SOLAR/PHOTOVOLTAICS MANUFACTURING: LEDs challenge xenon flash lamps in solar panel testing

To ensure that solar panels have the highest photoelectric conversion efficiency,photovoltaic manufacturers must test each of their solar modules before they can be assembled into panels. Each panel must be subjected to a stable optical light source whose spectrum and intensity closely matches that of sunlight. Because the efficiency of the photovoltaic device is the ratio of the power delivered relative to the optical power incident on the panel, measuring the delivered power from the device under known lighting conditions provides a measure of photovoltaic efficiency.

To accomplish this in automated test applications, artificial light sources with a low spatial nonuniformity and high temperature stability must be used. To properly match the spectrum of these light sources with sunlight, photovoltaic vendors and the American Society for Testing and Materials (ASTM;www.astm.org) have developed a standard terrestrial solar spectral irradiance distribution known as ASTM G-173 AM 1.5 that defines a spectral irradiance that occurs if the Sun is at a 48.2° angle to the plane of the solar panel.

At this angle, the Sun will deliver an approximate 1000 W/m2 power density to the panel. In the ASTM G173, this solar radiation is quantified across the spectrum from 280 to 4000 nm.

To approximate this spectrum, several different types of light sources can be employed. In the past, xenon flashlamps were used because the light from these devices closely emulates the 6000 K temperature of the Sun. Other less expensive approaches include using halogen lamps with dichroic filters. Although halogen lamps have a greater temporal stability than their xenon counterparts, the color temperature of halogen lamps is far lower.

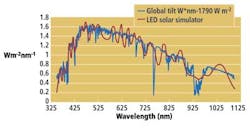

Although it is difficult to manufacture a light source that exactly matches the ASTM 1.5 spectrum with the necessary illumination intensity,ProPhotonix has developed an LED light source that closely approximates this spectrum (see figure).

The company has used its LED chip-on-board (COB) technology to engineer a light source that incorporates more than 20 individual LED types, each with a unique spectral response. By combining each of these individual light sources, the ASTM 1.5 spectrum (shown in red) can be closely approximated (shown in blue). Using this concept, the company has combined more than 2000 individual LED dies of the different wavelengths into a 400 × 400-mm flat-panel light source.

"With a lifetime up to 100,000 hours, a high temporal stability, and a color temperature that closely matches that of the Sun, the LED panel offers a cost-effective replacement to both xenon and halogen-based lighting alternatives," says Simon Stanley, managing director of ProPhotonix.

At present, the light source is currently being beta tested by a large manufacturer of photovoltaic cells to measure photoelectric conversion efficiency. In such a test system, the solar cell is illuminated and the voltage (V)-current (I) characteristics of the resulting output measured. From these VI measurements, the delivered power of the cell can be calculated and the efficiency of the cell determined since the delivered optical power is known.

Vision Systems Articles Archives