SWIR imaging is a type of non-visible imaging. SWIR stands for shortwave infrared, which is a band of light just beyond human vision. It ranges from about 900 nm to 2300 nm. SWIR light transmits through silicon, so sensors for SWIR imaging typically use indium gallium arsenide (InGaAs) based detectors. “The SWIR wavelengths will get passed through silicon, so you can’t make a SWIR sensor out of silicon,” says Glen Ahearn, Sales & Application Support Manager, Teledyne DALSA (Waterloo, ON, Canada; www.teledynedalsa.com). “One of the fundamental properties of a sensor is that it is struck by incoming photons that are absorbed at some layer in the silicon wafer, converted to electrons, and that charge is then stored in each pixel well on that sensor. To absorb the light and turn it into a charge and store that charge, you can’t have the light passing directly through it. If the SWIR light is going to pass right through the silicon, you can’t make your SWIR sensor out of silicon. InGaAs is material that will absorb the SWIR light, much like the silicon absorbs visible light, and it will convert it into a charge that is stored and then read out at the appropriate time.”

Besides that difference and that it involves different wavelengths of light, SWIR imaging is similar to visible light imaging in that you have the same basic components: the light, the camera, lensing, and whatever peripheral equipment there may be.

Good for Some but Not All

Ahearn explains that all machine vision applications have one thing in common: detecting or measuring anything requires contrast. “You might have objects that reflect well and give you good contrast in visible light—and since most machine vision applications are visible light today, there’s no real reason to stray from that,” he says. “What SWIR can do for you, depending on the objects you’re looking at, is give you better contrast than you can get from visible imaging.”

Materials behave differently in different light wavelengths. Since SWIR imaging is similar to visible light imaging, just with different wavelengths, the idea is to find the contrast. Ahearn states that if users can’t get the contrast they need in visible light alone, SWIR light may be the answer. “I say ‘may be’ because I don’t think that everyone knows all the different ways all materials on the planet react to SWIR light,” he adds.

Emerging Applications for SWIR

According to Ahearn, recycling is a very suitable application for SWIR. Not all plastics can be recycled. So, recycling centers need a way to identify what plastics are coming through their facilities and split them up. One way plastics are identified is with the triangle shape containing a resin code number found on most plastics. The numbers go from one to seven, and each represents a different type of plastic. Plastics that can be recycled must be differentiated so they are sent down the appropriate line. Just glancing at the variety of plastics that comes through with our own eyes, it would be difficult at best to find the triangle symbol and read the number on it. A machine vision application could try to locate that triangle and read the number, but Ahearn says there’s no way it could do that efficiently because the triangle is very small and could be positioned anywhere. “It could be occluded by something else,” he says. “So, a solution that can look at the entire plastic surface is much more robust.”

SWIR light is a solution. If a recycling center images all the plastics using several different bands of SWIR light, for example 1200, 1300, and 1500 nm, and coalesces the information, Ahearn says users arrive at a 3D dataset. “By the way,” he adds, “when you do that, it’s now called multispectral or hyperspectral imaging.” The 2D image includes horizontal and vertical dimensions, with the third dimension being the wavelength. “You build up your data cube and using that, we can now distinguish between these different types of plastics,” says Ahearn. “Because each one has a signature. Plastic 1 might be high in one wavelength and low in another wavelength. Plastic 2 might be exactly the opposite, and Plastic 3 might be different still. Using these multiple bands and looking at those signatures tells us what kind of plastic it is. That allows the plastics recycler to sort and differentiate those plastics and put them into different bins so they can go off and be recycled at that point.” The vision system sorts the plastics and communicates with a mechanical system that pops the different pieces of plastic down different chutes to the proper container.

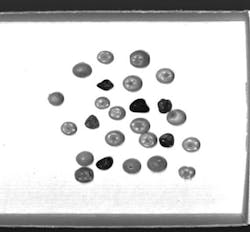

Another application is food inspection. Water absorbs SWIR light at about 1450 nm. If, for example, a camera looks at a piece of fruit high in water content, rather than getting light photons bounced back at it, it gets almost nothing because the water in the fruit has absorbed the light. With SWIR imaging, it appears very dark relative to other items in the same field of view that do not contain a high amount of water. Ahearn explains that there are a number of ways this can be used in food or agriculture applications.

One is to differentiate food from what some in the agricultural industries call trash, i.e. items that end up on a conveyor belt during a harvest like sticks, stones, leaves, or branches. The water content in the fruit is going to be different from that in a stone—which gets back to contrast. “You now have something that’s almost white vs. something that’s almost black,” says Ahearn. “It’s very easy to detect the contrast and sort based on the water content.”

Another emerging application is chemical analysis, particularly for pharmaceuticals. Solid pills, for example, are formed by pill-making machines. When a pharmaceutical company forms the pill, that pill will have the active ingredient and other inert ingredients required as filler. While the best-case scenario is that the active chemical would be evenly distributed throughout an entire batch, the reality is that there could be problems when mixing all the ingredients. Or, the mix hasn’t completely dissipated through a vat of pharmaceuticals properly. There could also be pills formed with no active ingredient. To the naked eye, the active and filler ingredients often look the same. However, the chemicals may react differently under SWIR light.

As usual, it depends on what is being inspected, but generally there’s a very good chance, according to Ahearn, that the active ingredient will look different than the filler under SWIR light. “Again, it gets back to contrast,” he says. “It would almost be like finding streaks of blue in yellow paint. It’s going to be pretty easy to do if you’ve got a big vat of yellow paint and you’ve got some blue streaks in it. But if you’ve got white filler and a white chemical, you can’t tell how well they’re mixed together. SWIR is a technology that will help determine if the chemical vat is uniformly mixed so when it creates pills on the back end, the pills all have the same amounts of active ingredient and filler in them.”

This is also important when considering the distribution within the pill of each chemical. Some pills can be split in half, with the idea being the person taking the pill is getting ½ the dose. But, if it’s not distributed evenly, the customer might get the active ingredient all at once or nothing at all.

Finally, SWIR light’s ability to go through silicon proves very useful for solar panel inspection. Since solar panels are made largely out of semiconductor material (silicon), SWIR light can be used to transmit through the semiconductor material to see defects that might be covered by the silicon. “You can see cracks or defects by being able to see right through that silicon as if it’s a glass window,” says Ahearn.

SWIR Application Lab

SWIR is an emerging technology to use for imaging, and Ahearn says, “We still don’t know what we don’t know. All applications depend on what you’re doing, what material you’re working with, and what you are trying to do. There are very few absolutes in vision inspection where you can say, ‘This will work for this.’ It’s all very specific to the application.” This has led Teledyne DALSA to create what it calls the SWIR Application Lab (Billerica, MA, USA; https://bit.ly/3KZr4dZ). The lab includes cameras, lights, and mechanical transport to move objects under the camera to help potential customers see if SWIR light is suitable for their application. “Since, as an industry, we are all still learning about how SWIR can help us, we’ve offered this service to our potential customers,” says Ahearn. “We will take their samples, get an explanation of what it is they’re trying to do, and use the equipment we have here to scan their samples, produce images, and write a description of what we found.”

The report includes the images, what wavelengths were used to create them, and the results Teledyne DALSA determined for each wavelength to help potential customers determine if SWIR light is going to help with the application. “It’s one of those things where you just don’t know until you’ve tried it,” adds Ahearn. “I’m a huge fan of empirical testing when it comes to anything. I like to put something down on a transport or desk, create an image of it, and see what it looks like under conditions that it would be exposed to in a real machine vision application. That’s the only way you can really start to get a handle on these types of things.” Ahearn says that since the lab’s creation, it has performed a number of scans with very interesting results. “It’s showing that SWIR has the promise to solve a number of problems that can’t be solved in visible light.”

To learn more about Teledyne DALSA’s SWIR Application lab visit: https://www.teledynedalsa.com/en/products/imaging/cameras/linea-swir/.

About the Author

Chris Mc Loone

Editor in Chief

Former Editor in Chief Chris Mc Loone joined the Vision Systems Design team as editor in chief in 2021. Chris has been in B2B media for over 25 years. During his tenure at VSD, he covered machine vision and imaging from numerous angles, including application stories, technology trends, industry news, market updates, and new products.