For example, IR cameras require a direct line of sight to the area of interest to provide detection. Critical areas obscured from the camera’s field of view could be monitored by smoke detectors, thereby augmenting the camera’s detection. For outdoor or high-airflow installations, IR sensors are best for detection as dilution effects may limit smoke detectors’ performance.

Another critical consideration for metal recycling EFD is early warning notification to individuals responsible for material handling. Before EFD, material handlers would unknowingly spread hot materials, increasing the size of the fire hazard. With EFD and early alert notifications, informed heavy machine operators can avoid problem spots and prevent spreading potential fire hazards.

Recycling facilities benefit when working with experienced fire detection integrators who thoroughly examine installation sites before designing the detection system and ensure the system includes best-fit sensors in the best locations.

It is important to note that IoT EFD systems do not replace existing detection and response protocols for metal recycling facilities. Instead, the system functions as an early warning system, detecting areas in the facility where ignition may occur. New detection methods for heat, smoke, and fire are continually developing. Many new detection devices include wireless capabilities that make integrating IoT EFD a straightforward exercise. Beyond alarms and notifications, IoT EFD systems can provide automation controls like initiating and directing an extinguishing system. Because IoT EFD systems leverage cloud computing, they require less hardware with a reduced installation burden. Available communication technology can be added to existing detectors, making retrofitting existing systems for IoT easy. By warning earlier on the pathway to ignition, metal recycling center operators avert costly and potentially life-threatening fires before they can start and spread. Because IoT EFD systems are easily configurable, they operate in settings beyond metal recycling that benefit from early fire detection, including coal, biomass, industrial laundry, wood processing, trash bunkers, and more.