When it comes to the food and beverage industry, the need for factory automation continues to grow. Machine vision systems that can sort and grade products by color, size, shape, visible defects, and internal defects provide valuable industrial automation solutions for the food industry.

In this particular case, the following machine vision systems from Lizotte provide automation and inspection for mainly seafood products:

- Herring roe sorter. This system takes soft x-ray images of the Herring and with proprietary software, evaluates the images to identify females with roe.

- Lobster cartilage finder. Using non-destructive soft x-ray, the system scans each claw on the conveyor and rejects the claws that contain cartilage.

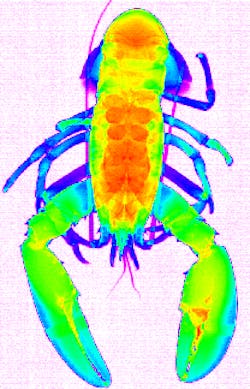

- Lobster grader. This system uses custom machine vision algorithms to evaluate x-ray images of lobster claws to identify the density of the meat content. Once it is found, lobsters are separated into different groups automatically.

- Mussel sorter. Soft x-ray technology is used to inspect mussels in the shell and ensures that defects are removed and only good product is sent to market.

- Scallop sorter. X-ray imaging is used to inspect the scallops to ensure that the shell has been removed. It processes 3,000 pieces per minute.

- Clam sorter. When the clams are in position for imaging, the machine vision sub-system is signaled and the grade data is integrated with the position data as tracking continues. Once the clam has advanced to the designated ejection station, it is transferred to a cross-belt with an air blast.

View more information on Lizotte machine vision food sorting solutions.

Also check out:

Code reader can track beers with 100% accuracy

Off-the-shelf components combine for granule and powder

Share your vision-related news by contacting James Carroll, Senior Web Editor, Vision Systems Design

To receive news like this in your inbox, click here.

About the Author

James Carroll

Former VSD Editor James Carroll joined the team 2013. Carroll covered machine vision and imaging from numerous angles, including application stories, industry news, market updates, and new products. In addition to writing and editing articles, Carroll managed the Innovators Awards program and webcasts.