Novel Illumination

Andrew Wilson, Editor

In many machine-vision systems, the low power requirements and long lifetimes of LED lighting have made this technology the premiere choice for system developers. However, proper illumination of any specific part hinges upon choosing the correct color and type of illumination system.

Today, numerous ringlights, dome lights, backlights, and spotlights based on LED technology are available. Although these products have become commonplace, lighting vendors are building on these developments to offer different configurations of LED products to fulfill the needs of niche machine-vision applications.

In selecting lighting products, system developers must understand how illumination systems are used to increase the contrast of the features or markings on the part to be inspected. By increasing feature contrast, system integrators can often reduce the amount of time necessary to process captured images and thus the time it takes to develop a machine-vision system.

Configuration and color

Two of the most important considerations when choosing any type of lighting are the configuration of the light source and its spectral properties. Luckily, many vendors now provide rule-of-thumb charts and graphs with examples to highlight their products. Microscan, for example, provides a comparison of all of the most popular types of LED lighting on its web site at www.nerlite.com/Selector.html.

In addition to comparing the uses of backlights, ringlights, cloudy day illuminators, and other illumination products, J. Marcel Laflamme, now manager of LDDLIGHT.com, has also written extensively on how these products are used in different machine-vision applications (see “Lighting design enables vision systems,” Vision Systems Design, December 2005).

Because the spectral properties of parts may differ, products such as ringlights, backlights, diffuse illuminators, and others are all offered with LEDs that range from infrared to ultraviolet. Depending on the color or colors of the part to be inspected, the choice of which product to use can also be determined by a simple rule of thumb.

As John Merva of Advanced illumination points out, a color wheel can help determine what color to use in illuminating objects since using light that is the same color as an object makes it brighter in the scene and light that is an opposite color makes that color appear darker (see “Choosing illumination for vision systems,” Vision Systems Design, February 2004).

Benefits of backlights

Although simple rules can help determine the type and spectrum of illumination necessary for a particular application, a number of vendors have recently announced variations on their standard product ranges. The variations allow system developers to choose from an increasing range of more sophisticated lighting products to meet specific applications needs.

In many machine-vision systems, for example, it is only necessary to measure the outside dimensions of a part or features such as holes within the part. In these systems, LED backlighting provides a wide illumination area over which parts can pass.

For optimal illumination, many manufacturers use an array of surface-mount LEDs spaced evenly across the backlight and a diffuser to produce even lighting. Using LEDs in this manner results in a high-brightness backlight with a relatively thick display. To reduce thickness, some manufacturers also offer edge-lit backlights in which the LEDs are placed around the outside of the display and light transferred across the face of the display using a light-guiding diffusion plate. Moritex offers both types of backlights. The company’s MDBL Series provides a higher luminance than its edge-type MDBC Series, whereas the MDBC Series’ thinner design is more useful in applications with space constraints.

Phlox and Lumitex offer different variations of this technique in their range of machine-vision lights. Phlox uses a polymethacrylate pipe lit by a linear LED source in its range of backlights; Lumitex uses an optical fiber mounted on a back reflector to create lighting panels as thin as 0.013 in.

While these technologies have found success in applications where thin LED backlights are required, most manufacturers’ standard products are limited in area, measuring about 10 × 10 in. or less. However, in some applications, parts may be larger than the lighting under consideration; recognizing this, vendors have developed backlights that can be mated together to provide larger illuminated areas.

These products eliminate the standard bezel found in many backlights, allowing illumination to be provided across the complete area of the backlight. For example, products such as Microscan’s NERLITE Edge to Edge BL-47x59, BL-71x88, BL-100x100, and BL-50x200 backlights employ this technique, allowing multiple lights to be used together to increase illumination area (see Fig. 1).

On-axis illumination

Although LED backlights allow parts to be silhouetted for dimensional measurements, diffuse reflections from the lights can reduce edge measurement. Telecentric illumination must be used to improve gauging accuracy by eliminating parallax errors. To accomplish this, LED or fiberoptic lighting is coupled with a telecentric lens to provide a collimated light source.

Although these are more expensive than LED backlights, companies such as Opto Engineering recommended telecentric illumination for highly accurate measurement of round or cylindrical parts where diffusive backlights would offer poor performance.

LED methods are also available that use a number of different techniques to provide similar collimated light sources for on-axis illumination. Diffused lighting is generally offered in products such as on-axis lights that use a beamsplitter to direct light along the same axis as the camera lens and dome lights that incorporate an integrating sphere to produce coaxial illumination.

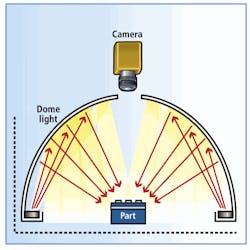

Whereas on-axis illumination products are used to evenly illuminate flat, shiny surfaces, dome lights increase the contrast between specular, diffuse, or absorptive surfaces. Many manufacturers, including Banner Engineering and LDDLIGHT.com, offer these as standard products in a number of different sizes and LED configurations.

On-axis, prism-based designs are often used in applications where the part to be measured is relatively small, whereas dome lights are now offered by companies such as Spectrum Illumination with diameters as large as 29 in. These are especially useful in vision systems designed for inspecting large parts such as tire rims that exhibit a high degree of specular reflectance (see Fig. 2).

In the past, dome lights were used in conjunction with coaxial illumination products to eliminate any nonuniform lighting effects. Companies such as Microscan have incorporated both these technologies into their range of cloudy day illuminators (CDIs) to eliminate this effect.

Flat domes

As a variation on the dome design, vendors such as LATAB and LDDLIGHT.com offer special versions of their dome lights called tunnel lighting or half-pipe reflection lights. This tunnel lighting is used to illuminate oblong objects or act as diffuse lighting for products on conveyor belts. LATAB offers tunnel lighting in a range of lengths from 119 to 371 mm in red, white, blue, green, UV, and IR. Similarly, LDDLIGHT.com’s IQD half-pipe reflection light is offered with white, red, green, or blue LED and incandescent lighting in lengths up to 350 mm (see Fig. 3).

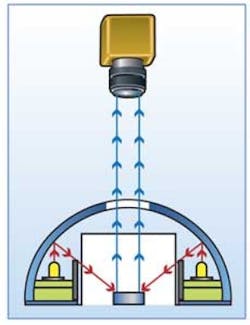

Probably the most important development in the last few years in dome lighting technology has been the introduction of flat domes or square domes that drastically reduce the space required to produce the CDI effect. At present, both CCS and LDDLIGHT.com offer these types of illumination systems (see Fig. 4).

CCS’s LFX Series, for example, uses a pattern of dots on the surface of a light-guiding diffuser plate to control light diffusion and transmission, making uniform, omnidirectional light possible. LEDs mounted in the rim emit light through the light-guiding diffuser plate and exit the surface as uniform, omnidirectional diffused light. This allows the 10-mm-thick illumination panel to produce either coaxial lighting or a dome effect depending on the working distance. A similar edge-lighting technology is used in the Square Dome IFH series from LDDLIGHT.com. Because the camera views the illuminated object directly through this panel, nonuniformities are eliminated.

In addition to developing innovative configurations such as flat dome lights, LED lighting manufacturers offer their products in a number of different wavelengths. Aside from the more traditional product offerings using white, red, green, and blue LEDs, UV and IR lights are becoming increasingly popular to perform more complex vision inspection applications. These include systems where materials to be inspected may exhibit fluorescence properties or where operators must be shielded from bright LED illumination. In other cases, illumination products that combine LEDs with multiple wavelengths are being used to reduce the number of inspection stations required to inspect multiple facets of complex parts.

Acknowledgment

The author would like to thank Marcel Laflamme, manager of LDDLIGHT.com, for his assistance in the preparation of this article.

Company Info

Advanced illumination

Rochester VT, USA

www.advill.com

Banner Engineering

Minneapolis, MN, USA

www.bannerengineering.com

CCS America

Burlington, MA, USA

www.ccsamerica.com

LATAB

Vällingby, Sweden

www.latab.se

LDDLIGHT.com

Milford, NH, USA

www.lddlight.com

Lumitex

Strongsville, OH, USA

www.lumitex.com

Microscan

Renton, WA, USA

www.microscan.com

Moritex

San Jose, CA, USA

www.moritexusa.com

Opto Engineering

Mantova, Italy

www.opto-engineering.com

Phlox

Aix en Provence, France

www.phlox-gc.com

Spectrum Illumination

Montague, MI, USA

www.spectrumillumination.com