Introduction to Reverse Engineering

Reverse optical engineering, also known as reverse engineering in optics, is the process of taking an existing optical component or system, analyzing it, and replicating it to create a similar or improved product. This technique is useful when the original design is not available or when improvements need to be made to an existing product.

One of the main benefits of reverse optical engineering is the ability to create a custom optic system that meets specific requirements. Optic systems are used in a variety of applications, such as medical devices, telecommunications, and military equipment. By reverse engineering an existing system, manufacturers can create custom optics that are tailored to their specific needs.

Another benefit of reverse optical engineering is the ability to replicate state-of-the-art optics designs. Optical components and systems can be complex, and creating a design from scratch can be time-consuming and costly. By reverse engineering an existing design, manufacturers can replicate the design more easily and cost-effectively, saving time and money in the process.

Reverse optical engineering also allows manufacturers to improve on existing optical systems. For example, they can analyze the design of an existing system and identify areas where improvements can be made, such as reducing chromatic aberration or improving the focal point. By making these improvements, manufacturers can create a more effective and efficient product.

In terms of specific capabilities, reverse optical engineering can replicate a wide range of optical components and systems, including plano concave lenses, cylindrical lenses, and other types of lenses. Manufacturers can also choose from a variety of lens materials, depending on the specific requirements of their application.

Reverse optical engineering relies on a unique set of manufacturing capabilities. One of the key capabilities is the ability to analyze and replicate the behavior of light rays as they pass through an optical system. This requires advanced knowledge of optics design and the ability to use specialized software and equipment.

Manufacturing capabilities also include the ability to create complex optical components using a variety of techniques, such as diamond turning and injection molding. These techniques allow manufacturers to create precise components with high levels of accuracy and repeatability.

In conclusion, reverse optical engineering is a valuable technique for creating custom optics and improving existing optical systems. It allows manufacturers to replicate state-of-the-art designs and make improvements to existing systems, resulting in more effective and efficient products. With a unique set of manufacturing capabilities, reverse optical engineering can replicate a wide range of optical components and systems, providing manufacturers with a cost-effective way to create custom optics that meet their specific requirements.

What Avantier does –

At Avantier, we specialize in providing comprehensive reverse engineering solutions for a wide range of industries. With our expertise in reverse engineering techniques and state-of-the-art technology, we offer a reliable and efficient process to recreate and analyze existing objects, components, or systems. Whether you need to replicate a discontinued part, enhance an existing design, or gain a deeper understanding of a product’s functionality, we have the knowledge and capabilities to assist you.

What Avantier does in reversing engineering –

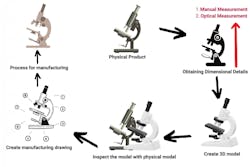

- Test samples: Once received the sample, our engineers will capture precise and detailed measurements of the object or component. This non-destructive process ensures that the original item remains unharmed while providing us with accurate digital data.

- Model Generation: The collected tested data is then processed and converted into a high-quality computer-aided design (CAD) model or optical drawing. Our skilled engineers utilize industry-leading software to create a drawing representation of the object, capturing its geometry, dimensions, and intricate details.

- Analysis and Optimization: Once the drawing is generated, we conduct a thorough analysis to understand the component/assembly design. This analysis enables us to identify areas for improvement, optimize the design, and suggest enhancements based on your specific requirements.

- Prototyping and Manufacturing: With the finalized model, we can proceed to the prototyping and manufacturing phase. Whether you need a functional prototype for testing or a fully manufactured component, we utilize advanced manufacturing technologies to deliver high-quality results.

- Quality Assurance: Throughout the reverse engineering process, we maintain strict quality control measures to ensure the accuracy and reliability of our work. We employ rigorous inspection methods and validation procedures to verify that the replicated component or system meets your specifications.

Please contact us if you’d like to schedule a free consultation or request for quote on your next project.