June 2016 snapshots: Infrared cameras in life sciences, aerial vision system inspects power lines, vision processing in IR

IR cameras image water absorption in crops

Plant phenotyping company LemnaTec (Aachen, Germany;www.lemnatec.com) has developed a system called the Scanlyzer 3D, which features visible and IR cameras to provide researchers with data on plant growth, root development, water absorption and drying and photosynthesis.

Scanalyzer3D is an automated system that provides quantitative, nondestructive measurements on cultivated crops in greenhouses. In the system, plants pass through a series of optical measuring spaces in which they are imaged using various wavelengths. This is repeated at various stages of the plant's growth cycle, so that researchers can collect data over time. The system consists of five separate measuring stations, each of which performs distinct functions:

At the first measurement station, temperature differences among individual plants or within a single plant (e.g. from one leaf to another), are measured with a Pearleye P-030 LWIR camera from Allied Vision (Stadtroda, Germany;www.alliedvision.com). This IR camera features a 640 x 480 amorphous silicon uncooled micro-bolometer FPA with a 25μm pixel size that can achieve frame rates of 24fps.

At the second station, a Prosilica GT6600 camera images plants from different angles, documenting their size, growth, and development over time. This GigE camera features a 29MPixel ON Semiconductor (Phoenix, AZ, USA;www.onsemi.com) KAI-29050 CCD image sensor with a 5.5μm pixel size and can achieve a frame rate of 4fps.

At the third station, a Goldeye infrared camera from Allied Vision captures images of roots in the shortwave, near-IR range, documenting moisture and absorption, along with the root system's efficiency.

This camera is also used at station four, where the section of the plant above the soil is analyzed in the same manner. Captured images provide information on the water content of the stem and leaves, and the plants' recovery following drought.

At the final station, fluorescence technology is used to highlight particular substances, such as chlorophyll. Plants' pigments are stimulated using blue light with a wavelength below 500nm, with measurement taking place above this wavelength.

Of particular interest for bio-scientists is the use of IR cameras in the 900-1700nm range. Using IR cameras, a plant's moisture content, or the water distribution within the plant, can be highlighted. Because water strongly absorbs infrared light in a wavelength range from 1450 to 1500 nm, it appears black and opaque in an IR image, so that aqueous areas within a plant appear correspondingly darker.

With this technology, scientists can follow water absorption from the roots into the leaves, as well as evaporation and desiccation.

Data captured in the Scanalyzer3D is analyzed and processed by LemnaTec's software, LemnaGrid. Additionally, tools such as LemnaMiner and LemnaShare ease data export and exchange for further processing by a research team.

LemnaTec's clients for the Scanalyzer3D include BASF, Bayer Crop Science, DuPont, and international research institutions such as ACPFG (Australia), ICAR (India), and the French national agricultural research institute, INRA.

Aerial vision system uses LIDAR to inspect power lines

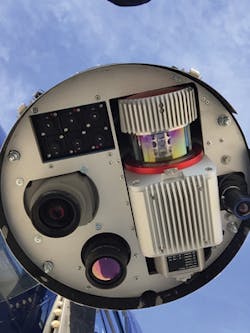

Italian aerial data acquisition company Birdview (Domodossola, Italy;www.birdview.org) has developed a metric survey system that uses a variety of sensors, including LIDAR, IR and CCD sensors in a gimbal mount that can be easily transferred from one aerial vehicle to another.

Birdview's missions are typically flown in helicopters and are meant to assist utility companies to control and maintain their power and pipeline network and carry out annual quality control checks. Over time, Birdview's clients requested higher accuracy survey data for their quality control of new and existing power lines and pipelines. Because of this, Birdview added a Riegl (Horn, Austria;www.riegl.com) VUX 1 LIDAR and a Phase One (Frederiksberg, Denmark; http://industrial.phaseone.com) iXA-R 160 CCD camera, which is available in North America through 1st Vision (Andover, MA, USA; www.1stvision.com).

The iXA-R 160 camera features a 60Mpixel CCD image sensor with a 6μm pixel size that captures full resolution frames at 1.3 fps. The camera is configured with a Rodenstock (Munich, Germany;www.rodenstock.com) 40mm lens and has a USB 3.0 interface, 72 dB dynamic range and facilitates bi-directional communication with the flight management system (FMS).

The use of the LIDAR in combination with the iXA-R 160 enables the company to obtain higher resolution images. These are necessary to capture minute details of the wires' conductors, poles, and the changes in temperature of the wire over the year. This is important to analyze, as it enables utility companies to determine when a cable needs to be replaced.

Helicopters carrying this metric survey system typically operate from an altitude of 150-200m above the top of power lines, where the LIDAR has a beam footprint of approximately 75-100mm. Standard Birdview projects entail capturing approximately 2,000 to 3,000 images a day.

Phase One's iXA-R 160 camera was chosen because of its small size and weight and can be controlled from the Riegl RiACQUIRE software, which also controls the LIDAR, eliminating the need for other software to run in the aircraft.

"The camera can capture images in bad weather conditions which is important as long power lines need to be examined in a short amount of time, especially in places like the Alps, where the weather can change quickly," says Alessio Mugnaioli, Managing Director of Birdview.

The pod, which also contains an IMU and global navigation satellite system, can be attached to different aircraft, and returned to Italy for processing. In post-processing, Birdview uses the Riegl RiPROCESS software for the LIDAR data and the software package from TerraSolid for orthophoto production. Standard deliverables include point clouds, shape files and orthophotos.

Vision processing comes to infrared imaging

Movidius (San Mateo, CA, USA;www.movidius.com) is collaborating with FLIR Systems (Wilsonville, OR, USA; www.flir.com) to bring computer vision to the company's Boson thermal imaging camera core. FLIR will integrate a Myriad 2 Vision Processing Unit (VPU) into the core. Customized collaboratively with FLIR, the Myriad 2's 12 programmable vision cores allowed FLIR to implement image processing, noise filtering and blending algorithms and OEM image processing and analytic algorithms.

FLIR's Boson is now available in VOx microbolometer IR arrays that have a 12μm pixel pitch, multiple field of view options, and NETD of 40mK. The cameras will feature embedded video analytics, software-customizable functionality for video processing and power dissipation and built-in support for physical and protocol-level interface standards such as Ethernet, USB and wireless video. Additionally, the cameras feature inputs and processing for auxiliary sensors.

The new Boson infrared camera core targets such applications as handheld thermal imaging systems, security and surveillance, UAVs, robots, navigation, obstacle avoidance and automotive driver's vision enhancement.